Volume 11, Issue 3 (September 2024)

J. Food Qual. Hazards Control 2024, 11(3): 197-205 |

Back to browse issues page

Ethics code: UHAS-REC A.9 [41] 20-21

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Aboagye G, Sotobe B, Danyo R, Annan-Asare J, Tuah B, Daitey E et al . Quality of Reused Frying Oils from Various Fried Food Vendors in Ho Municipality. J. Food Qual. Hazards Control 2024; 11 (3) :197-205

URL: http://jfqhc.ssu.ac.ir/article-1-1124-en.html

URL: http://jfqhc.ssu.ac.ir/article-1-1124-en.html

Department of Nutrition and Dietetics, School of Allied Health Sciences, University of Health and Allied Sciences, Ho, Volta Region, Ghana , gaboagye@uhas.edu.gh

Full-Text [PDF 669 kb]

(2263 Downloads)

| Abstract (HTML) (1499 Views)

Full-Text: (257 Views)

Quality of Reused Frying Oils from Various Fried Food Vendors in Ho Municipality

G. Aboagye 1[*]* , B.A. Sotobe 1, R.E. Danyo 1, J. Annan-Asare 1,2, B. Tuah 1, E.A. Daitey 3, J. Jato 4

1. Department of Nutrition and Dietetics, School of Allied Health Sciences, University of Health and Allied Sciences, Ho, Volta Region, Ghana.

2. Department of Biochemistry and Biotechnology, College of Science, Kwame Nkrumah University of Science and Technology, Kumasi, Ashanti Region, Ghana.

3. Department of Pharmaceutical Chemistry and Microbiology, School of Pharmacy, University of Health and Allied Sciences, Ho, Volta Region, Ghana.

4. Department of Pharmacognosy and Herbal Medicine, School of Pharmacy, University of Health and Allied Sciences, Ho, Volta Region, Ghana.

HIGHLIGHTS

To cite: Aboagye G., Sotobe B.A., Danyo R.E., Annan-Asare J., Tuah B., Daitey E.A., Jato J. (2024). Quality of reused frying oils from various fried food vendors in Ho Municipality. Journal of Food Quality and Hazards Control. 11: 197-205.

Introduction

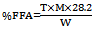

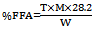

Where, T is the volume of KOH used; M is the molarity of KOH; W is the weight of sample used in g; and 28.2 is a constant for adjusting the units to a standard %FFA content.

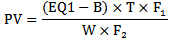

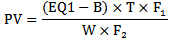

Determination of PV

Into a 250 ml conical flask, 1 ml of the oil sample was placed and 1 g of KI was added. The resultant content was dissolved with glacial acetic acid and chloroform in the ratio 3:2 v/v (30 ml) and was swirled gently. Complete dissolution was achieved by placing the conical flask and its content into a water bath at 60-65 °C for 5 min. Then, 20 ml of 5% KI solution was added and titrated against 0.01 N thiosulphate using starch as an indicator. The procedure was repeated to obtain an average titre. The PV of the oils was calculated using the formula (SI Analytics, 2018):

where:

EQ=Consumption of titrant until equivalent point

B=Blank titration value (ml)

T=Actual concentration of the titrant (ml)

M=Molecular weight

W=Weight of sample (g)

F1=Conversion factor (for acid number calculation=1,000)

F2=Conversion factor (for acid number calculation=1)

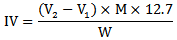

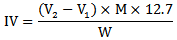

Determination of IV

A 0.33 g of oil sample was weighed into a dry glass stoppered bottle of 250 ml capacity and 10 ml of carbon tetrachloride was added. Thereafter, 20 ml of Wijs solution was added and allowed to stand in the dark for 30 min. Then, 15 ml of 10% KI solution and 100 ml of distilled water were added and then titrated against 0.1 N thiosulphate solution using starch as indicator just before the end point. A blank was prepared alongside the oil samples.

The results were calculated and reported as %Wijs using the formula (Codex Alimentarius, 2015):

Where, V2 is the volume of sodium thiosulphate used for the blank titration in ml; V1 is the volume of sodium thiosulphate used in for the actual titration in ml; M is the molarity of sodium thiosulphate in moles/L; W is the weight of the sample used in g; 12.7 is a constant used to convert from mEq sodium thiosulphate to g.

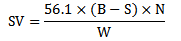

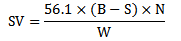

Determination of SV

An oil sample of 2.0 g was weighed into a conical flask and 25 ml of alcoholic KOH was added. The solution was heated in boiling water for 1 h and 1.0 ml of 1% phenolphthalein was added and titrated against 0.5 N HCl solution. A blank was carried out alongside the sample preparations. The results were calculated and reported as mg KOH/g using the formulae (Codex Alimentarius, 2015):

where:

56.1=A constant for the molecular weight of KOH in mg/mEq.

B=Volume of HCl used in the blank titration in ml.

S=Volume of HCl used in the sample titration in ml.

N=Normality of HCl solution in Eq/L.

W=Weight of sample used in g.

Determination of β-carotene

β-carotene content of the samples was analysed by ultraviolet spectrophotometer (Keats Manufacturing Co, USA) at 446 nm using the Malaysian Palm Oil Board (MPOB) method (Dauqan et al., 2011). The sample was homogenized and weighed to the nearest 0.0001 g into a 10 ml volumetric flask. The sample was dissolved in N-Hexane and diluted to the mark. The solution was transferred into a 1 cm quartz cuvette and the absorbance measured at 446 nm against N-Hexane. The β-carotene content of the different vegetable oils was defined and calculated using the formula (Codex Alimentarius, 2015):

Where, V is the volume used for analysis in ml; Aa is the absorbance of sample in nm; Ab is blank absorbance in au for background error correction; 383 is a constant for specific absorption coefficient of β-carotene; N is the dilution factor during sample preparation; and W is the weight of the sample in g for normalising β-carotene content to the sample weight.

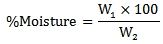

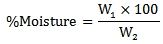

Determination of moisture content

The dry hot air oven was conditioned at 105 oC and moisture cans were placed in the oven for 1 h. The cans were removed, cooled in a desiccator and weighed. Then 5 g each of the samples was weighed into the various cans and placed in the oven for 3 h. After heating, the cans containing the respective samples were cooled in a desiccator and reweighed, and the weight of samples was subsequently calculated using the formula (Codex Alimentarius, 2015):

Where, W1 is the weight of water loss upon drying in g and W2 is the weight of the sample used in g.

Determination of rancidity

Equal volumes (2.0 ml) of each of the samples and chloroform were placed in a test tube. The mixture was stoppered and shaken well to dissolve the oil. Then 5.0 ml of 30% TCA in glacial acetic acid was added to the mixture. Subsequently, 1.0 ml of 1% phloroglucinol in glacial acetic acid was added to the mixture. Thereafter, the solution was incubated at 45 °C for 15 min in a hot air oven (Thermosafe Ltd, India). Upon removal, 2.0 ml of ethanol was added and the absorbance of the resultant solution was measured at 545 nm. An absorbance reading less than 0.15, greater than 0.20, and equal to 1.0 indicated no incipient, and high rancidity, respectively (Codex Alimentarius, 2015).

Data analysis

Data were entered into MS Excel version 2013, cleaned and exported to SPSS version 26.0 for analysis. Descriptive statistics were presented as frequencies and percentages. Continuous variables that were normally or not normally distributed were presented as mean±standard deviation (SD) or median (minimum-maximum), respectively. Comparison of means and medians were performed using T-test and Mann Whitney test respectively, while ANOVA was used for multiple comparisons. The significant level was set at p<0.05.

Results

Table 1 shows the characteristics and history of reused oil samples at the point of sample collection as reported by the respondents. A total of 20 samples were used for the study. 90% of the respondents used Frytol as their frying oil which represented the majority of the samples taken (18/20). The remaining two samples were sunflower and unoli oils representing 5% each. Regarding the duration of reusing the oils, a little above half of the respondents (11 (55%)), reused the oils within 5 days. The study also revealed that a quarter of the respondents changed their oils weekly, twice a week, or on monthly basis. However, 15% (3/20) never changed their oils and rather resorted to topping up with fresh oils. Plant-based foods such as yam, plantain, and potatoes were the most fried in the sampled oils (13 (65%)). Interestingly, some sellers fried both plants and animal products together. Majority of the sellers fried their foods between 10 and 20 min per food batch (15 (75%)), then stored the oil for a day before reuse (11 (55%)) and covered the oils in a plastic bottle (13 (65%)). The market place (16 (80%)) was the popular place of purchase of these oils although some were purchased from nearby shops (4 (20%)).

Table 1: Characteristics and history of oil samples at point of collection (Frequency)

Table 2 below shows the effect of storage condition and duration of reuse of the oils on FFA, moisture content, PV, IV, SV, β-carotene, and rancidity values. It was observed that aside from the lower p-value (0.0742) for FFA, recorded in oils used after 5 days, all the other parameters recorded higher p-values, the highest being 0.4095 for SV after reusing oils for more than 5 days except for rancidity which remained unchanged. However, these median differences were observed to be statistically insignificant (p>0.05).

