Volume 11, Issue 1 (March 2024)

J. Food Qual. Hazards Control 2024, 11(1): 26-38 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Solefack E, Tiencheu B, Zokou R, Tiwo C, Kohole A, Teboukeu G, et al . Microbiological Quality of commercial Soy Cheese (Tofu) Skewers and Determination of Critical Control Points during Production in the West Region of Cameroon. J. Food Qual. Hazards Control 2024; 11 (1) :26-38

URL: http://jfqhc.ssu.ac.ir/article-1-1128-en.html

URL: http://jfqhc.ssu.ac.ir/article-1-1128-en.html

E.N. Solefack

, B. Tiencheu *

, B. Tiencheu *

, R. Zokou

, R. Zokou

, C.T. Tiwo

, C.T. Tiwo

, A.H.F. Kohole

, A.H.F. Kohole

, G.B. Teboukeu

, G.B. Teboukeu

, S.H. Ndomou

, S.H. Ndomou

, F.D. Tonfack

, F.D. Tonfack

, J.M. Klang

, J.M. Klang

, M.H. Womeni

, M.H. Womeni

, B. Tiencheu *

, B. Tiencheu *

, R. Zokou

, R. Zokou

, C.T. Tiwo

, C.T. Tiwo

, A.H.F. Kohole

, A.H.F. Kohole

, G.B. Teboukeu

, G.B. Teboukeu

, S.H. Ndomou

, S.H. Ndomou

, F.D. Tonfack

, F.D. Tonfack

, J.M. Klang

, J.M. Klang

, M.H. Womeni

, M.H. Womeni

Department of Biochemistry, and Molecular Biology, Faculty of Science, University of Buea, P.O. Box 63, Buea-Cameroon , tiencheu.bernard@ubuea.cm

Full-Text [PDF 410 kb]

(1675 Downloads)

| Abstract (HTML) (1693 Views)

Full-Text: (6 Views)

Microbiological Quality of commercial Soy Cheese (Tofu) Skewers and Determination of Critical Control Points during Production in the West Region of Cameroon

E.N. Solefack 1, B. Tiencheu 2** , R. Zokou 1, C.T. Tiwo 3, A.H.F. Kohole 1, G.B. Teboukeu 4,

S.H. Ndomou 1,5, F.D. Tonfack 2, J.M. Klang 1, M.H. Womeni 1

1. Research Unit of Biochemistry of Medicinal Plants, Food Sciences and Nutrition, Department of Biochemistry, University of Dschang, P.O. Box 67, Dschang-Cameroon

2. Department of Biochemistry, and Molecular Biology, Faculty of Science, University of Buea, P.O. Box 63, Buea-Cameroon

3. Department of Processing, and Quality Control of Aquatic Products, Institute of Fisheries, and Aquatic Sciences at Yabassi, University of Douala, P.O. Box 7236 Douala-Cameroon

4. Department of Biochemistry Faculty of Science University of Bamenda, P.O. Box 39, Bambili- Cameroon

5. CRESA Forêt-Bois, Faculty of Agronomy, and Agricultural Science, University of Dschang P.O. Box 138, Yaoundé- Cameroon

HIGHLIGHTS

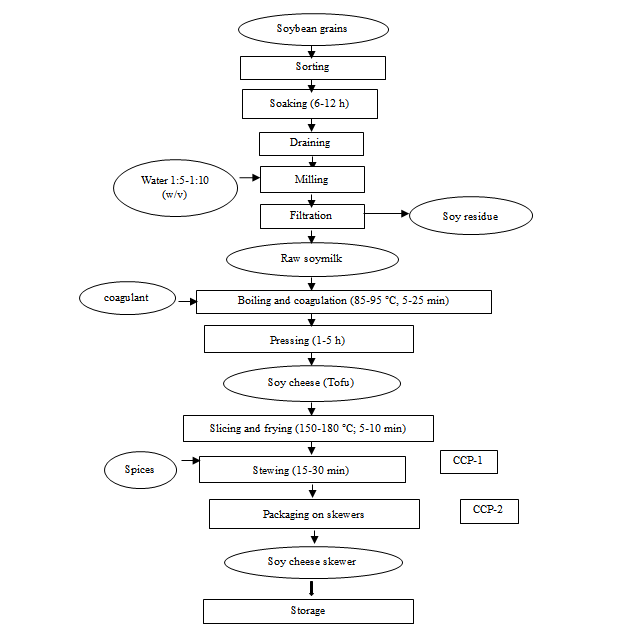

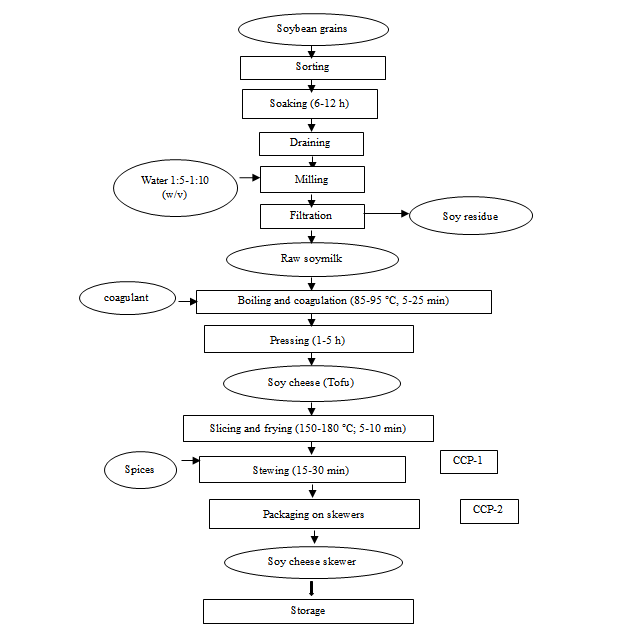

Figure 1: Flow diagram of soy cheese skewer production

CCP=Critical Control Pointulant

-Hazard analysis

Analysis of potential hazards that may be present at different steps are demonstrated in Table 2. From the flow diagram, hazard analysis was accomplished on every involved production step with the identification of potential hazards (chemical, biological, and physical) susceptible to affect the quality of the final product. Potential biological hazards consist of bacteria, and fungi from working tools, flies, domestic animals, workers, water sources, and containers. Chemical hazards seemed to be heavy metals from the grinder, rust in machines, anti-nutritional components in food, free radicals from repeated use of frying oil, and prohibited additives. Potential physical hazards contained stones, sand, dirt, death insects, and damaged grains. The monitoring procedures and control procedures were specific to the type of danger detected in the production step.

Table 3: Mean microbial loads (Log Colony Forming Unit (CFU)/g) of intermediate products, and soy cheese skewer during production

* standard limit recommended in finished product by the European commission for each microorganism (EC, 2005).

values with the same small letter within a group are not significantly different, and values with the same capital letter between different groups are not significantly different (p>0.05) according to Duncan multiple range test with One-way ANOVA.

TMAB=Total Mesophilic Aerobic Bacteria; S=slurry; SM=soymilk; FSC=fresh soy cheese; SSC= stewed soy cheese; SSCS=soy cheese skewer; ND=not detected; +=present.

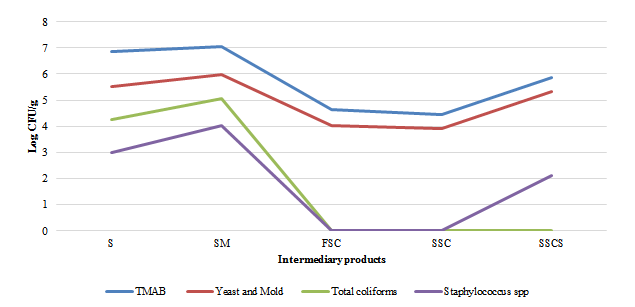

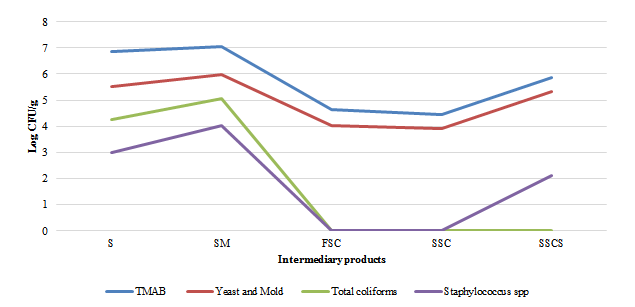

Figure 2: Change in mean microbial load counts during soy cheese skewer production process

CFU=Colony Forming Units;TMAB=Total Mesophilic Aerobic Bacteria;S=slurry; SM=soymilk; FSC=fresh soy cheese; SSC=stewed soy cheese; SSCS=soy cheese skewer

E.N. Solefack 1, B. Tiencheu 2**

S.H. Ndomou 1,5, F.D. Tonfack 2, J.M. Klang 1, M.H. Womeni 1

1. Research Unit of Biochemistry of Medicinal Plants, Food Sciences and Nutrition, Department of Biochemistry, University of Dschang, P.O. Box 67, Dschang-Cameroon

2. Department of Biochemistry, and Molecular Biology, Faculty of Science, University of Buea, P.O. Box 63, Buea-Cameroon

3. Department of Processing, and Quality Control of Aquatic Products, Institute of Fisheries, and Aquatic Sciences at Yabassi, University of Douala, P.O. Box 7236 Douala-Cameroon

4. Department of Biochemistry Faculty of Science University of Bamenda, P.O. Box 39, Bambili- Cameroon

5. CRESA Forêt-Bois, Faculty of Agronomy, and Agricultural Science, University of Dschang P.O. Box 138, Yaoundé- Cameroon

- The microbial load in commercial soy cheese skewers was unsatisfactory in regarding some microorganisms identified.