Regarding the storage condition, even though not statistically comparable, FFA, IV, SV, and moisture content were descriptively higher but had lower p-values with the least being 0.0537 for FFA when the oils were stored in covered plastic bottles compared to storage in frying pans. The opposite was true for PV and β-carotene value.

The study also observed that the highest PV and SV values were apparently associated with oils in which plant products were fried while the highest FFA values were apparently associated with oils in which animal products were fried. However, oils in which both animal and plant products were fried had the highest values for moisture content and β-carotene. However, the median and mean differences were statistically insignificant with p-values of 0.8119 and 0.4095.

Furthermore, it was observed that the moisture content of all frying oils was significantly higher in oils that were only stored for a day compared to those that were stored for 2 days at a p-value of 0.049 (Table 3).

Regarding the duration of reuse, Lee et al. (2017) and Park et al. (2020) established that repeated frying in the same oil over time results in physicochemical changes to the quality of the oil. Specifically, Jurid et al. (2020) and Park et al. (2020) observed that FFA increase significantly with reuse of oils and Lee et al. (2017) observed that reusing soybean oil decreases its rancidity. Even though not statistically significant in the current study, a similar phenomenon was observed. The FFA value of oils reused within 5 days had lower FFA value (0.42 (0.14-1.26)) compared to reusing it more than 5 days (1.00 (0.28-4.70)), and increased as the number of reuse increased. This was in line with the study conducted by Giuffrè et al. (2017), where the FFA increased with reuse of the oil. This demonstrated that FFA is formed when degradation of triglyceride hydrolysis and hydroperoxide occur at high temperatures in the presence of moisture which was present in the food samples (Fekadu et al., 2024). However, the rancidity levels of the reused oils were all relatively stable. A plausible reason for these variations in the findings not only could be due to a difference in geographical location but also variation in the sampling technique and sample size. While the present study employed samples that were collected at random from fried food sellers in the community, the study by Park et al. (2020) employed reused oils under laboratory conditions i.e., produced from frying at intervals of 30 min and cooled to 25 °C for 100 times, and Jurid et al. (2020) also used laboratory conditions by heating the oil to 180 ±5 °C for 30 min.

The PV indicates primary oxidation and it is affected by duration of storage, frying temperature, and the reaction that occurs between air and the oil samples. The degree of unsaturated fatty acid is an important characteristic that influences oil oxidation. When double bonds in unsaturated fat are oxidized, peroxide is the principal oxidation product produced, and high readings indicate the degree of oxidation (Jurid et al., 2020). Regarding the duration of frying per food batch, Park et al. (2020) observed that PVs increased with the duration of frying, with a concomitant rise in the level of rancidity. Although not statistically significant (p˃0.05), this study also observed a rise in the level of PV from 10 to 20 min (5.80-55.80) to 21 to 40 min (11.50-32.30) frying time. Surprisingly, the PVs reduced from 41 to 60 min frying time (0.28-1.27). The current study also showed an increase in IVs instead of a linear decrease observed by Goburdhun et al. (2001). A plausible reason for this contrasting finding could be due to the fact that while the study by Goburdhun et al. (2001) employed a standard frying temperature of 180 °C for a total of 600 min at an interval of 90 min, the standard frying temperature for all samples in this study could not be ensured as the exact frying temperatures used by fried food sellers could not be established. Nonetheless, studies established that the level of unsaturation of oil increases with increasing temperature, hence, a rise in IV (Freire et al., 2012; Goburdhun et al., 2001; Jurid et al., 2020).

High temperatures can aid in the evaporation and removal of moisture from the oil. Higher temperatures can accelerate moisture evaporation, which helps to maintain oil quality. However, high temperature can cause the oil to oxidize and degrade, which can negatively affect its quality and taste (Fekadu et al., 2024). In consideration of the type of food fried in the reused oils, the authors of this study found that moisture content of the reused oils in which plant products were fried was higher (0.20-4.04) than those in which animal products were fried (0.19-1.60%) (Table 3). This observation corroborated favorably with a Malaysian study which also saw a rise in the moisture content of frying oil from 3.7±0.1 to 30.4% (w/w) when plant products such as potatoes were fried in the oil owing to the presence of moisture in the plant product (Fekadu et al., 2024; Jurid et al., 2020).

In addition, the current study observed significant reduction in the moisture content with respect to the duration of storage after frying with it. A moisture content of 0.20-4.04% was recorded with oils that were reused after a day compared to 0.60 that was recorded after 2 days (Table 3). A study by De Almeida et al. (2019) also established that duration of storage of oil after frying as well as its storage condition go a long way to influence its quality. The researchers found that both the storage at 25 °C and exposure to light induced oxidative reactions that culminated in increased FFA. In the current study, however, reused oils stored in covered plastic bottles were found to have higher FFA values (0.28-4.70) compared to those stored in covered frying pans (0.14-0.57). A possible explanation to this observed phenomenon could be due to the fact that although both reused oils were all likely stored at room temperature, those stored in plastic bottles had a greater chance of exposure to light owing to the transparent nature of the plastic bottles, hence, the observed relatively high FFA value. The current study also apparently observed a decreased moisture content of oils reused after 1 day compared to those used after 2 days while PVs were high in reused oils after 2 days compared to those used after a day.

Conclusions

Invariably, fried food quality depends largely on the quality of its frying oil. Hence, it is not without significance that when the quality of these oils is compromised, it could be detrimental to human health when consumed. Of all the qualities of reused oils assessed, moisture content of reused oils was observed to reduce significantly when oil is reused for more than 2 days.

In order to maintain the quality of oil and ensure good health of the general public through the consumption of foods fried in oil, sellers of fried foods must reduce the duration of storage of reused frying oil, and avoid storage conditions that expose oils to excess light.

Furthermore, a robust laboratory-standardized quality investigation of reused oil should be conducted to establish the effect of low-temperature long-time and high-temperature short-time as well as establish industrial standards for FFA, moisture content, PV, IV, and SV, carotene, and rancidity values locally.

Ethical consideration

This study did not involve any human or animal testing. Ethical approval was sought from the University of Health and Allied Sciences, Research Ethics Committee (UHAS-REC) of the Institute of Health Research. Following the ethical approval, the Institute issued the certificate number UHAS-REC A.9 [41] 20-21.

Conflicts of interest

The authors declare no conflict of interests.

Funding

Authors declared that no funding or grant was obtained for the study.

Authors’ contributions

G.A. conceptualized, wrote, validated, investigated, analysed data, provided resources, supervised the study; B.A.S. wrote the manuscript, analysed data, developed the methodology, and provided resources; R.E.D. conceptualized the research, wrote, validated, developed the methodology, and provided resources; J.A.-A. did the investigation, validated, analysed data, supervised, and provided resources; B.T. did the investigation, validated and supervised the study, developed the methodology, and provided resources; E.A.D. developed the methodology, investigated, and provided resources; J.J. investigated and validated the research, developed the methodology, and provided resources. All authors read and approved the final manuscript.

Acknowledgement

The authors wish to express their appreciation to Mr. Godsway Edem Kpene for the generous support during the laboratory investigations.

Codex Alimentarius. (2015). Standard for named vegatable oils. Codex Standard 210-1999. URL: https://www.fao.org/input/ download/standards/336/CXS_210e_2015.pdf. Accessed 10 March 2021.

Dauqan E., Sani H.A., Abdullah A., Muhamad H., Top G. (2011). Vitamin E and beta carotene composition in four different vegetable oils. American Journal of Applied Sciences. 8: 407-412. [DOI: 10.3844/ajassp.2011.407.412]

De Almeida D.T., Viana T.V., Costa M.M., Silva C.D.S., Feitosa S. (2019). Effects of different storage conditions on the oxidative stability of crude and refined palm oil, olein and stearin (Elaeis guineensis). Food Science and Technology. 39: 211-217. [DOI: 10.1590/fst.43317]

Fekadu D., Abera S., Weldemichael H. (2024). The influences of street food vendor frying equipment on the quality of frying oil. Heliyon. 10: e28293. [DOI: 10.1016/j.heliyon.2024.e28293]

Freire L.M.S., Filho J.R.C., Moura C.V.R., Soledade L.E.S., Stragevitch L., Cordeiro Â.M.T.M., Santos I.M.G., Souza A.G. (2012). Evaluation of the oxidative stability and flow properties of quaternary mixtures of vegetable oils for biodiesel production. Fuel. 95: 126-130. [DOI: 10.1016/j.fuel.2011.11.014]

Gadiraju T.V., Patel Y., Gaziano J.M., Djoussé L. (2015). Fried food consumption and cardiovascular health: a review of current evidence. Nutrients. 7: 8424-8430. [DOI: 10.3390/nu7105404]

Giuffrè A.M., Capocasale M., Zappia C., Poiana M. (2017). Influence of high temperature and duartion of heating on the sunflower seed oil properties for food use and bio-diesel production. Journal of Oleo Sciences. 66: 1193-1205. [DOI: 10.5650/jos.ess17109]

Goburdhun D., Jhaumeer-Laulloo S.B., Musruck R. (2001). Evaluation of soybean oil quality during conventional frying by FTIR and some chemical indexes. International Journal of Food Sciences and Nutrition. 52: 31-42. [DOI: 10.1080/ 09637480020027183]

Goswami G., Bora R., Rathore M.S. (2015). Oxidation of cooking oils due to repeated frying and human health. International Journal of Science Technology and Management. 4: 495-501.

Jahren A.H., Schubert B.A. (2010). Corn content of French fry oil from national chain vs. small business restaurants. Proceedings of the National Academy of Sciences. 107: 2099-2101. [DOI: 10.1073/pnas.0914437107]

Jurid L.S., Zubairi S.I., Kasim Z.M., Kadir I.A.A. (2020). The effect of repetitive frying on physicochemical properties of refined, bleached and deodorized Malaysian tenera palm olein during deep-fat frying. Arabian Journal of Chemistry. 13: 6149-6160. [DOI: 10.1016/j.arabjc.2020.05.015]

Lee J.-H., Park J.-M., Kim H.-J., Koh J.-H., Kim J.-M. (2017). Physicochemical changes in edible oils (soybean, canola, palm, and lard) and fried foods (pork cutlet and potato) depending on fry number. Korean Journal of Food Science and Technology. 49: 50-55. [DOI: 10.9721/KJFST.2017.49.1.50]. [Korean with English abstract]

Nkekesi B., Amenya P., Aboagye G. Kortei N.K. (2023). Street-vended grilled beef sausages as potential vehicles of bacterial and fungal pathogens: an exploratory survey in Ho, the capital city of the Volta Region of Ghana. Food Science and Nutrition. 11: 7013-7025. [DOI: 10.1002/fsn3.3625]

Oke E.K., Idowu M.A., Sobukola O.P., Adeyeye S.A.O., Akinsola A.O. (2017): Frying of food: a critical review. Journal of Culinary Science and Technology. 16: 107-127. [DOI: 10.1080/15428052.2017.1333936]

Park J.M., Koh J.H., Kim J.M. (2020). Determining the reuse of frying oil for fried sweet and sour pork according to type of oil and frying time. Food Science of Animal Resources. 40: 785-794. [DOI: 10.5851/kosfa.2020.e54]

SI Analytics. (2018). Determination of peroxide value (POV) in

fats and oils. Xylem Analytics Germany Sales GmbH & Co.

KG. Hattenbergstr, Germany. URL: https://www. xylemanalytics.com/en/File%20Library/Resource%20Library/ SIA/09%20Application%20Papers/UK/Peroxide-value_EN.pdf. Accessed 10 March 2021.

Venkata R.P., Subramanyam R. (2016). Evaluation of the deleterious health effects of consumption of repeatedly heated vegetable oil. Toxicology Reports. 3: 636-643. [DOI: 10.1016/j.toxrep. 2016.08.003]

Wang R., Qiao L., Wang J., Wang J., Zhang N., Chen H., Sun J., Wang S., Zhang Y. (2023). Effect of different vegetable oils on the flavor of fried green onion (Allium fistulosum L.) oil. Foods. 12: 1442. [DOI: 10.3390/foods12071442]

YSI. (2019). Determination of acid value and free fatty acids (FFA) in fats and oils. Xylem brand. Brannum Lane, Yellow Springs, USA. URL: https://www.ysi.com/File%20Library/ Documents/ Titration%20Applications/XA00080-FFA-Application-Note. pdf?srsltid=AfmBOooqJfrozxY6rc4x3u5TEK9FS9bX2qLPqkkh5IDA6SjSSd4nKGVQ. Accessed 14 March 2021.

G. Aboagye 1[*]*

1. Department of Nutrition and Dietetics, School of Allied Health Sciences, University of Health and Allied Sciences, Ho, Volta Region, Ghana.

2. Department of Biochemistry and Biotechnology, College of Science, Kwame Nkrumah University of Science and Technology, Kumasi, Ashanti Region, Ghana.

3. Department of Pharmaceutical Chemistry and Microbiology, School of Pharmacy, University of Health and Allied Sciences, Ho, Volta Region, Ghana.

4. Department of Pharmacognosy and Herbal Medicine, School of Pharmacy, University of Health and Allied Sciences, Ho, Volta Region, Ghana.

- The Free Fatty Acid increased with the duration of use of the oils.

- Oils stored in plastic bottles recorded higher Free Fatty Acid values compared to those stored in frying pans.

- Moisture content was higher in plant-based foods and lower in animal-based foods that were fried.

- Moisture content decreased as the number of reuses of oil increased.

| Article type Original article |

ABSTRACT Background: Frying makes food tasty; therefore, most people prefer the intake of fried foods to unfried foods. Oil for frying is mostly used again due to cost, and this can pose health hazards to the consumer. The aim of this study was to evaluate the quality of reused frying oils. Methods: Twenty samples of reused oils collected from fried food vendors in May 2021. Using an experimental study, the samples were analysed and Peroxide, Free Fatty Acid (FFA), Saponification, Iodine Values as well as rancidity and beta carotene were determined. Data from laboratory assays were analysed with Microsoft excel 2013 and SPSS v.26.0. Results: Moisture content was observed to decrease as median from 1.19% (0.20-4.04%) for oils reused after a day to 0.60% for oils reused after 2 days with a significant effect (p-value=0.049), indicating that the quality of reused frying oil was affected by repeated use. The moisture content was also observed to be higher in oils in which plant products were fried compared to those in which animal products were fried. The Peroxide Value was recorded as 16.80 (5.80-55.80) and 21.90 (11.50-32.30) mEq/kg for oils with 10-20 and 21-40 min frying times, respectively; whilst their moisture content decreased from 0.97 (0.19-2.55) to 0.68% (0.60-0.77%) for 10-20 and 21-40 min, respectively. The authors also observed that factors such as the duration of reuse and storage after frying, conditions of storage, type of food fried in the oil, and the period of frying per food batch impacted the quality attributes of the reused oils. The FFA composition for instance increased with the duration of use of the oils. Furthermore, oils stored in plastic bottles recorded higher FFA values compared to those stored in frying pans. Conclusion: The findings show the need for fried food vendors to reduce the duration of storage of reused frying oil, and avoid storage conditions that expose oils to excess light. Also, the development of quality standards for highly patronised oils needs to be established to ascertain the impact of low-temperature long-time and high-temperature short-time treatments of the oils among non-existent jurisdictions. © 2024, Shahid Sadoughi University of Medical Sciences. This is an open access article under the Creative Commons Attribution 4.0 International License. |

|

| Keywords Food Handling Fatty Acids Esters Oxidative Stress Peroxides. |

||

| Article history Received: 14 Dec 2023 Revised: 28 Apr 2024 Accept: 30 Aug 2024 |

||

| Abbreviation FFA=Free Fatty Acid IV=Iodine Value PV=Peroxide Value SV=Saponification Value |

Introduction

Frying as a cooking method is an efficient and popular means of cooking as it requires less expensive equipment and ingredients (Oke et al., 2017). Among the things that inform sellers of fried foods regarding the choice of oil include its viscosity, flavour, ability to smoke, and cost. Apparently, the cost mostly seems to influence utility, so much that these sellers resort to the reuse of frying oil (Fekadu et al., 2024). However, most people prefer the intake of fried food to unfried ones due to the pleasant sensory properties such as taste, flavor, and the crispy feel of most fried foods. Accordingly, the production of vegetable oil has increased over the years especially palm oil, canola oil, sunflower oil, and soybean oil (Wang et al., 2023).