- The production process of soy cheese involved some critical points were control must be done to assure the safety of the final product.

- Commercial soy cheese skewer samples were of poor microbiological quality.

| Article type Original article |

ABSTRACT Background: In several cities of Cameroon, the consumption of soy cheese skewers commonly known as “soybean soya” is becoming very common in the streets. Its consumption is increasing thereby encouraging its local production using household methods. Food contamination from processing to consumption is becoming a serious health concern. Therefore, the purpose of this study was to ascertain the microbiological quality of soy cheese skewers sold in some markets and the Critical Control Points (CCPs) in the production process. Methods: Samples were collected in June and August 2022 from different vendors, stored in sterile plastic laminas and placed in a pack containing ice and taken to the laboratory for the determination of the microbiological quality. In order to determine CCPs based on microbiological hazard, samples of slurry, soymilk, fresh soy cheese, stewed soy cheese, and stewed soy cheese skewers were collected from different producers at different production steps and analyzed for microbial contaminations. Results: Results of samples collected from the markets indicated Total Mesophilic Aerobic Bacteria between 4.87 to 7.79 log Colony Forming Unit (CFU)/g, where 86% of the samples were higher than the normal; yeast and mold counts ranged from 2.84 to 5.91 CFU/g; staphylococci, and total coliforms ranged from 0 to 5.17 and 0 to 2.37 log CFU/g, present in 59 and 72% of samples, respectively. Conclusion: Most commercial soy cheese skewer samples showed poor microbiological quality. To reduce these contaminations, preventive measures should be put in place at CCPs (stewing and packaging on skewers) to ensure the safety of food. © 2024, Shahid Sadoughi University of Medical Sciences. This is an open access article under the Creative Commons Attribution 4.0 International License. |

|

| Keywords Soybean Cheese Contamination Hazard Analysis and Critical Control Points Cameroon |

||

| Article history Received: 17 Aug 2023 Revised: 2 Nov 2023 Accepted: 5 Mar 2024 |

||

| Acronyms and abbreviations CCPs=Critical Control Points CFU=Colony Forming Unit HACCP=Hazards Analysis Critical Control points RTE=Ready-to-Eat TMAB=Total Mesophilic Aerobic Bacteria |

To cite: Solefack E.N., Tiencheu B., Zokou R., Tiwo C.T., Kohole A.H.F., Teboukeu G.B., Ndomou S.H., Tonfack F.D., Klang J.M., Womeni M.H. (2024). Microbiological quality of commercial soy cheese (tofu) skewers and determination of critical control points during production in the West region of Cameroon. Journal of Food Quality and Hazards Control. 11: 26-38.

Introduction

Introduction

In sub-Saharan Africa, eating habits are changing due to the increase in the production and consumption of a wide variety of street foods. Street foods are typically Ready-to-Eat (RTE) foods, beverages prepared, and/or sold by vendors, particularly in the streets and other public places (FAO, 2009). These foods have some cultural significance and are generally inexpensive, convenient, affordable, and tasty. In Cameroon, there exists a wide variety of street foods including roasted and fried fish, meat, plantains, bread, eggs, fruits (Edima et al., 2014). Soybean and soybean products (oil, yoghurt, and tofu) for human nutrition are acquiring more and more popularity (Anirban et al., 2017; Zhang and Qin, 2019). One of the most popular of these soy products is tofu. Tofu is a product obtained from the curdling of hot soymilk with a coagulant (acid, salt, and enzyme) (Zhang et al., 2018). It originates from China and has become very popular worldwide due to an increasing knowledge of its nutritional and health benefits. In fact, tofu contains about 50% proteins, 27% fat (comprising mostly polyunsaturated fatty acids and very low saturated fats), and the remaining is made of carbohydrates and minerals (Yakubu and Amuzat, 2012; Zinia et al., 2022). It is cholesterol-free, rich in high-quality proteins, and particularly beneficial for individuals who want to limit or eliminate the consumption of animal protein. It can reduce the risk of developing a variety of chronic diseases, including cancer, cardiovascular diseases, abdominal body fat, osteoporosis, lowering cholesterol levels, and relieving menopausal symptoms (Qin et al., 2022).

Tofu is broadly consumed in two main forms depending on the consumers’ preference: fresh or unprocessed tofu which is produced directly from soy milk, and processed tofu that is made from fresh tofu (Zinia et al., 2022). In many developing countries like Cameroon, tofu is generally processed as stew and consumed in the form of soy cheese skewers (tofu skewers), commonly known as “soybean soya." Soy cheese skewers (tofu skewers) are new popular food obtained by processing fresh tofu and are becoming very popular in the streets and markets of many localities. It was formerly unknown to the general public, but is now regarded as a boneless meat that is skilfully obtained from soybeans, is inexpensively available on the streets, and delights the taste buds of consumers (Oboh, 2006; Zhang and Qin, 2019).

With the expensiveness of life, the sale and consumption of street foods is very common in developing countries and greatly contribute to enhancing the economies of these countries. Despite the socio-economic and nutritional importance of soy cheese skewers, they are associated with certain risks, generally of a microbial nature, just like many other street foods, when it is not well processed, stored, transported, and sold. Food-borne illnesses, which are typically brought on by bio-contamination with bacteria and/or fungi that cause illnesses like cholera, hepatitis, dysentery, and typhoid, sicken about 600 million people worldwide (FAO and WH0, 2019; Moelyaningrum, 2019).

The processing of soy cheese skewers involves a complex interaction of numerous factors and operations before the final product is obtained are generally made at household levels, requiring the absolute implementation of food safety procedures to ensure public health. In order to ensure food safety throughout the food chain, and prevent food-borne diseases, concrete processes including the application of the Codex Alimentarius guidelines on general principles of food hygieneas well as the analysis of Critical Control Points (CCPs) should be taken during the processing of street foods. The implementation of a Hazard Analysis and Critical Control Points (HACCPs) system is an internationally recognized tool used to evaluate hazards in a production process in order to establish appropriate systems of control based on prevention rather than the final product. This case facilitates the identification, evaluation, and control of significant hazards (CAC, 2009). Many authors have investigated the microbiological quality of fresh or unprocessed tofu (Aluko et al., 2014). Ananchaipattana et al. (2012) studied the rate of contamination and the types of food borne pathogens in unpackaged and packaged tofu sold in Thai market and concluded that the hygiene practices should be improved in order to reduce the risk of food poisoning and food spoilage. The same was true of Oluwole and Prudent (2020) as well as Zokou et al. (2022), who evaluated the microbiological quality of commercial soymilk sold in Akure, Nigeria, and egusi pudding in the city of Yaoundé, Cameroon, respectively. On the other hand, Sapieja (2017) explored the implementation of a HACCP plan during the production of blue-mold tofu in order to identify CCPs. Although many studies have demonstrated the microbiological quality of fresh or unprocessed tofu, to date, few data have been reported concerning the microbiological quality of commercial soy cheese available in the streets and its production process. Therefore, our study aimed to conduct a HACCP in the production process of soy cheese skewer in the West region with a focus on microbiological hazards.

Materials and methods

Study area

This descriptive study was carried out in the West region of Cameroon (Bafoussam, Dschang, Mbouda, Bangangte local markets) in June and August 2022. These city markets consisted of individuals from both the rural and urban areas. The West region was chosen based on the fact that it is one of the main producers of soybean. Markets were chosen according to their frequency in the sale of soy cheese skewers.

Collection of commercial soy cheese skewer samples

During commercialization, approximately ten different soy cheese skewers, weighing between 100 to 150 g were randomly collected from each of the 22 vendors and placed in sterilized polyethylene bags, put in an ice box, and transported to the Research Unit of Biochemistry of Medicinal Plants, Food Sciences and Nutrition (URBPMAN), laboratory of the Department of Biochemistry of the University of Dschang, Cameroon, for analysis at the same day. Because they are markets where soy cheese skewers are sold at least twice a week, therefore the various collection sites were selected.