Deep-frying method involves the full immersion of food into hot oil at a particular temperature. In the process of deep frying, the surface of food is cooked and forms a type of “seal” preventing further penetration by the oil. It is the moisture within the food that subsequently cooks the food (Venkata and Subramanyam, 2016). This method of cooking results in changes in the nutritional and sensory characteristics of food due to complex interactions between food and oil, as heat is involved (Oke et al., 2017). These complex interactions affect the quality of oils. At very high temperatures during frying, there is loss of nutritional value and quality of frying oil through complex chemical changes that occur such as oxidation, polymerization, and hydrolysis. These chemical changes lead to lipid peroxidation which generates volatile and non–volatile substances including Free Fatty Acids (FFAs), ketones, and trans fats. Moreover, during the process of water evaporation, there is a concomitant loss of heat labile nutrients such as proteins, vitamins, and antioxidants. In addition, exposure of oil to oxygen and high temperatures leads to oxidation of triacyl glycerides to hydro peroxides (Benmeziane et al., 2024). This, in turn, necessitates the preference of saturated and monounsaturated oils over polyunsaturated oils for frying as they are not easily reactive to oxygen (Benmeziane et al., 2024). When oil is heated repeatedly to boiling point, free radicals which can cause oxidative stress are formed (Venkata and Subramanyam, 2016). In addition, re-utility of cooking oil for frying changes not only the chemical properties but also the physical properties such as taste, foaming, and viscosity (Goswami et al., 2015; Park et al., 2020). Repetitive use of frying oil poses harm to health of consumers through oxidation of unsaturated fatty acids, which is influenced by the degree of unsaturation, heat, light, and oil processing antioxidants. Nonetheless, vendors of fried foods in most developing countries tend to reuse oils due to the relatively high cost of frying oil (Jahren and Schubert, 2010). Invariably, in Ho municipality in Volta Region of Ghana, most fried food vendors have the perception that change of oils after a single use is a waste of resource. As a result, most tend to reuse their oils several times. In the quest for more profit, most fried food vendors reuse their frying oils to the neglect of their health risks and implications (Fekadu et al., 2024; Gadiraju et al., 2015). The negligence of these food vendors to health risks could be partly attributed to the unavailability of data on the quality of reused oil and lack of education. It is against this backdrop that authors of this work sought to establish the quality of reused frying oils especially in Ho municipality. Also, frying remains the most widely used method of cooking, and hence, a risk to people’s health. Incidence of obesity and other non-communicable diseases related to fried foods is also on the rise due to increased consumption of fatty foods. To the authors knowledge, no data on the subject of quality of reused frying oil exist in Ghana, as a result, this research is the first of its kind to be documented, hence; the findings from this work consequently add to the literature on the quality of frying oils in Ghana and beyond. It also provides the basis for public awareness and stakeholder’s decision-making regarding the reuse of frying oil in applicable jurisdictions. Policymakers, healthcare organizations, and manufacturing professionals can benefit from the study's findings. Supported with this evidence, individuals can make knowledgeable choices on frying oil reuse. The influence on local businesses, street sellers, and households, and understanding that frying oil quality has a direct impact on health and wellness of individuals will greatly lead to making informed choices on the type, duration, and storage methods of oil. It further serves as the basis for more studies on the health risks of reusing frying oil for both commercial and domestic purposes, thus, it is necessary that the assessment of the quality attributes of reused frying oil be carried out to promote the health of the increasing number of the consuming public.

Study site

This study was carried out in Ho municipality. Ho is the capital city of the Volta region of Ghana.

Using online calculator (Hotjar sample size calculator), the sample size was determined to be 20 samples (Nkekesi et al., 2023).

Sampling technique

A purposive sampling technique was employed. Ho municipality was divided into the following locations: Ho main market, Trafalgar, Ahoe roundabout, Ho Technical University area Dome Calvary Road. By count, the aforementioned areas had a total of 52, 16, 11, 21, and 7 general sellers of fried foods; 12, 7, 5, 5, and 4 onsite fryers of foods, respectively. Reused oils were obtained from about half of these sellers selected from each stratum of onsite fryers i.e., 8, 4, 3, 3, and 2.

Sample collection

A total of twenty reused frying oil samples were collected from sellers of fried foods at night. These were placed into sterile bottles and transported to the pharmaceutical chemistry laboratory of the School of Pharmacy, University of Health, and Allied Sciences for analysis.

Reagents and equipment used

The reagents used included Wijs solution (Central Drug House, India), phenolphthalein (Suvchem, India), sodium thiosulphate (Anmol Chemicals, India), chloroform (Kemphasol, India), glacial acetic acid (ChemTrade International, Ghana), saturated potassium iodide (KI; Kemphasol, India), carbon tetrachloride (Kemphasol, India), trichloroacetic acid (TCA; Belami Fine Chemicals Pvt. Ltd., India), alcoholic potassium hydroxide (KOH; Gli-Therm Sp. ZO.O, Poland), hydrochloric acid solution (HCl; Penta Chem, Czechia), phloroglucinol (Kemphasol, India), N-Hexane (WTH GmbH, Germany), sodium hydroxide (NaOH; Newport Industries LTD, UK), starch (Kemphasol, India), and ethanol (Tauroquimica, Colombia).

Equipment included beakers, conical flasks, desiccators, burette, a retort stand (HDA, UK), water bath (Hach, Dubai), hot air oven (Labinda, India), and moisture cans (EIE Instruments PVT LTD, Ahmedabad).

The equipment and reagents were provided by the School of Pharmacy, University of Health and Allied Sciences.

Determination of FFA

Fifty ml of distilled ethanol was pipetted into a 250 ml conical flask. To this content, 1 ml of the oil sample and 2 ml of phenolphthalein were added. The content in the conical flask was then incubated at 60-65 °C in a water bath to warm. Enough 0.1 M KOH was added to produce a faint permanent pink color. Thereafter, 1 ml of oil sample was added to the neutralized alcohol and titrated against 0.1 M KOH. FFA present in the samples was calculated using the formula (YSI, 2019):

Deep-frying method involves the full immersion of food into hot oil at a particular temperature. In the process of deep frying, the surface of food is cooked and forms a type of “seal” preventing further penetration by the oil. It is the moisture within the food that subsequently cooks the food (Venkata and Subramanyam, 2016). This method of cooking results in changes in the nutritional and sensory characteristics of food due to complex interactions between food and oil, as heat is involved (Oke et al., 2017). These complex interactions affect the quality of oils. At very high temperatures during frying, there is loss of nutritional value and quality of frying oil through complex chemical changes that occur such as oxidation, polymerization, and hydrolysis. These chemical changes lead to lipid peroxidation which generates volatile and non–volatile substances including Free Fatty Acids (FFAs), ketones, and trans fats. Moreover, during the process of water evaporation, there is a concomitant loss of heat labile nutrients such as proteins, vitamins, and antioxidants. In addition, exposure of oil to oxygen and high temperatures leads to oxidation of triacyl glycerides to hydro peroxides (Benmeziane et al., 2024). This, in turn, necessitates the preference of saturated and monounsaturated oils over polyunsaturated oils for frying as they are not easily reactive to oxygen (Benmeziane et al., 2024). When oil is heated repeatedly to boiling point, free radicals which can cause oxidative stress are formed (Venkata and Subramanyam, 2016). In addition, re-utility of cooking oil for frying changes not only the chemical properties but also the physical properties such as taste, foaming, and viscosity (Goswami et al., 2015; Park et al., 2020). Repetitive use of frying oil poses harm to health of consumers through oxidation of unsaturated fatty acids, which is influenced by the degree of unsaturation, heat, light, and oil processing antioxidants. Nonetheless, vendors of fried foods in most developing countries tend to reuse oils due to the relatively high cost of frying oil (Jahren and Schubert, 2010). Invariably, in Ho municipality in Volta Region of Ghana, most fried food vendors have the perception that change of oils after a single use is a waste of resource. As a result, most tend to reuse their oils several times. In the quest for more profit, most fried food vendors reuse their frying oils to the neglect of their health risks and implications (Fekadu et al., 2024; Gadiraju et al., 2015). The negligence of these food vendors to health risks could be partly attributed to the unavailability of data on the quality of reused oil and lack of education. It is against this backdrop that authors of this work sought to establish the quality of reused frying oils especially in Ho municipality. Also, frying remains the most widely used method of cooking, and hence, a risk to people’s health. Incidence of obesity and other non-communicable diseases related to fried foods is also on the rise due to increased consumption of fatty foods. To the authors knowledge, no data on the subject of quality of reused frying oil exist in Ghana, as a result, this research is the first of its kind to be documented, hence; the findings from this work consequently add to the literature on the quality of frying oils in Ghana and beyond. It also provides the basis for public awareness and stakeholder’s decision-making regarding the reuse of frying oil in applicable jurisdictions. Policymakers, healthcare organizations, and manufacturing professionals can benefit from the study's findings. Supported with this evidence, individuals can make knowledgeable choices on frying oil reuse. The influence on local businesses, street sellers, and households, and understanding that frying oil quality has a direct impact on health and wellness of individuals will greatly lead to making informed choices on the type, duration, and storage methods of oil. It further serves as the basis for more studies on the health risks of reusing frying oil for both commercial and domestic purposes, thus, it is necessary that the assessment of the quality attributes of reused frying oil be carried out to promote the health of the increasing number of the consuming public.

Material and methods

Study design

The study design was experimental. This approach was selected because a set of procedures was systematically undertaken to test the hypothesis that reused frying oil does or does not have same quality as fresh frying oil. Laboratory procedures were carried out to determine the Peroxide Value (PV), FFA value, rancidity as well as Iodine Value (IV), Saponification Value (SV), moisture content, and beta-carotene content of the oil samples, since these parameters have been established as related to quality of frying oil.Study site

This study was carried out in Ho municipality. Ho is the capital city of the Volta region of Ghana.

Population and sample size determination

The study population consisted of onsite fried food vendors who operated their services solely with oils in Ho municipality. Using online calculator (Hotjar sample size calculator), the sample size was determined to be 20 samples (Nkekesi et al., 2023).

Sampling technique

A purposive sampling technique was employed. Ho municipality was divided into the following locations: Ho main market, Trafalgar, Ahoe roundabout, Ho Technical University area Dome Calvary Road. By count, the aforementioned areas had a total of 52, 16, 11, 21, and 7 general sellers of fried foods; 12, 7, 5, 5, and 4 onsite fryers of foods, respectively. Reused oils were obtained from about half of these sellers selected from each stratum of onsite fryers i.e., 8, 4, 3, 3, and 2.

Sample collection

A total of twenty reused frying oil samples were collected from sellers of fried foods at night. These were placed into sterile bottles and transported to the pharmaceutical chemistry laboratory of the School of Pharmacy, University of Health, and Allied Sciences for analysis.

Reagents and equipment used

The reagents used included Wijs solution (Central Drug House, India), phenolphthalein (Suvchem, India), sodium thiosulphate (Anmol Chemicals, India), chloroform (Kemphasol, India), glacial acetic acid (ChemTrade International, Ghana), saturated potassium iodide (KI; Kemphasol, India), carbon tetrachloride (Kemphasol, India), trichloroacetic acid (TCA; Belami Fine Chemicals Pvt. Ltd., India), alcoholic potassium hydroxide (KOH; Gli-Therm Sp. ZO.O, Poland), hydrochloric acid solution (HCl; Penta Chem, Czechia), phloroglucinol (Kemphasol, India), N-Hexane (WTH GmbH, Germany), sodium hydroxide (NaOH; Newport Industries LTD, UK), starch (Kemphasol, India), and ethanol (Tauroquimica, Colombia).

Equipment included beakers, conical flasks, desiccators, burette, a retort stand (HDA, UK), water bath (Hach, Dubai), hot air oven (Labinda, India), and moisture cans (EIE Instruments PVT LTD, Ahmedabad).

The equipment and reagents were provided by the School of Pharmacy, University of Health and Allied Sciences.

Determination of FFA

Fifty ml of distilled ethanol was pipetted into a 250 ml conical flask. To this content, 1 ml of the oil sample and 2 ml of phenolphthalein were added. The content in the conical flask was then incubated at 60-65 °C in a water bath to warm. Enough 0.1 M KOH was added to produce a faint permanent pink color. Thereafter, 1 ml of oil sample was added to the neutralized alcohol and titrated against 0.1 M KOH. FFA present in the samples was calculated using the formula (YSI, 2019):

Where, T is the volume of KOH used; M is the molarity of KOH; W is the weight of sample used in g; and 28.2 is a constant for adjusting the units to a standard %FFA content.

Determination of PV

Into a 250 ml conical flask, 1 ml of the oil sample was placed and 1 g of KI was added. The resultant content was dissolved with glacial acetic acid and chloroform in the ratio 3:2 v/v (30 ml) and was swirled gently. Complete dissolution was achieved by placing the conical flask and its content into a water bath at 60-65 °C for 5 min. Then, 20 ml of 5% KI solution was added and titrated against 0.01 N thiosulphate using starch as an indicator. The procedure was repeated to obtain an average titre. The PV of the oils was calculated using the formula (SI Analytics, 2018):

where:

EQ=Consumption of titrant until equivalent point

B=Blank titration value (ml)

T=Actual concentration of the titrant (ml)

M=Molecular weight

W=Weight of sample (g)

F1=Conversion factor (for acid number calculation=1,000)

F2=Conversion factor (for acid number calculation=1)

Determination of IV

A 0.33 g of oil sample was weighed into a dry glass stoppered bottle of 250 ml capacity and 10 ml of carbon tetrachloride was added. Thereafter, 20 ml of Wijs solution was added and allowed to stand in the dark for 30 min. Then, 15 ml of 10% KI solution and 100 ml of distilled water were added and then titrated against 0.1 N thiosulphate solution using starch as indicator just before the end point. A blank was prepared alongside the oil samples.

The results were calculated and reported as %Wijs using the formula (Codex Alimentarius, 2015):

Where, V2 is the volume of sodium thiosulphate used for the blank titration in ml; V1 is the volume of sodium thiosulphate used in for the actual titration in ml; M is the molarity of sodium thiosulphate in moles/L; W is the weight of the sample used in g; 12.7 is a constant used to convert from mEq sodium thiosulphate to g.

Determination of SV

An oil sample of 2.0 g was weighed into a conical flask and 25 ml of alcoholic KOH was added. The solution was heated in boiling water for 1 h and 1.0 ml of 1% phenolphthalein was added and titrated against 0.5 N HCl solution. A blank was carried out alongside the sample preparations. The results were calculated and reported as mg KOH/g using the formulae (Codex Alimentarius, 2015):

where:

56.1=A constant for the molecular weight of KOH in mg/mEq.

B=Volume of HCl used in the blank titration in ml.

S=Volume of HCl used in the sample titration in ml.

N=Normality of HCl solution in Eq/L.

W=Weight of sample used in g.

Determination of β-carotene

β-carotene content of the samples was analysed by ultraviolet spectrophotometer (Keats Manufacturing Co, USA) at 446 nm using the Malaysian Palm Oil Board (MPOB) method (Dauqan et al., 2011). The sample was homogenized and weighed to the nearest 0.0001 g into a 10 ml volumetric flask. The sample was dissolved in N-Hexane and diluted to the mark. The solution was transferred into a 1 cm quartz cuvette and the absorbance measured at 446 nm against N-Hexane. The β-carotene content of the different vegetable oils was defined and calculated using the formula (Codex Alimentarius, 2015):

Where, V is the volume used for analysis in ml; Aa is the absorbance of sample in nm; Ab is blank absorbance in au for background error correction; 383 is a constant for specific absorption coefficient of β-carotene; N is the dilution factor during sample preparation; and W is the weight of the sample in g for normalising β-carotene content to the sample weight.

Determination of moisture content

The dry hot air oven was conditioned at 105 oC and moisture cans were placed in the oven for 1 h. The cans were removed, cooled in a desiccator and weighed. Then 5 g each of the samples was weighed into the various cans and placed in the oven for 3 h. After heating, the cans containing the respective samples were cooled in a desiccator and reweighed, and the weight of samples was subsequently calculated using the formula (Codex Alimentarius, 2015):

Where, W1 is the weight of water loss upon drying in g and W2 is the weight of the sample used in g.

Determination of rancidity

Equal volumes (2.0 ml) of each of the samples and chloroform were placed in a test tube. The mixture was stoppered and shaken well to dissolve the oil. Then 5.0 ml of 30% TCA in glacial acetic acid was added to the mixture. Subsequently, 1.0 ml of 1% phloroglucinol in glacial acetic acid was added to the mixture. Thereafter, the solution was incubated at 45 °C for 15 min in a hot air oven (Thermosafe Ltd, India). Upon removal, 2.0 ml of ethanol was added and the absorbance of the resultant solution was measured at 545 nm. An absorbance reading less than 0.15, greater than 0.20, and equal to 1.0 indicated no incipient, and high rancidity, respectively (Codex Alimentarius, 2015).

Data analysis

Data were entered into MS Excel version 2013, cleaned and exported to SPSS version 26.0 for analysis. Descriptive statistics were presented as frequencies and percentages. Continuous variables that were normally or not normally distributed were presented as mean±standard deviation (SD) or median (minimum-maximum), respectively. Comparison of means and medians were performed using T-test and Mann Whitney test respectively, while ANOVA was used for multiple comparisons. The significant level was set at p<0.05.

Results

Table 1 shows the characteristics and history of reused oil samples at the point of sample collection as reported by the respondents. A total of 20 samples were used for the study. 90% of the respondents used Frytol as their frying oil which represented the majority of the samples taken (18/20). The remaining two samples were sunflower and unoli oils representing 5% each. Regarding the duration of reusing the oils, a little above half of the respondents (11 (55%)), reused the oils within 5 days. The study also revealed that a quarter of the respondents changed their oils weekly, twice a week, or on monthly basis. However, 15% (3/20) never changed their oils and rather resorted to topping up with fresh oils. Plant-based foods such as yam, plantain, and potatoes were the most fried in the sampled oils (13 (65%)). Interestingly, some sellers fried both plants and animal products together. Majority of the sellers fried their foods between 10 and 20 min per food batch (15 (75%)), then stored the oil for a day before reuse (11 (55%)) and covered the oils in a plastic bottle (13 (65%)). The market place (16 (80%)) was the popular place of purchase of these oils although some were purchased from nearby shops (4 (20%)).

Table 1: Characteristics and history of oil samples at point of collection (Frequency)

| Variable | Frequency | Percentage |

| Type of oil | ||

| Frytol | 18 | 90 |

| Sunflower | 1 | 5 |

| Unoli | 1 | 5 |

| Duration of reuse | ||

| ≤5 days | 11 | 55 |

| >5 days | 9 | 45 |

| Frequency of change | ||

| Daily | 2 | 10 |

| Twice a week | 5 | 25 |

| Weekly | 5 | 25 |

| Monthly | 5 | 25 |

| Never | 3 | 15 |

| Place of purchase | ||

| Market | 16 | 80 |

| Nearby shop | 4 | 20 |

| Foods fried in the oil | ||

| Plant products | 13 | 65 |

| Animal products | 5 | 25 |

| Both | 2 | 10 |

| Min of frying per food batch | ||

| 10-20 | 15 | 75 |

| 21-40 | 2 | 10 |

| 41-60 | 3 | 15 |

| Length of storage after frying | ||

| 1 day | 11 | 55 |

| 2 days | 1 | 5 |

| Overnight | 8 | 40 |

| How oil is stored after use | ||

| Covered plastic bottle | 13 | 65 |

| Covered frying pan | 6 | 30 |

| Uncovered frying pan | 1 | 5 |

Regarding the storage condition, even though not statistically comparable, FFA, IV, SV, and moisture content were descriptively higher but had lower p-values with the least being 0.0537 for FFA when the oils were stored in covered plastic bottles compared to storage in frying pans. The opposite was true for PV and β-carotene value.