Determination of CCPs

The decision tree developed by the Codex Alimentarius Commission (2009) on food hygiene was applied to identify CCPs in the production of soy cheese skewers. The different steps were analysed as shown on Figure 1 which represent the flowchart of processing soy cheese including CCPs. The critical limit for biological hazard evaluated the content in bacteria (Total Mesophilic Aerobic Bacteria (TMAB), total coliform, Staphylococcus spp., and Salmonella spp.), and fungi (yeast and mold) in slurry soymilk, fresh soy cheese, stewed soy cheese, and soy cheese skewer.

Tofu is broadly consumed in two main forms depending on the consumers’ preference: fresh or unprocessed tofu which is produced directly from soy milk, and processed tofu that is made from fresh tofu (Zinia et al., 2022). In many developing countries like Cameroon, tofu is generally processed as stew and consumed in the form of soy cheese skewers (tofu skewers), commonly known as “soybean soya." Soy cheese skewers (tofu skewers) are new popular food obtained by processing fresh tofu and are becoming very popular in the streets and markets of many localities. It was formerly unknown to the general public, but is now regarded as a boneless meat that is skilfully obtained from soybeans, is inexpensively available on the streets, and delights the taste buds of consumers (Oboh, 2006; Zhang and Qin, 2019).

With the expensiveness of life, the sale and consumption of street foods is very common in developing countries and greatly contribute to enhancing the economies of these countries. Despite the socio-economic and nutritional importance of soy cheese skewers, they are associated with certain risks, generally of a microbial nature, just like many other street foods, when it is not well processed, stored, transported, and sold. Food-borne illnesses, which are typically brought on by bio-contamination with bacteria and/or fungi that cause illnesses like cholera, hepatitis, dysentery, and typhoid, sicken about 600 million people worldwide (FAO and WH0, 2019; Moelyaningrum, 2019).

The processing of soy cheese skewers involves a complex interaction of numerous factors and operations before the final product is obtained are generally made at household levels, requiring the absolute implementation of food safety procedures to ensure public health. In order to ensure food safety throughout the food chain, and prevent food-borne diseases, concrete processes including the application of the Codex Alimentarius guidelines on general principles of food hygieneas well as the analysis of Critical Control Points (CCPs) should be taken during the processing of street foods. The implementation of a Hazard Analysis and Critical Control Points (HACCPs) system is an internationally recognized tool used to evaluate hazards in a production process in order to establish appropriate systems of control based on prevention rather than the final product. This case facilitates the identification, evaluation, and control of significant hazards (CAC, 2009). Many authors have investigated the microbiological quality of fresh or unprocessed tofu (Aluko et al., 2014). Ananchaipattana et al. (2012) studied the rate of contamination and the types of food borne pathogens in unpackaged and packaged tofu sold in Thai market and concluded that the hygiene practices should be improved in order to reduce the risk of food poisoning and food spoilage. The same was true of Oluwole and Prudent (2020) as well as Zokou et al. (2022), who evaluated the microbiological quality of commercial soymilk sold in Akure, Nigeria, and egusi pudding in the city of Yaoundé, Cameroon, respectively. On the other hand, Sapieja (2017) explored the implementation of a HACCP plan during the production of blue-mold tofu in order to identify CCPs. Although many studies have demonstrated the microbiological quality of fresh or unprocessed tofu, to date, few data have been reported concerning the microbiological quality of commercial soy cheese available in the streets and its production process. Therefore, our study aimed to conduct a HACCP in the production process of soy cheese skewer in the West region with a focus on microbiological hazards.

Materials and methods

Study area

This descriptive study was carried out in the West region of Cameroon (Bafoussam, Dschang, Mbouda, Bangangte local markets) in June and August 2022. These city markets consisted of individuals from both the rural and urban areas. The West region was chosen based on the fact that it is one of the main producers of soybean. Markets were chosen according to their frequency in the sale of soy cheese skewers.

Collection of commercial soy cheese skewer samples

During commercialization, approximately ten different soy cheese skewers, weighing between 100 to 150 g were randomly collected from each of the 22 vendors and placed in sterilized polyethylene bags, put in an ice box, and transported to the Research Unit of Biochemistry of Medicinal Plants, Food Sciences and Nutrition (URBPMAN), laboratory of the Department of Biochemistry of the University of Dschang, Cameroon, for analysis at the same day. Because they are markets where soy cheese skewers are sold at least twice a week, therefore the various collection sites were selected.

Determination of CCPs

The decision tree developed by the Codex Alimentarius Commission (2009) on food hygiene was applied to identify CCPs in the production of soy cheese skewers. The different steps were analysed as shown on Figure 1 which represent the flowchart of processing soy cheese including CCPs. The critical limit for biological hazard evaluated the content in bacteria (Total Mesophilic Aerobic Bacteria (TMAB), total coliform, Staphylococcus spp., and Salmonella spp.), and fungi (yeast and mold) in slurry soymilk, fresh soy cheese, stewed soy cheese, and soy cheese skewer.

Figure 1: Flow diagram of soy cheese skewer production

CCP=Critical Control Pointulant

Soy cheese production process

During the production process, seven producers were randomly selected and observed. Soybean grains (1,000 g) were sorted and soaked in water at room temperature for 6-12 h. Soaked beans were drained and milled in a public grinding machine with additional water. The obtained slurry after grinding was homogenized with excess water and filtered using a fine cloth or bags to separate soy waste (okara) from the soymilk. The soymilk was then heated (85-95 °C) and immediately it started boiling an appropriate coagulant was added. The formed curd was poured into a fine clothe and pressed using different heavy materials. At the end of this step, the fresh pressed soy cheese was sliced into appropriate shapes, fried in hot oil, stewed (with spices), and finally packed by putting on skewers to form soy cheese skewers as shown on Figure 1.

Collection of sample during production process

At different production steps, approximately 75 g of samples including soybean slurry, soybean milk, fresh soy cheese, stewed soy cheese, and soy cheese skewer were collected in sterile polyethylene bags, stored in an icebox, and taken to the Research Unit of Biochemistry of Medicinal Plants, Food Sciences and Nutrition (URBPMAN), laboratory of the Department of Biochemistry of the University of Dschang, Cameroon, for analysis.

Microbiological analysis of different samples

-Sample processing

Samples of commercial soy cheese skewer, slurry, soybean milk, fresh soy cheese, stewed soy cheese, and soy cheese skewer were analysed for the presence of bacteria, fungi, and coliforms. Briefly, 25 g of each sample was weighed aseptically and diluted into a conical flask containing 225 ml of buffered peptone water (Hameau, Germany) then homogenized. From this preparation, serial dilutions (10-1-10-4) were made according to ISO 6887-1 (2017).

-Microbiological analysis

The determination of TMAB was carried out using the pour plate method NF ISO 4833-1 (2013). The different samples (100 µl) were spread on 12.5 ml Plate Count Agar (PCA; LiofilChem, Italy) in petri dishes and incubated at 30±1 °C for a period of 48 h under aerobic conditions. For total coliform detection by the spread plate method NF ISO 4832 (2006), 100 µl of diluted samples were spread on the surface of sterilized, and solidified 12.5 ml MacConkey Agar (MCA; LiofilChem, Italy) followed by incubation at 37 °C for 24 h. The presence of milky white colonies on the surface of petri dishes were considered to be coliforms. The presence of Salmonella spp. in soy cheese skewer was determined using the method proposed by ISO 6579-1 (2017). Salmonella spp. was isolated by inoculating 100 µl of the samples on Salmonella and Shigella Agar (SSA; Himedia, India), and allowed for incubation for 18-24 h at 37 °C. Uncoloured colonies with black centers were considered as Salmonella spp. The normalized NF ISO 6888-1 (2021) method was used for the enumeration of Staphylococcus spp. One hundred µl of each dilution was inoculated on the surface of 12.5 ml Mannitol Salt Agar (MSA; LiofilChem, Italy). White colonies observed on MSA were counted as Staphylococcus spp. Yeast and mold were isolated by using the NF ISO 21527-1 (2008) method. Briefly, 100 µl of sample was placed on 12.5 ml of Potatoes Dextrose Agar (PDA; LiofilChem, Italy) with chloramphenicol and incubated for 3 to 5 days at 25 °C.

-Plate counting

After the different incubation periods, well individualized colonies on petri dishes were counted and the average results from duplicates expressed as log Colony Forming Units (CFU)/g.

Statistical analysis

Data was expressed as means±Standard Deviation (SD) using Microsoft Excel. One-way ANOVA was used for statistical analysis and the differences between the various groups of samples were evaluated using the Duncan’s Multiple Range test to compare the means with IBM SPSS 22 software (SPSS Inc., IBM Corporation, Chicago, USA). The significant differences were set at p<0.05.

During the production process, seven producers were randomly selected and observed. Soybean grains (1,000 g) were sorted and soaked in water at room temperature for 6-12 h. Soaked beans were drained and milled in a public grinding machine with additional water. The obtained slurry after grinding was homogenized with excess water and filtered using a fine cloth or bags to separate soy waste (okara) from the soymilk. The soymilk was then heated (85-95 °C) and immediately it started boiling an appropriate coagulant was added. The formed curd was poured into a fine clothe and pressed using different heavy materials. At the end of this step, the fresh pressed soy cheese was sliced into appropriate shapes, fried in hot oil, stewed (with spices), and finally packed by putting on skewers to form soy cheese skewers as shown on Figure 1.

Collection of sample during production process

At different production steps, approximately 75 g of samples including soybean slurry, soybean milk, fresh soy cheese, stewed soy cheese, and soy cheese skewer were collected in sterile polyethylene bags, stored in an icebox, and taken to the Research Unit of Biochemistry of Medicinal Plants, Food Sciences and Nutrition (URBPMAN), laboratory of the Department of Biochemistry of the University of Dschang, Cameroon, for analysis.

Microbiological analysis of different samples

-Sample processing

Samples of commercial soy cheese skewer, slurry, soybean milk, fresh soy cheese, stewed soy cheese, and soy cheese skewer were analysed for the presence of bacteria, fungi, and coliforms. Briefly, 25 g of each sample was weighed aseptically and diluted into a conical flask containing 225 ml of buffered peptone water (Hameau, Germany) then homogenized. From this preparation, serial dilutions (10-1-10-4) were made according to ISO 6887-1 (2017).

-Microbiological analysis

The determination of TMAB was carried out using the pour plate method NF ISO 4833-1 (2013). The different samples (100 µl) were spread on 12.5 ml Plate Count Agar (PCA; LiofilChem, Italy) in petri dishes and incubated at 30±1 °C for a period of 48 h under aerobic conditions. For total coliform detection by the spread plate method NF ISO 4832 (2006), 100 µl of diluted samples were spread on the surface of sterilized, and solidified 12.5 ml MacConkey Agar (MCA; LiofilChem, Italy) followed by incubation at 37 °C for 24 h. The presence of milky white colonies on the surface of petri dishes were considered to be coliforms. The presence of Salmonella spp. in soy cheese skewer was determined using the method proposed by ISO 6579-1 (2017). Salmonella spp. was isolated by inoculating 100 µl of the samples on Salmonella and Shigella Agar (SSA; Himedia, India), and allowed for incubation for 18-24 h at 37 °C. Uncoloured colonies with black centers were considered as Salmonella spp. The normalized NF ISO 6888-1 (2021) method was used for the enumeration of Staphylococcus spp. One hundred µl of each dilution was inoculated on the surface of 12.5 ml Mannitol Salt Agar (MSA; LiofilChem, Italy). White colonies observed on MSA were counted as Staphylococcus spp. Yeast and mold were isolated by using the NF ISO 21527-1 (2008) method. Briefly, 100 µl of sample was placed on 12.5 ml of Potatoes Dextrose Agar (PDA; LiofilChem, Italy) with chloramphenicol and incubated for 3 to 5 days at 25 °C.

-Plate counting

After the different incubation periods, well individualized colonies on petri dishes were counted and the average results from duplicates expressed as log Colony Forming Units (CFU)/g.

Statistical analysis

Data was expressed as means±Standard Deviation (SD) using Microsoft Excel. One-way ANOVA was used for statistical analysis and the differences between the various groups of samples were evaluated using the Duncan’s Multiple Range test to compare the means with IBM SPSS 22 software (SPSS Inc., IBM Corporation, Chicago, USA). The significant differences were set at p<0.05.

Results

Microbiological analysis of commercial soy-cheese skewers samples

The mean counts of different samples of commercial soy cheese skewer collected from different markets are shown in Table 1. Analysis on commercial soy cheese skewer revealed that they contained several microorganisms with microbial counts varying from one sample to the other.

All the samples had TMAB varying from 4.87±0.88 to 7.79±0.14 log CFU/g. The highest count was recorded in sample from Mbouda (7.79±0.14 log CFU/g), and the lowest from Bafoussam (4.87±0.88 log CFU/g). Yeast and mold counts were found in all examined samples, ranging from 2.84±0.21 to 5.91±0.36 log CFU/g, with the highest coming from Bangangte and the lowest from Dschang. Staphylococcus spp. counts were between 0 and 5.17 log CFU/g, and present in 59% of samples. The average total coliform counts varied from to 0-4.84 log CFU/g. Salmonella spp. was absent in all analysed samples.

The mean counts of different samples of commercial soy cheese skewer collected from different markets are shown in Table 1. Analysis on commercial soy cheese skewer revealed that they contained several microorganisms with microbial counts varying from one sample to the other.

All the samples had TMAB varying from 4.87±0.88 to 7.79±0.14 log CFU/g. The highest count was recorded in sample from Mbouda (7.79±0.14 log CFU/g), and the lowest from Bafoussam (4.87±0.88 log CFU/g). Yeast and mold counts were found in all examined samples, ranging from 2.84±0.21 to 5.91±0.36 log CFU/g, with the highest coming from Bangangte and the lowest from Dschang. Staphylococcus spp. counts were between 0 and 5.17 log CFU/g, and present in 59% of samples. The average total coliform counts varied from to 0-4.84 log CFU/g. Salmonella spp. was absent in all analysed samples.

Table 1: Mean microbial loads (log Colony Forming Unit (CFU)/g) of different samples of commercial soy cheese skewer collected from local markets

* standard limit recommended in finished product by the European commission for each microorganism (EC, 2005).

Values with same letters within a column are not significantly different (p>0.05) according to Duncan’ multiple range test with one-way ANOVA.

ND=Not Detected; TMAB=Total Mesophilic Aerobic Bacteria

| City | Sellers | TMAB (<5.47 log CFU/g)* |

Total coliforms (<2 log CFU/g)* |

Staphylococcus spp. (<2 log CFU/g)* |

Yeast and molds (<2 log CFU/g)* |

Salmonella spp. (Absent)* |

|

| Bangangte | 1 | 7.60±0.01 jk | 0.00±0.00 a | 3.15±0.21 b | 4.80±0.14 defg | ND | |

| 2 | 7.34±0.02 hijk | 2.34±0.02 b | 4.70±0.11 e | 5.39±0.04 i | ND | ||

| 3 | 6.11±0.04 cd | 2.11±0.04 b | 4.11±0.04 c | 5.77±0.08 j | ND | ||

| 4 | 6.00±0.00 bc | 0.00±0.00 a | 5.08±0.12 f | 4.23±0.33 c | ND | ||

| 5 | 7.05±0.40 fghij | 0.00±0.00 a | 3.99±0.06 c | 5.91±0.36 j | ND | ||

| Bafoussam | 1 | 6.20 ±0.17 cde | 3.47±0.00 d | 4.11±0.04 c | 4.61±0.04 d | ND | |

| 2 | 6.64±0.00 defg | 3.24±0.01 cd | 0.00±0.00 a | 4.77±0.04 def | ND | ||

| 3 | 6.71±0.20 defgh | 4.84±0.06 f | 0.00±0.00 a | 4.91±0.03 defgh | ND | ||

| 4 | 4.87±0.88 a | 0.00±0.00 a | 0.00±0.00 a | 3.23±0.33 b | ND | ||

| 5 | 7.26±0.22 ghijk | 0.00 ±0.00 a | 4.09±0.00 c | 5.18±0.00 ghi | ND | ||

| 6 | 7.31±0.39 hijk | 3.17±0.00 c | 5.17±0.00 f | 5.09±0.17 efghi | ND | ||

| 7 | 7.37±0.20 ijk | 3.01±0.04 c | 0.00±0.00 a | 5.17±0.03 fghi | ND | ||

| 8 | 6.30±0.00 cde | 0.00±0.00 a | 0.00±0.00 a | 3.87±0.24 c | ND | ||

| Dschang | 1 | 6.62±0.21 cde | 0.00±0.00 a | 0.00±0.00 a | 3.30±0.42 b | ND | |

| 2 | 6.60±0.00 cdef | 0.00±0.00 a | 0.00±0.00 a | 4.73±0.05 de | ND | ||

| 3 | 6.82±0.49 efghi | 0.00±0.00 a | 0.00±0.00 a | 2.84±0.21 a | ND | ||

| 4 | 6.41±0.02 cde | 0.00±0.00 a | 0.00±0.00 a | 3.27±0.10 b | ND | ||

| Mbouda | 1 | 7.31±0.02 hijk | 0.00±0.00 a | 4.60±0.27 de | 4.74±0.15 de | ND | |

| 2 | 7.06±0.00 fghij | 2.37±0.00 b | 5.12±0.06 f | 5.23±0.11 hi | ND | ||

| 3 | 5.47±0.00 b | 3.96±0.00 e | 4.41±0.08 d | 3.92±0.03 c | ND | ||

| 4 | 7.79±0.14 k | 0.00±0.00 a | 4.73±0.11 e | 5.35±0.09 i | ND | ||

| 5 | 7.61±0.10 jk | 0.00±0.00 a | 5.08±0.19 f | 5.36±0.19 i | ND | ||

Values with same letters within a column are not significantly different (p>0.05) according to Duncan’ multiple range test with one-way ANOVA.