The study also observed that the highest PV and SV values were apparently associated with oils in which plant products were fried while the highest FFA values were apparently associated with oils in which animal products were fried. However, oils in which both animal and plant products were fried had the highest values for moisture content and β-carotene. However, the median and mean differences were statistically insignificant with p-values of 0.8119 and 0.4095.

Furthermore, it was observed that the moisture content of all frying oils was significantly higher in oils that were only stored for a day compared to those that were stored for 2 days at a p-value of 0.049 (Table 3).

Table 2: Effect of duration of oil reuse and storage conditions on free fatty acid (FFA), peroxide value (PV), iodine value (IV), saponification values (SV), moisture content, β-carotene, and rancidity values (ANOVA)

Data are presented as median (min-max). The SV are presented as mean±Standard Deviation (SD).

Table 3: Effect of food type fried in oil and length of oil storage on free fatty acid (FFA), peroxide value (PV), iodine value (IV), saponification values (SV), moisture content, β-carotene, and rancidity values (ANOVA)

Data are presented as median (min-max). SVs are presented as mean±Standard Deviation (SD).

A*=foods of animal origin; B*=foods of plant origin; C*=foods of animal and plant origin

| Parameter | Total | Duration of reuse | P-value | Storage condition of oil | p-value | ||

| ≤5 days | >5 days | Covered plastic bottle | Covered frying pan | ||||

| FFA (%) | 0.50 (0.14-4.70) | 0.42 (0.14-1.26) | 1.00 (0.28-4.70) | 0.3006 | 0.70 (0.28-4.70) | 0.39 (0.14-0.57) | 0.0537 |

| PV (mEq/kg) | 16.30 (5.80-55.80) | 24.50 (9.60-55.80) | 15.30 (5.80-46.30) | 0.1819 | 15.80 (9.60-55.80) | 16.65 (5.80-43.40) | 0.8829 |

| IV (%) | 31.80 (15.40-35.70) | 31.40 (15.40-32.10) | 32.50 (27.20-35.70) | 0.0742 | 31.80 (27.20-35.70) | 31.40 (15.40-32.50) | 0.3978 |

| SV (mg KOH/ g oil) | 20.55±8.99 | 19.01±7.86 | 22.44±10.36 | 0.4095 | 23.25±7.73 | 15.85±7.50 | 0.1 |

| Moisture (%) | 0.88 (0.19-4.04) | 0.60 (0.19-4.04) | 1.19 (0.20-2.55) | 0.1744 | 1.19 (0.19-4.04) | 0.59 (0.20-0.97) | 0.1019 |

| βcarotene (%) | 0.30 (0.14-2.52) | 0.34 (0.17-2.52) | 0.30 (0.14-0.61) | 0.1979 | 0.30 (0.14-2.52) | 0.47 (0.19-1.86) | 0.577 |

| Rancidity (%) | 1.00 (1.00-1.86) | 1.00 (1.00-1.86) | 1.00 (1.00-1.00) | >0.9999 | 1.00 (1.00-1.86) | 1.00 (1.00-1.00) | >0.9999 |

Table 3: Effect of food type fried in oil and length of oil storage on free fatty acid (FFA), peroxide value (PV), iodine value (IV), saponification values (SV), moisture content, β-carotene, and rancidity values (ANOVA)

| Parameter | Food type fried in oil | p-value | Length of oil storage after frying | p-value | |||

| (A)* | (B)* | (C)* | 1 Day | 2 Days | |||

| FFA (%) | *0.57 (0.14-4.70) | *0.70 (0.42-1.27) | *0.35 (0.28-0.42) | 0.371 | 0.42 (0.14-4.70) | 0.42 (0.42-0.42) | 0.889 |

| PV (mEq/kg) | *17.60 (5.80-55.80) | *15.30 (11.5-32.3) | *17.20 (9.90-24.50) | 0.751 | 16.80 (5.80-46.30) | 32.30 (32.30-32.30) | 0.673 |

| IV (%) | *31.80 (15.40-35.70) | *31.80 (27.2-35.7) | *31.25 (30.70-31.80) | 0.944 | 32.10 (27.00-35.70) | 31.80 (31.80-31.80) | 0.0851 |

| SV (mg KOH/g oil) | *21.71±8.77 | *19.53±9.5 | *15.61±NA | 0.667 | 20.13±9.79 | 24.8±NA | 0.914 |

| Moisture(%) | *0.97 (0.20-4.04) | *0.60 (0.19-1.60) | *2.35 (2.14-2.55) | 0.107 | 1.19 (0.20-4.04) | 0.60 (0.60-0.60) | 0.049 |

| Β-carotene (%) | *0.28 (0.14-2.52) | *0.30 (0.26-0.34) | *0.52 (0.42-0.61) | 0.476 | 0.30 (0.14-2.52) | 0.34 (0.34-0.34) | 0.580 |

| Rancidity (%) | *1.00 (1.00-1.00) | *1.00 (1.00-1.00) | *1.43 (1.00-1.86) | >0.999 | 1.00 (1.00-1.86) | 1.00 (1.00-1.00) | >0.999 |

A*=foods of animal origin; B*=foods of plant origin; C*=foods of animal and plant origin

Table 4: Effect of duration of frying per food batch on free fatty acid (FFA), peroxide value (PV), iodine value (IV), saponification values (SV), moisture content,, β-carotene and rancidity values

Data are presented as median (min–max). (A)*, and (C)* of SVs are presented as mean±Standard Deviation (SD). A*=insignificant comparison for plant product and animal product; B*=insignificant comparison for animal product and both; C*=insignificant comparison for plant product and both.

| Parameter | Min of frying per food batch | p-value | ||

| (A)* | (B)* | (C)* | ||

| FFA (%) | *0.57 (0.14-4.70) | *0.42 (0.42-0.42) | *0.42 (0.28-1.27) | 0.859 |

| PV (mEq/kg) | *16.80 (5.80-55.80) | *21.90 (11.50-32.30) | *13.80 (9.60-32.60) | 0.857 |

| IV (%) | *31.40 (15.40-35.70) | *32.15 (31.80-32.50) | *32.10 (29.70-35.70) | 0.470 |

| SV (mg KOH/g oil) | *21.45±9.27 | *14.45 (4.10-24.80) | *20.13±3.78 | 0.608 |

| Moisture (%) | *0.97 (0.19-2.55) | *0.68 (0.60-0.77) | *1.60 (0.20-4.04) | 0.669 |

| β-carotene (%) | *0.28 (0.14-1.86) | *0.30 (0.26-0.34) | *0.66 (0.30-2.52) | 0.288 |

| Rancidity (%) | *1.00 (1.00-1.86) | *1.00 (1.00-1.00) | *1.00 (1.00-1.00) | >0.999 |

Discussion

The study sought to investigate the changes in the quality of reused oil subjected to varied conditions by selected fried food vendors particularly in Ho Municipality. A number of oil conditions such as duration of reuse, duration of storage after frying, condition of storage, type of food fried in it, and the period of frying per food batch were investigated to know how they affect the quality of the reused oil. The quality of these reused oils was assessed by determining their FFA, moisture content, PV, IV, SV, β-carotene, and rancidity values.Regarding the duration of reuse, Lee et al. (2017) and Park et al. (2020) established that repeated frying in the same oil over time results in physicochemical changes to the quality of the oil. Specifically, Jurid et al. (2020) and Park et al. (2020) observed that FFA increase significantly with reuse of oils and Lee et al. (2017) observed that reusing soybean oil decreases its rancidity. Even though not statistically significant in the current study, a similar phenomenon was observed. The FFA value of oils reused within 5 days had lower FFA value (0.42 (0.14-1.26)) compared to reusing it more than 5 days (1.00 (0.28-4.70)), and increased as the number of reuse increased. This was in line with the study conducted by Giuffrè et al. (2017), where the FFA increased with reuse of the oil. This demonstrated that FFA is formed when degradation of triglyceride hydrolysis and hydroperoxide occur at high temperatures in the presence of moisture which was present in the food samples (Fekadu et al., 2024). However, the rancidity levels of the reused oils were all relatively stable. A plausible reason for these variations in the findings not only could be due to a difference in geographical location but also variation in the sampling technique and sample size. While the present study employed samples that were collected at random from fried food sellers in the community, the study by Park et al. (2020) employed reused oils under laboratory conditions i.e., produced from frying at intervals of 30 min and cooled to 25 °C for 100 times, and Jurid et al. (2020) also used laboratory conditions by heating the oil to 180 ±5 °C for 30 min.