ND=Not Detected; TMAB=Total Mesophilic Aerobic Bacteria

HACCP plan for the determination of CCPs

-Flow diagram in the production of soy cheese skewer

-Flow diagram in the production of soy cheese skewer

|

Coagulant

|

-Hazard analysis

Analysis of potential hazards that may be present at different steps are demonstrated in Table 2. From the flow diagram, hazard analysis was accomplished on every involved production step with the identification of potential hazards (chemical, biological, and physical) susceptible to affect the quality of the final product. Potential biological hazards consist of bacteria, and fungi from working tools, flies, domestic animals, workers, water sources, and containers. Chemical hazards seemed to be heavy metals from the grinder, rust in machines, anti-nutritional components in food, free radicals from repeated use of frying oil, and prohibited additives. Potential physical hazards contained stones, sand, dirt, death insects, and damaged grains. The monitoring procedures and control procedures were specific to the type of danger detected in the production step.

Table 2: Analysis of potential hazards at each production step

| Processing steps | Type of hazard | Critical limits | Monitoring procedure | Control measures |

| Sorting | physical: Presence of stones, sand, dirt, death insects, damaged grains | Absence of stones, sand, dirt, death insects, damaged grains | Visual control of grains to ensure they are free of physical hazards | Use baskets, sort well, wash grains |

| Soaking of grains | physical: Presence of stones, sand, dirt, death insects, damaged grains Chemical: presence of anti-nutritional elements due to poor soaking time, and temperature, heavy metals, and pesticides. Biological: contamination by bacteria from water source |

Absence of stones, sand, dirt, death insects, damaged grains Complete absence of anti-nutritional factors, heavy metals, and residues of pesticides. Absence of microorganisms responsible of bio contaminations |

Visual control of grains to ensure they are safe Determination of the presence of anti-nutritional factors Regular microbiological analysis Regular microbiological analysis of water used |

Sort well, wash grains Respect, and control the time (6-12 h), and temperature (ambient temperature) of soaking Make sure water source is free from contaminants |

| Milling/grinding | Physical: Rust and corrosion of the grinding or milling machine. Chemical: Heavy metals from the grinder, rust in machines. Biological: contamination by bacteria from water source, worker, and environment |

Absence of rust and corrosion Heavy metal content should be max 40 mg/kg Absence of microorganisms responsible of bio contaminations |

Frequent control of rust and corrosion Heavy metal control test Regular microbiological analysis |

Frequent cleaning and maintain ace of the grinder. Maintenance should be done regularly, Control of water source, proper, and regular cleaning of machine |

| Filtration | Biological: microbial contamination of milk by the fine cloth, containers, work environment, and workers | Maximum Total Mesophilic Aerobic Bacteria (TMAB) count of 5.47 log Colony Forming Unit (CFU)/g | Regular microbiological analysis | Disinfect, and clean all equipment, wash hands, and use gloves |

| Cooking | Biological: survival of spores, and resistant thermophilic microflora, contamination by utensils Chemical: anti-nutritional factors |

Absence of spores and microorganisms. Absence of antinutrients. |

Control the presence of bubbles in soymilk. Determine the quantity of antinutrients still present. |

Allow to boil till 100 °C check the temperature, and control the duration of treatment. Verify the state of cleanliness of utensils. Use appropriate boiling and or cooking time and temperature. |

| Coagulation | Chemical: Improper coagulation may lead to less effective syneresis, inhibition of the activity of coagulant by ineffective temperature of soymilk, and coagulation time. |

Optimum coagulation conditions should be attained | Test on protein content in whey, visually to make sure coagulation is complete. | Prior determination of quantity of coagulant with respect to the volume of milk used Check the temperature, and time of coagulation. Visual control. |

| Pressing | Biological: Recontamination by microorganisms from fine cloth, mold, insects, domestic animals, workers | Absence of microorganisms responsible of bio contaminations | Regular microbiological analysis | Clean molds, fine cloth , and other materials used wash hands, and use gloves |

| Slicing or cutting | Biological: Cross contamination by working tools, knife, slicing board, workers Physical: Stones, sand, dirt, dust, and dead insects |

Absence of microorganisms responsible of bio contaminations. Absence of stones, sand, dirt, death insects. |

Regular microbiological analysis | Proper cleaning of slicing equipment (slicing board, knife, tray), wash hands, and use gloves, hygiene of workers. |

| Frying | Chemical: Presence of products of oxidation in oil | Cooking oil should not be used more than two times to avoid poisonous products involved in lipid oxidation. Internal temperature of at least 85 °C must be attained as internal temperature of product |

Test for the presence of primary, and secondary products of oxidation | Determine the internal temperature of product, and the time |

| Stewing | Physical: Stones, sand, dirt, dust, and dead insects Biological: Contamination by bacteria , and fungi from spices |

Absence of stones, sand, dirt, death insects Absence of microorganisms responsible of bio contaminations |

Visual control Regular microbiological analysis |

Proper cleaning of ingredients before use |

| Putting on skewers | Physical: dust, dirt crumbling of slices Biological: Recontamination of soy cheese by bacteria from hands, container, and skewers |

Absence of stones, sand, dirt, Absence of microorganisms responsible of bio contaminations |

Visual control Regular microbiological analysis |

Avoid crumbling, and mechanical choc, handle with care Sterilize skewers, clean equipment, wear gloves Respect personal hygiene. |

| Storage | Physical: Stones, sand, dirt, dust, and dead insects Biological: Recontamination by microorganism from storage container Chemical: development of rancidity |

Absence of stones, sand, dirt Absence of microorganisms responsible of bio contaminations |

Visual control Using clean containers only, and storing properly at room temperature or in cool dry environment |

Close container to avoid the introduction of physical contaminants Store in clean containers placed in a clean environment |

-Identification of CCPs

Once analysis of hazards fulfilled at every production step, the identification of CCPs was followed based on the decision tree during soy cheese skewer production process. From the hazard analysis at each production process, two stages were identified as CCPs, whereas all the others were control points. These stages ought to be controlled with focus on microbial hazards only by the determination of critical limits. The identified CCPs were: stewing and packaging on skewers. The critical limit for biological hazard evaluated the content in bacteria (TMAB, total coliform, Staphylococcus spp., and Salmonella spp.), and fungi (yeast and mold) in slurry soymilk, fresh soy cheese, stewed soy cheese, and soy cheese skewer.

Microbial analysis of intermediate products

The microbiological quality of samples at different production steps in soy cheese skewer processing is exhibited in Table 3. It reveals the presence of different microorganisms with counts which were significantly different (p<0.05) from one production step to another and from one producer to the other. It was noticed that only producer five had appropriate counts in all identified microorganisms.

Once analysis of hazards fulfilled at every production step, the identification of CCPs was followed based on the decision tree during soy cheese skewer production process. From the hazard analysis at each production process, two stages were identified as CCPs, whereas all the others were control points. These stages ought to be controlled with focus on microbial hazards only by the determination of critical limits. The identified CCPs were: stewing and packaging on skewers. The critical limit for biological hazard evaluated the content in bacteria (TMAB, total coliform, Staphylococcus spp., and Salmonella spp.), and fungi (yeast and mold) in slurry soymilk, fresh soy cheese, stewed soy cheese, and soy cheese skewer.

Microbial analysis of intermediate products

The microbiological quality of samples at different production steps in soy cheese skewer processing is exhibited in Table 3. It reveals the presence of different microorganisms with counts which were significantly different (p<0.05) from one production step to another and from one producer to the other. It was noticed that only producer five had appropriate counts in all identified microorganisms.

Table 3: Mean microbial loads (Log Colony Forming Unit (CFU)/g) of intermediate products, and soy cheese skewer during production

| Producers | Steps | TMAB (<5.47 log CFU/g)* |

Yeast and mold (<2 log CFU/g)* |

Total coliforms (<2 log CFU/g)* |

Staphylococcus spp. (<2 log CFU/g)* |

Salmonella spp. (Absent)* |

| 1 | S | 6.46±0.30 bAB | 4.92±0,14 abB | 3.06±0.02 bA | 0.00±0.00 Aa | + |

| SM | 6.64±0.19 bA | 5.08±0.07 bA | 3.32±0.05 cA | 0.00±0.00 aA | + | |

| FSC | 5.35±0.21 aC | 4.15±0.21 aC | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSC | 5.20±0.03 aC | 4.42±0.59 abB | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSCS | 6.62±0.21 bD | 6.53±0.08 cC | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| 2 | S | 6.32±0.11 bcA | 5.17±0.10 bC | 3.87±0.07 bB | 0.00±0.00 aA | ND |

| SM | 6.96±0.03 dA | 5.52±0.05 bcB | 4.09±0.00 cB | 3.82±0.04 bC | ND | |

| FSC | 5.76±0.19 aB | 4.39±0.09 aC | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSC | 5.96±0.02 abD | 5.75±0.11 cD | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSCS | 6.60±0.00 cdD | 6.15±0.21 dC | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| 3 | S | 6.75±0.00 bBC | 5.68±0.00 cD | 5.35±0.05 bD | 3.58±0,15 bB | + |

| SM | 6.83±0.02 bAB | 6.18±0.00 dC | 5.73±0.08 cE | 5.08±0.05 cD | + | |

| FSC | 4.47±0.14 aB | 3.65±0.00 aB | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSC | 4.42±0.00 aB | 3.69±0.06 aB | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSCS | 4.82±0.49 aA | 4.67±0.10 bA | 0.00±0.00 aA | 3.64±0.07 bB | ND | |

| 4 | S | 6.98±0.01 cC | 5.60±0.03 cD | 3.73±0.02 bB | 3.54±0.01 bE | + |

| SM | 7.03±0.03 dB | 6.12±0.00 dC | 5.05±0.01 cC | 4.42±0.19 cE | + | |

| FSC | 0.00±0.00 aA | 0.00±0.00 aA | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSC | 0.00±0.00 aA | 0.00±0.00 aA | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSCS | 5.41±0.02 bB | 4.61±0.16 bA | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| 5 | S | 6.86±0.01 cC | 5.69±0.06 bcD | 4.50±0.12 bC | 3.77±0.10 cC | + |

| SM | 6.96±0.01 bB | 6.46±0.02 cD | 5.03±0.05 cC | 2.07±0.10 bB | + | |

| FSC | 5.76±0.01 aD | 5.04±0.20 abD | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSC | 5.83±0.01 aD | 4.42±0.59 aB | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSCS | 6.20±0.17 bCD | 5.24±0.05 bB | 0.00±0.00 aA | 5.28±0.04 dA | + | |

| 6 | S | 6.76±0.06 cBC | 4.57 ± 0.04 bA | 3.87±0.10 bB | 4.94±0.05 bF | + |

| SM | 7.25±0.10 dC | 5.06±0.04 cA | 5.23±0.04 cD | 5.38±0.11 cE | + | |

| FSC | 4.28±0.02 aB | 4.38±0.12 abC | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSC | 4.35±0.17 aB | 4.05±0.11 aB | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSCS | 5.45±0.01 bB | 4.5±0.28 bA | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| 7 | S | 7.87±0.05 dD | 6.87±0.10 cE | 5.28±0.11 bD | 4.07±0.05 bD | + |

| SM | 7.75±0.1 dD | 7.45±0.01 dE | 5.82±0.07 cE | 6.26±0.08 dF | + | |

| FSC | 6.75±0.02 cE | 6.66±0.26 cE | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSC | 5.38±0.12 aC | 5.15±0.21 aD | 0.00±0.00 aA | 0.00±0.00 aA | ND | |

| SSCS | 6.03±0.05 bC | 5.61±0.16 bB | 0.00±0.00 aA | 5.99±0.03 cA | ND |

values with the same small letter within a group are not significantly different, and values with the same capital letter between different groups are not significantly different (p>0.05) according to Duncan multiple range test with One-way ANOVA.

TMAB=Total Mesophilic Aerobic Bacteria; S=slurry; SM=soymilk; FSC=fresh soy cheese; SSC= stewed soy cheese; SSCS=soy cheese skewer; ND=not detected; +=present.

Obtained slurry after grinding contained TMAB counts of 6.32±0.11-7.87±0.05 log CFU/g; yeast and mold counts of 4.57±0.04-6.87±0.1 log CFU/g; Staphylococcus spp. counts of 0-4.94±0.05 log CFU/g, and total coliform counts of 3.06±0.02 to 5.35±0.05 log CFU/g. About 85% slurry contained Salmonella spp.

After adding excess water for homogenization and filtration, the soymilk obtained had average counts in TMAB, yeast and mold, Staphylococcus spp., and total coliforms ranging from 6.64±0.19 to 7.75±0.1 log CFU/g, 5.06±0.04 to 7.45±0.01 log CFU/g, 0 to 6.26±0.08 log CFU/g, and 3.32±0.05 to 5.82±0.07 log CFU/g, respectively. Moreover, about 86% of soymilk samples contained Salmonella spp. After heating soymilk, coagulating, and followed pressing, a rise is given to fresh pressed soy-cheese. The values in counts of fresh pressed soy-cheese for different microorganisms significantly (p<0.05) reduced as compared to soymilk. The average counts in TMAB, yeast and mold were from 0 to 6.75±0.02 log CFU/g, and 0 to 6.66±0.1 log CFU/g, respectively. Staphylococcus spp., total coliform, and Salmonella spp. were absent.

Frying and seasoning of fresh pressed soy cheese gave rise to stewed soy cheese. The analysed samples manifested average counts ranging between 0 and 5.96±0.02 log CFU/g, 0 and 5.75±0.11 log CFU/g for TMAB, yeast and mold counts, respectively. No Staphylococcus spp, total coliform, and Salmonella spp were present in stewed soy cheese. The next step involved putting stewed soy cheese on skewers to form soy cheese skewers, which were then taken to the market for sale. Samples analysis revealed that all samples had high counts in TMAB ranging from 4.42±0.01 to 6.62±0.21 log CFU/g; yeast, and mold between 4.5±0.28 and 6.53±0.08 log CFU/g.

Figure 2 uncovers the evolution of average count in all the bacteria and fungi evaluated on different samples at different processing steps. The mean average counts of all microorganisms increased from slurry to soymilk, and significantly dropped in fresh soy cheese, and stewed soy cheese until zero for some microorganisms (Staphylococcus and total coliform), then significantly increased in soy cheese skewers. Highest microbial counts were found in soymilk and the lowest in stewed soy cheese. TMAB, yeast and mold varying from 4.45 to 7.06 log CFU/g and 3.92 to 5.50 log CFU/g, respectively with the highest counts in soymilk, and the lowest in stewed soy cheese. Total coliforms and Salmonella spp. were present in slurry, and soymilk only, and absent in fresh soy cheeseand soy cheese skewers. Mean Staphylococcus spp. counts were present in slurry, soymilk, and soy cheese and skewers while they were absent in fresh soy cheese, and stewed soy cheese.

After adding excess water for homogenization and filtration, the soymilk obtained had average counts in TMAB, yeast and mold, Staphylococcus spp., and total coliforms ranging from 6.64±0.19 to 7.75±0.1 log CFU/g, 5.06±0.04 to 7.45±0.01 log CFU/g, 0 to 6.26±0.08 log CFU/g, and 3.32±0.05 to 5.82±0.07 log CFU/g, respectively. Moreover, about 86% of soymilk samples contained Salmonella spp. After heating soymilk, coagulating, and followed pressing, a rise is given to fresh pressed soy-cheese. The values in counts of fresh pressed soy-cheese for different microorganisms significantly (p<0.05) reduced as compared to soymilk. The average counts in TMAB, yeast and mold were from 0 to 6.75±0.02 log CFU/g, and 0 to 6.66±0.1 log CFU/g, respectively. Staphylococcus spp., total coliform, and Salmonella spp. were absent.

Frying and seasoning of fresh pressed soy cheese gave rise to stewed soy cheese. The analysed samples manifested average counts ranging between 0 and 5.96±0.02 log CFU/g, 0 and 5.75±0.11 log CFU/g for TMAB, yeast and mold counts, respectively. No Staphylococcus spp, total coliform, and Salmonella spp were present in stewed soy cheese. The next step involved putting stewed soy cheese on skewers to form soy cheese skewers, which were then taken to the market for sale. Samples analysis revealed that all samples had high counts in TMAB ranging from 4.42±0.01 to 6.62±0.21 log CFU/g; yeast, and mold between 4.5±0.28 and 6.53±0.08 log CFU/g.

Figure 2 uncovers the evolution of average count in all the bacteria and fungi evaluated on different samples at different processing steps. The mean average counts of all microorganisms increased from slurry to soymilk, and significantly dropped in fresh soy cheese, and stewed soy cheese until zero for some microorganisms (Staphylococcus and total coliform), then significantly increased in soy cheese skewers. Highest microbial counts were found in soymilk and the lowest in stewed soy cheese. TMAB, yeast and mold varying from 4.45 to 7.06 log CFU/g and 3.92 to 5.50 log CFU/g, respectively with the highest counts in soymilk, and the lowest in stewed soy cheese. Total coliforms and Salmonella spp. were present in slurry, and soymilk only, and absent in fresh soy cheeseand soy cheese skewers. Mean Staphylococcus spp. counts were present in slurry, soymilk, and soy cheese and skewers while they were absent in fresh soy cheese, and stewed soy cheese.