The PV indicates primary oxidation and it is affected by duration of storage, frying temperature, and the reaction that occurs between air and the oil samples. The degree of unsaturated fatty acid is an important characteristic that influences oil oxidation. When double bonds in unsaturated fat are oxidized, peroxide is the principal oxidation product produced, and high readings indicate the degree of oxidation (Jurid et al., 2020). Regarding the duration of frying per food batch, Park et al. (2020) observed that PVs increased with the duration of frying, with a concomitant rise in the level of rancidity. Although not statistically significant (p˃0.05), this study also observed a rise in the level of PV from 10 to 20 min (5.80-55.80) to 21 to 40 min (11.50-32.30) frying time. Surprisingly, the PVs reduced from 41 to 60 min frying time (0.28-1.27). The current study also showed an increase in IVs instead of a linear decrease observed by Goburdhun et al. (2001). A plausible reason for this contrasting finding could be due to the fact that while the study by Goburdhun et al. (2001) employed a standard frying temperature of 180 °C for a total of 600 min at an interval of 90 min, the standard frying temperature for all samples in this study could not be ensured as the exact frying temperatures used by fried food sellers could not be established. Nonetheless, studies established that the level of unsaturation of oil increases with increasing temperature, hence, a rise in IV (Freire et al., 2012; Goburdhun et al., 2001; Jurid et al., 2020).

High temperatures can aid in the evaporation and removal of moisture from the oil. Higher temperatures can accelerate moisture evaporation, which helps to maintain oil quality. However, high temperature can cause the oil to oxidize and degrade, which can negatively affect its quality and taste (Fekadu et al., 2024). In consideration of the type of food fried in the reused oils, the authors of this study found that moisture content of the reused oils in which plant products were fried was higher (0.20-4.04) than those in which animal products were fried (0.19-1.60%) (Table 3). This observation corroborated favorably with a Malaysian study which also saw a rise in the moisture content of frying oil from 3.7±0.1 to 30.4% (w/w) when plant products such as potatoes were fried in the oil owing to the presence of moisture in the plant product (Fekadu et al., 2024; Jurid et al., 2020).

In addition, the current study observed significant reduction in the moisture content with respect to the duration of storage after frying with it. A moisture content of 0.20-4.04% was recorded with oils that were reused after a day compared to 0.60 that was recorded after 2 days (Table 3). A study by De Almeida et al. (2019) also established that duration of storage of oil after frying as well as its storage condition go a long way to influence its quality. The researchers found that both the storage at 25 °C and exposure to light induced oxidative reactions that culminated in increased FFA. In the current study, however, reused oils stored in covered plastic bottles were found to have higher FFA values (0.28-4.70) compared to those stored in covered frying pans (0.14-0.57). A possible explanation to this observed phenomenon could be due to the fact that although both reused oils were all likely stored at room temperature, those stored in plastic bottles had a greater chance of exposure to light owing to the transparent nature of the plastic bottles, hence, the observed relatively high FFA value. The current study also apparently observed a decreased moisture content of oils reused after 1 day compared to those used after 2 days while PVs were high in reused oils after 2 days compared to those used after a day.

Conclusions

Invariably, fried food quality depends largely on the quality of its frying oil. Hence, it is not without significance that when the quality of these oils is compromised, it could be detrimental to human health when consumed. Of all the qualities of reused oils assessed, moisture content of reused oils was observed to reduce significantly when oil is reused for more than 2 days.

In order to maintain the quality of oil and ensure good health of the general public through the consumption of foods fried in oil, sellers of fried foods must reduce the duration of storage of reused frying oil, and avoid storage conditions that expose oils to excess light.

Furthermore, a robust laboratory-standardized quality investigation of reused oil should be conducted to establish the effect of low-temperature long-time and high-temperature short-time as well as establish industrial standards for FFA, moisture content, PV, IV, and SV, carotene, and rancidity values locally.

Ethical consideration

This study did not involve any human or animal testing. Ethical approval was sought from the University of Health and Allied Sciences, Research Ethics Committee (UHAS-REC) of the Institute of Health Research. Following the ethical approval, the Institute issued the certificate number UHAS-REC A.9 [41] 20-21.

Conflicts of interest

The authors declare no conflict of interests.

Funding

Authors declared that no funding or grant was obtained for the study.

Authors’ contributions

G.A. conceptualized, wrote, validated, investigated, analysed data, provided resources, supervised the study; B.A.S. wrote the manuscript, analysed data, developed the methodology, and provided resources; R.E.D. conceptualized the research, wrote, validated, developed the methodology, and provided resources; J.A.-A. did the investigation, validated, analysed data, supervised, and provided resources; B.T. did the investigation, validated and supervised the study, developed the methodology, and provided resources; E.A.D. developed the methodology, investigated, and provided resources; J.J. investigated and validated the research, developed the methodology, and provided resources. All authors read and approved the final manuscript.

Acknowledgement

The authors wish to express their appreciation to Mr. Godsway Edem Kpene for the generous support during the laboratory investigations.

References

Benmeziane F., Araba K., Belahcene A. (2024). Impact of deep-fat frying cycles on the physicochemical characteristics of two edible vegetable oils marketed in Algeria. The North African Journal of Food and Nutrition Research. 8: 21-31. [DOI: 10.51745/najfnr.8.17.21-31]Codex Alimentarius. (2015). Standard for named vegatable oils. Codex Standard 210-1999. URL: https://www.fao.org/input/ download/standards/336/CXS_210e_2015.pdf. Accessed 10 March 2021.

Dauqan E., Sani H.A., Abdullah A., Muhamad H., Top G. (2011). Vitamin E and beta carotene composition in four different vegetable oils. American Journal of Applied Sciences. 8: 407-412. [DOI: 10.3844/ajassp.2011.407.412]

De Almeida D.T., Viana T.V., Costa M.M., Silva C.D.S., Feitosa S. (2019). Effects of different storage conditions on the oxidative stability of crude and refined palm oil, olein and stearin (Elaeis guineensis). Food Science and Technology. 39: 211-217. [DOI: 10.1590/fst.43317]

Fekadu D., Abera S., Weldemichael H. (2024). The influences of street food vendor frying equipment on the quality of frying oil. Heliyon. 10: e28293. [DOI: 10.1016/j.heliyon.2024.e28293]

Freire L.M.S., Filho J.R.C., Moura C.V.R., Soledade L.E.S., Stragevitch L., Cordeiro Â.M.T.M., Santos I.M.G., Souza A.G. (2012). Evaluation of the oxidative stability and flow properties of quaternary mixtures of vegetable oils for biodiesel production. Fuel. 95: 126-130. [DOI: 10.1016/j.fuel.2011.11.014]

Gadiraju T.V., Patel Y., Gaziano J.M., Djoussé L. (2015). Fried food consumption and cardiovascular health: a review of current evidence. Nutrients. 7: 8424-8430. [DOI: 10.3390/nu7105404]

Giuffrè A.M., Capocasale M., Zappia C., Poiana M. (2017). Influence of high temperature and duartion of heating on the sunflower seed oil properties for food use and bio-diesel production. Journal of Oleo Sciences. 66: 1193-1205. [DOI: 10.5650/jos.ess17109]

Goburdhun D., Jhaumeer-Laulloo S.B., Musruck R. (2001). Evaluation of soybean oil quality during conventional frying by FTIR and some chemical indexes. International Journal of Food Sciences and Nutrition. 52: 31-42. [DOI: 10.1080/ 09637480020027183]

Goswami G., Bora R., Rathore M.S. (2015). Oxidation of cooking oils due to repeated frying and human health. International Journal of Science Technology and Management. 4: 495-501.

Jahren A.H., Schubert B.A. (2010). Corn content of French fry oil from national chain vs. small business restaurants. Proceedings of the National Academy of Sciences. 107: 2099-2101. [DOI: 10.1073/pnas.0914437107]

Jurid L.S., Zubairi S.I., Kasim Z.M., Kadir I.A.A. (2020). The effect of repetitive frying on physicochemical properties of refined, bleached and deodorized Malaysian tenera palm olein during deep-fat frying. Arabian Journal of Chemistry. 13: 6149-6160. [DOI: 10.1016/j.arabjc.2020.05.015]

Lee J.-H., Park J.-M., Kim H.-J., Koh J.-H., Kim J.-M. (2017). Physicochemical changes in edible oils (soybean, canola, palm, and lard) and fried foods (pork cutlet and potato) depending on fry number. Korean Journal of Food Science and Technology. 49: 50-55. [DOI: 10.9721/KJFST.2017.49.1.50]. [Korean with English abstract]

Nkekesi B., Amenya P., Aboagye G. Kortei N.K. (2023). Street-vended grilled beef sausages as potential vehicles of bacterial and fungal pathogens: an exploratory survey in Ho, the capital city of the Volta Region of Ghana. Food Science and Nutrition. 11: 7013-7025. [DOI: 10.1002/fsn3.3625]

Oke E.K., Idowu M.A., Sobukola O.P., Adeyeye S.A.O., Akinsola A.O. (2017): Frying of food: a critical review. Journal of Culinary Science and Technology. 16: 107-127. [DOI: 10.1080/15428052.2017.1333936]

Park J.M., Koh J.H., Kim J.M. (2020). Determining the reuse of frying oil for fried sweet and sour pork according to type of oil and frying time. Food Science of Animal Resources. 40: 785-794. [DOI: 10.5851/kosfa.2020.e54]

SI Analytics. (2018). Determination of peroxide value (POV) in

fats and oils. Xylem Analytics Germany Sales GmbH & Co.