Figure 2: Change in mean microbial load counts during soy cheese skewer production process

CFU=Colony Forming Units;TMAB=Total Mesophilic Aerobic Bacteria;S=slurry; SM=soymilk; FSC=fresh soy cheese; SSC=stewed soy cheese; SSCS=soy cheese skewer

Discussion

In this study, the microbiological quality of soy cheese skewer samples sold in local markets was evaluated. All the samples collected from the markets had TMAB counts varying from 4.87±0.88 to 7.79±0.1 log CFU/g. The highest count was observed in samples from Mbouda (7.79±0.1 log CFU/g), and the lowest from Bafoussam (4.87±0.88 log CFU/g). The TMAB of about 86% of the samples was higher than 5.47 log CFU/g, which is the recommended value by the European Commission regulation concerning street foods for human consumption (EC, 2005). These results are greater than those obtained by Bolaji and Ekaete (2016) on soy wara (4.9-5.4 log CFU/g), a meat analogue made from soybean and consumed as street food in Nigeria. Moreover, Abd El-Razik et al. (2016) and Bolaji and Ekaete (2016) had identical results with street-vended soy wara in Nigeria and Egyptian Kish, a traditional fermented cereal milk mixture, respectively. The TMAB count usually presents a general view of the degree of bio contamination of a food and no further information on the various groups of available microorganisms. High levels of TMAB load in soy cheese skewers found in the markets can indicate poor hygienic conditions during production, storage, transportation, and even distribution (Zhang et al., 2020). Soy cheese is determined as a good medium for microbial growth, and high counts will considerably reduce the shelf-life of this product and intensify the risk of food-borne diseases (Rossi et al., 2016).

Yeast and mold were found in all examined samples, ranging from 2.84 to 5.91 log CFU/g, exceeding the norms of <2 log CFU/g of the European Commission (EC, 2005). This case is comparable to those of Bolaji and Ekaete (2016) (3.6-4.3 log CFU/g) on soy wara sold in the streets of Abuja in Nigeria, and Zokou et al. (2022), who demonstrated similar results in all samples of egusi pudding, a traditional food sold in the streets of Yaounde in Cameroon. Yeast and mold may constitute the natural flora in some grains, and will persist throughout processing of food, resist heat treatment, and end up in the final product, producing, in some cases, aflatoxins, which are hazardous for human health (Fasoyiro et al., 2010).

Total coliform counts ranged from 0 to 4.84 log CFU/g, with 27% of the samples at levels above the established limit of 2 Log CFU/g. Fasoyiro et al. (2010) and Ossai (2012) reported the presence of coliforms in locally processed soy cheese in Nigeria and street-vended foods in Delta State, Nigeria, at levels exceeding the recommended levels (100 CFU/g), respectively. Their availability in food may be an indicator of poor hygiene and cross-contamination during production, storage, and distribution, which could result in contamination by faeces (faecal pollution). Therefore, consumers may be exposed to intestinal disorders leading to other food-borne diseases (Abakari et al., 2018; Fasoyiro et al., 2010). Their lack in about 73% of samples may be due to the heat treatment (85-95 °C for about 30 min) applied during processing (Zokou et al., 2022).

Staphylococcus spp. in 59% of collected samples was beyond the recommended limits of <2 log CFU/g fixed by the European Commission (EC, 2005). Salamandane et al. (2021) reported the presence of Staphylococcus spp. in several RTE foods in Maputo city at unsatisfactory levels. Daniyan et al. (2011) and Ribeiro et al. (2017) demonstrated identical results with soy cheese in Nigeria and tofu sold in supermarkets in Porto Alegre, Brazil, respectively. Staphylococcus spp. are considered as Gram-negative bacteria generally found on the skin, nasal passage, and saliva, making them the most prevalent pathogen present in foods that are handled with bare hands (ISO, 2021). This could be connected to poor hygiene during production, inadequate storage conditions, and the distribution of food product. Consumption of food contaminated with Staphylococcus spp. may lead to food poisoning (Ananchaipattana et al., 2012).

Salmonella is considered as a Gram-negative bacteria responsible for illnesses including septicaemia, typhoid fever, and gastroenteritis in humans. The reason why food for consumption should be normally free of Salmonella spp., since it can cause food-borne diseases with symptoms like diarrhea, abdominal pains, nausea, headache as well as vomiting (Fasoyiro et al., 2010; Mugampoza et al., 2013). Collected and analysed samples revealed that. Salmonella spp. was absent in all the samples, not considering the seller. Aluko et al. (2014); Mugampoza et al. (2013); Nyenje et al. (2012) reported similar results for street vended foods in Nigeria, Uganda, and South Africa, respectively.

The different samples collected at different intermediate steps had counts of TMAB, yeast and mold independently of the processing step and the producer. With respect to production steps, the most contaminated samples were the slurry and soymilk. The TMAB count of the slurry varied from 6.32 to 7.87 log CFU/g, and consisted mainly of coliforms (3.06-5.35 log CFU/g) and Staphylococcus spp. (0-4.94 log CFU/g). In addition, yeast and mold were detected (4.57-5.69 log CFU/g). The high counts in slurry could be linked to the grinding machine utilized for milling, which is not always well cleaned before use. Unfortunately, none of the milling machines were thoroughly cleaned by users during observations. Furthermore, soybean grains could have been contaminated during their storage prior to being applied in the production process or on farms during harvesting and handling. These remarks are in line with those of Danbaba et al. (2014), who made the same observation during milling in the process of producing soy-kununzaki, a traditional cereal-based fermented beverage in Nigeria.

The microbial load in soymilk was significantly higher than that of slurry. The counts in TMAB, Staphylococcus, total coliform, and fungal varied from 6.64 to 7.76, 0 to 6.26, 3.32 to 5.82, and 5.08 to 7.45 log CFU/g, respectively. This could be linked to the quality of water added to the slurry for homogenization and filtration. In fact, it was observed that the water used during production came from taps, wells, and rainfall. Water can be an agent of water-borne diseases and should therefore be controlled before use, without determining the source (FAO and WHO, 2019). Fasoyiro et al. (2010) reported that 95% of analysed soy cheese used water from wells for their production, which was highly susceptible to contamination linked to poor handling. Further, the use of a fine cloth for filtration could be a reason for the increase in microbial count. The clothing might not have been cleaned properly prior to use.

Freshly pressed soy cheese demonstrated a significant decrease (p<0.05) in counts of all evaluated bacteria and fungi. A similar report was made by Rai et al. (2014) during the production of Kinema, a soybean fermented product, and Salamandane et al. (2021) on different hot street foods sold in Maputo city. These variations were observed after cooking, coagulation, and slicing by all the producers. This could manifest the effect of heat during food production (Benassi et al., 2011). Indeed, heat treatments applied to the product could have an effect on the reduction of the number of non-sporulated bacteria initially present in food (Ashenafi, 2012). The fact that several samples still contained a number of TMAB may imply that cooking temperatures were not favourable enough to reduce or eliminate completely the microbial load or simply due to the formation of spores due to insufficient heat. This could also be related to contamination by the slicing board, the knife, or regular hand contact with the fresh soy cheese (Sapieja, 2017).

Stewed soy cheese had a significantly low (p<0.05) microbial load as compared to soymilk. Only about 42% had TMAB counts at acceptable levels. About 40% of the samples had Staphylococcus spp. Only 14% contained Salmonella spp. and total coliform was absent in all samples. The heat treatment applied during frying and cooking soy cheese was able to reduce the microbial load by destroying some microorganisms previously present. This product undergoes three different thermal processes: boiling-coagulation of soymilk, which significantly decreases counts of microorganisms related to the raw material; frying; and finally stewing for seasoning, during which a third heat treatment is applied (Sogin et al., 2021). Additionally, this could be related to the use of spices and herbs for seasoning. Many studies have illustrated that spices possess antimicrobial effects (Haute et al., 2016; Liu et al., 2017; Wu et al., 2023) This is the case with Wu et al. (2023), who revealed that after marinating leisurely dried tofu with about twenty different spices and herbs, the total viable counts significantly decreased. Since fresh soy cheese and stewed soy cheese had significantly low counts in different microflora, the high counts of the slurry, and soymilk seem not to have any significant effect on the microbiological quality of the soy cheese.

Stewed soy cheese slices were then cooled and packaged by putting them on skewers. There was a significant increase in bacteria and fungi count in processed, RTE soy cheese packaged on skewers. This was probably due to further re-contamination during the cooling process and frequent hand contact during packaging, which indicates poor hygiene during post-production processes (Zokou et al., 2022). In fact, after frying and stewing, the slices are permitted to cool, and further placed on skewers previously prepared by the producers or bought from the markets using hands, which are sometimes either not washed or poorly washed, causing contamination (Kothe et al., 2016; Monney et al., 2014). Moreover, during storage, transportation, negotiations with customers who may end up not taking the piece touched before, persons, their clothes, and other individuals. Cross-contamination by domestic animals, flies, and insects may also be linked to poor microbial quality (Bolaji and Ekaete, 2016; Kothe et al., 2016). Healthy or sick, human beings naturally possess a good number of bacteria on the skin, digestive, and respiratory tracts; coughing, sneezing, and sweating can favour the transmission of germs to foodstuffs (Salamandane et al., 2021). The places where the food is commercialised could also be a source of contamination. The markets which are generally populated, dusty, and contaminated with flies everywhere could be carriers of faecal contamination (Bolaji and Ekaete, 2016).

A CCP is a step in the process of production where control measures should be applied to prohibit, reduce, and/or eliminate hazards to an acceptable level (Ackah et al., 2018; CAC, 2009). Once the CCPs determined, critical limits, monitoring procedures, and control measures where set. Monitoring procedures involves the act of conducting a planned sequence of observations or measurement of control parameters to assess whether a CCP is under control. It involves all actions taken to detect the presence or absence of a particular danger at processing steps in order to determine if the critical limits of a CCP is being met. Control measures are any actions and activities that can be used to prevent or eliminate a food safety hazard or decrease it to an acceptable level (CAC, 2009).

The flowchart generally used by producers during processing and the production conditions was applied to determine the CCPs. The production conditions varied from one producer to the next, but the main steps remain the same. These steps included soaking of grains, draining, grinding, homogenization, filtrating, cooking, coagulation, pressing, slicing, frying, stewing, as well as packaging. From these operational units, CCPs were identified according to microbiological hazards. Arshad and Zahoor (2019) and Loukieh et al. (2018) explained that many developing countries still use local habits in the preparation of different foods meant for sale to the general public. The first CCP, stewing, is the last step involving heat treatment. It is a method of cooking that implies cooking just below the boiling point at temperatures that can rise up to 90 °C for a long period of time. Appropriate heating conditions (temperature and time) will reduce the microbial load (Moelyaningrum, 2019). The second CCP was the packaging of the final product on skewers with bare hands for sale. The stewed soy cheese was demonstrated in opened trays, facilitating contact with dirt, dust, flies, and domestic animals. The slices were picked up with hands, and three to four different slices of stewed soy cheese were placed on skewers for sale. The skewers could harbour bacteria and be a source of microbial contamination. During packaging, the personal hygiene of workers and the used tools should be ensured to restrict direct contact with food (Fasoyiro et al., 2010). This involves the use of gloves, headgear, face masks, and proper cleaning of tools as well as equipment. The cleanliness of the packaging environment should also be assured in order to avoid or limits unnecessary contaminations (Bonne, 2013). These stages should be well controlled to limit contamination to unsatisfactory levels (Fasoyiro et al., 2010).

A summary of the microbiological quality of intermediate samples during the processing of stewed soy cheese betrays that the most contaminated intermediary product was slurry, followed by soymilk, and finally soy cheese skewers in all examined microorganisms. While fresh and stewed soy cheese were the least contaminated of all the microorganisms, Salmonella spp. was present only in slurry and soymilk and completely absent in fresh and stewed soy cheese, and soy cheese skewers. Normally, food for consumption should be void of Salmonella spp., as it is capable of causing food-borne diseases like typhoid fever (Fasoyiro et al., 2010; Mugampoza et al., 2013).

Conclusion

This study identified the interest in safety of soy cheese skewers consumed in the street, and the production process in some cities in the west region of Cameroon. The results of the microbiological quality of soy cheese skewers sold in some streets in the West region, and the determination of CCPs during the production process highlight the poor microbiological quality of this product and the inadequate sanitary practices during soy cheese skewer processing. The identified microorganisms from commercial samples were total mesophilic aerobic flora, Staphylococcus spp., total coliforms, yeast and mold , implying poor sanitary conditions either during processing, storage or distribution. Salmonella spp. which was completely absent in these commercial food. The HACCP systems revealed that stewing and packaging on skewers were the main CCPs with respect to microbiological hazards. Therefore, precautions should be taken during the soy cheese skewer production process at these steps to reduce or limit contamination. The ingredients, tools, equipment should be cleaned properly before used. Those handling the production should also preserve an appropriate personal hygiene to avoid self-contaminations. Regular controls should be performed by the government to ensure quality products. These measures may assist both producers and vendors in presenting available good quality products to consumers.

Author contributions

E.N.S., B.T., R.Z., J.M.K., and M.H.W. designed the study, carried experimental work, collected samples, and collected data; E.N.S., B.T., R.Z., F.D.T., S.H.N., G.B.T., C.T.T., A.H.F.K., J.M.K. analysed the data; E.N.S., B.T., R.Z., C.T.T., A.H.F.K., G.B.T., S.H.N., F.D.T., J.M.K., M.H.W. wrote the manuscript. All authors read and approved the final manuscript.

Funding

This research did not receive any grant from funding agencies in the public, commercial, or not-for-profit sectors. This research was jointly financed by authors.

Acknowledgments

The authors are grateful to sellers and producers of soy cheese skewers in the west region of Cameroon for their cooperation; authors would like to thank the head of the Research Unit of Biochemistry of Medicinal Plants, Food Sciences, and Nutrition (URBPMAN), Department of Biochemistry, University of Dschang-Cameroon, where the research work was carried

Conflicts of interest

The authors declare no conflict of interest.

Ethical consideration

Not applicable.

References

Abakari G., Cobbina S.J., Yeleliere E. (2018). Microbial quality of ready to-eat vegetable salads vended in the central business district of Tamale, Ghana. International Journal of Food Contamination. 5: 1-9. [DOI: 10.1186/s40550-018-0065-2]

Abd El-Razik M.M., Hassan F.Y.M., Gadallah G.E.M. (2016). Implementation of HACCP plan for the production of Egyptian kishk (a traditional fermented cereal-milk mixture). Food, and Nutrition Sciences. 7: 1262-1275. [DOI: 10.4236/fns.2016. 713116]

Ackah N.B., Baidoo E.A., Kwadwo Appiah A.H.K. (2018). Validating a HACCP system for the production of vegetable shito. Journal of Food Quality. 2018: 1-7. [DOI: 10.1155/2018/7146040]

Aluko O.O., Ojeremi T.T., Olaleke D.A., Ajidagba E.B. (2014). Evaluation of food safety and sanitary practices among food vendors at car parks in Ile Ife, southwestern Nigeria. Food Control. 40: 165-171. [DOI: 10.1016/j.foodcont.2013.11.049]

Ananchaipattana C., Hosotani Y., Kawasaki S., Pongswat S., LatiFul B., IsoBe S., Inatsu Y. (2012). Bacterial contamination of soybean curd (tofu) sold in Thailand. Food Science and Technology Research. 18: 843-848. [DOI: 10.3136/fstr.18.843]

Anirban D., Rasane P., Sawinder K., Jyoti S., Luwang M.D. (2017). Tofu: technological, and nutritional potential. Indian Food Industry Magazine. 36: 8-24

Arshad F., Zahoor T. (2019). Assessing the microbiological safety status of most commonly consumed food items sold at local, and branded restaurants of Faisalabad, Pakistan. Journal of Food Safety. 39: e12587. [DOI: 10.1111/jfs.12587]

Ashenafi M. (2012). Thermal effects in food microbiology. In: Sun D.-W. (Editor). Thermal food processing: new technologies, and quality issues. 2nd edition. CRC press, Boca Raton. pp: 65-79. [DOI: 10.1201/b12112-5]

Benassi V.T., Yamashita F., Prudencio S.H. (2011). A statistical approach to define some tofu processing conditions. Food Science and Technology. 31: 897-904. [DOI: 10.1590/S0101-20612011000400011]

Bolaji O.A., Ekaete A.U. (2016). Safety of street-vended soy wara in Nigeria. Journal of Food Protection. 79: 169-173. [DOI: 10.4315/0362-028X.JFP-15-136]

Bonne R. (2013). Presentation of two original methods to facilitate in the IAA implementation of best practices, and hygiene manufacturing, and method of HACCP, as defned by the

codex alimentarius. Paul Sabatier University, PhD Thesis. France, Toulouse. URL: http://thesesups.ups-tlse.fr/2161/1/ 2013TOU30238.pdf.

Codex Alimentarius Commission (CAC). (2009). Food hygiene: basic texts. 4th edition. Joint FAO/WHO Food Standards Programme, Rome, Italy. URL: https://www.fao.org/3/a1552e/a1552e00.pdf.

Danbaba N., Oyeleke S.B., MajiAlhassan T., Kolo I.N.-U., Hauwawu H., Kolo I.F. (2014). Hazard analysis critical control points (HACCP) in the production of soy-kununzaki: a traditional cereal based fermented beverage of Nigeria. American Journal of Food Science and Technology. 2: 196-202. [DOI: 10.12691/ajfst-2-6-5]

Daniyan S.Y., Abalaka M