KG. Hattenbergstr, Germany. URL: https://www. xylemanalytics.com/en/File%20Library/Resource%20Library/ SIA/09%20Application%20Papers/UK/Peroxide-value_EN.pdf. Accessed 10 March 2021.

Venkata R.P., Subramanyam R. (2016). Evaluation of the deleterious health effects of consumption of repeatedly heated vegetable oil. Toxicology Reports. 3: 636-643. [DOI: 10.1016/j.toxrep. 2016.08.003]

Wang R., Qiao L., Wang J., Wang J., Zhang N., Chen H., Sun J., Wang S., Zhang Y. (2023). Effect of different vegetable oils on the flavor of fried green onion (Allium fistulosum L.) oil. Foods. 12: 1442. [DOI: 10.3390/foods12071442]

YSI. (2019). Determination of acid value and free fatty acids (FFA) in fats and oils. Xylem brand. Brannum Lane, Yellow Springs, USA. URL: https://www.ysi.com/File%20Library/ Documents/ Titration%20Applications/XA00080-FFA-Application-Note. pdf?srsltid=AfmBOooqJfrozxY6rc4x3u5TEK9FS9bX2qLPqkkh5IDA6SjSSd4nKGVQ. Accessed 14 March 2021.

* Corresponding author (G. Aboagye)

* E-mail: gaboagye@uhas.edu.gh

ORCID ID: https://orcid.org/0000-0002-2725-2676

* E-mail: gaboagye@uhas.edu.gh

ORCID ID: https://orcid.org/0000-0002-2725-2676

Type of Study: Original article |

Subject:

Special

Received: 23/12/14 | Accepted: 24/08/30 | Published: 24/09/30

Received: 23/12/14 | Accepted: 24/08/30 | Published: 24/09/30

References

1. Benmeziane F., Araba K., Belahcene A. (2024). Impact of deep-fat frying cycles on the physicochemical characteristics of two edible vegetable oils marketed in Algeria. The North African Journal of Food and Nutrition Research. 8: 21-31. [DOI: 10.51745/najfnr.8.17.21-31] [DOI:10.51745/najfnr.8.17.21-31]

2. Codex Alimentarius. (2015). Standard for named vegatable oils. Codex Standard 210-1999. URL: https://www.fao.org/input/ download/standards/336/CXS_210e_2015.pdf. Accessed 10 March 2021.

3. Dauqan E., Sani H.A., Abdullah A., Muhamad H., Top G. (2011). Vitamin E and beta carotene composition in four different vegetable oils. American Journal of Applied Sciences. 8: 407-412. [DOI: 10.3844/ajassp.2011.407.412] [DOI:10.3844/ajassp.2011.407.412]

4. De Almeida D.T., Viana T.V., Costa M.M., Silva C.D.S., Feitosa S. (2019). Effects of different storage conditions on the oxidative stability of crude and refined palm oil, olein and stearin (Elaeis guineensis). Food Science and Technology. 39: 211-217. [DOI: 10.1590/fst.43317] [DOI:10.1590/fst.43317]

5. Fekadu D., Abera S., Weldemichael H. (2024). The influences of street food vendor frying equipment on the quality of frying oil. Heliyon. 10: e28293. [DOI: 10.1016/j.heliyon.2024.e28293] [DOI:10.1016/j.heliyon.2024.e28293] [PMID] [PMCID]

6. Freire L.M.S., Filho J.R.C., Moura C.V.R., Soledade L.E.S., Stragevitch L., Cordeiro Â.M.T.M., Santos I.M.G., Souza A.G. (2012). Evaluation of the oxidative stability and flow properties of quaternary mixtures of vegetable oils for biodiesel production. Fuel. 95: 126-130. [DOI: 10.1016/j.fuel.2011.11.014] [DOI:10.1016/j.fuel.2011.11.014]

7. Gadiraju T.V., Patel Y., Gaziano J.M., Djoussé L. (2015). Fried food consumption and cardiovascular health: a review of current evidence. Nutrients. 7: 8424-8430. [DOI: 10.3390/nu7105404] [DOI:10.3390/nu7105404] [PMID] [PMCID]

8. Giuffrè A.M., Capocasale M., Zappia C., Poiana M. (2017). Influence of high temperature and duartion of heating on the sunflower seed oil properties for food use and bio-diesel production. Journal of Oleo Sciences. 66: 1193-1205. [DOI: 10.5650/jos.ess17109] [DOI:10.5650/jos.ess17109] [PMID]

9. Goburdhun D., Jhaumeer-Laulloo S.B., Musruck R. (2001). Evaluation of soybean oil quality during conventional frying by FTIR and some chemical indexes. International Journal of Food Sciences and Nutrition. 52: 31-42. [DOI: 10.1080/ 09637480020027183] [DOI:10.1080/09637480020027183] [PMID]

10. Goswami G., Bora R., Rathore M.S. (2015). Oxidation of cooking oils due to repeated frying and human health. International Journal of Science Technology and Management. 4: 495-501.

11. Jahren A.H., Schubert B.A. (2010). Corn content of French fry oil from national chain vs. small business restaurants. Proceedings of the National Academy of Sciences. 107: 2099-2101. [DOI: 10.1073/pnas.0914437107] [DOI:10.1073/pnas.0914437107] [PMID] [PMCID]

12. Jurid L.S., Zubairi S.I., Kasim Z.M., Kadir I.A.A. (2020). The effect of repetitive frying on physicochemical properties of refined, bleached and deodorized Malaysian tenera palm olein during deep-fat frying. Arabian Journal of Chemistry. 13: 6149-6160. [DOI: 10.1016/j.arabjc.2020.05.015] [DOI:10.1016/j.arabjc.2020.05.015]

13. Lee J.-H., Park J.-M., Kim H.-J., Koh J.-H., Kim J.-M. (2017). Physicochemical changes in edible oils (soybean, canola, palm, and lard) and fried foods (pork cutlet and potato) depending on fry number. Korean Journal of Food Science and Technology. 49: 50-55. [DOI: 10.9721/KJFST.2017.49.1.50]. [Korean with English abstract] [DOI:10.9721/KJFST.2017.49.1.50]

14. Nkekesi B., Amenya P., Aboagye G. Kortei N.K. (2023). Street-vended grilled beef sausages as potential vehicles of bacterial and fungal pathogens: an exploratory survey in Ho, the capital city of the Volta Region of Ghana. Food Science and Nutrition. 11: 7013-7025. [DOI: 10.1002/fsn3.3625] [DOI:10.1002/fsn3.3625] [PMID] [PMCID]

15. Oke E.K., Idowu M.A., Sobukola O.P., Adeyeye S.A.O., Akinsola A.O. (2017): Frying of food: a critical review. Journal of Culinary Science and Technology. 16: 107-127. [DOI: 10.1080/15428052.2017.1333936] [DOI:10.1080/15428052.2017.1333936]

16. Park J.M., Koh J.H., Kim J.M. (2020). Determining the reuse of frying oil for fried sweet and sour pork according to type of oil and frying time. Food Science of Animal Resources. 40: 785-794. [DOI: 10.5851/kosfa.2020.e54] [DOI:10.5851/kosfa.2020.e54] [PMID] [PMCID]

17. SI Analytics. (2018). Determination of peroxide value (POV) in fats and oils. Xylem Analytics Germany Sales GmbH & Co. KG. Hattenbergstr, Germany. URL: https://www. xylemanalytics.com/en/File%20Library/Resource%20Library/ SIA/09%20Application%20Papers/UK/Peroxide-value_EN.pdf. Accessed 10 March 2021.

18. Venkata R.P., Subramanyam R. (2016). Evaluation of the deleterious health effects of consumption of repeatedly heated vegetable oil. Toxicology Reports. 3: 636-643. [DOI: 10.1016/j.toxrep. 2016.08.003] [DOI:10.1016/j.toxrep.2016.08.003] [PMID] [PMCID]

19. Wang R., Qiao L., Wang J., Wang J., Zhang N., Chen H., Sun J., Wang S., Zhang Y. (2023). Effect of different vegetable oils on the flavor of fried green onion (Allium fistulosum L.) oil. Foods. 12: 1442. [DOI: 10.3390/foods12071442] [DOI:10.3390/foods12071442] [PMID] [PMCID]

20. YSI. (2019). Determination of acid value and free fatty acids (FFA) in fats and oils. Xylem brand. Brannum Lane, Yellow Springs, USA. URL: https://www.ysi.com/File%20Library/ Documents/ Titration%20Applications/XA00080-FFA-Application-Note. pdf?srsltid=AfmBOooqJfrozxY6rc4x3u5TEK9FS9bX2qLPqkkh5IDA6SjSSd4nKGVQ. Accessed 14 March 2021.

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |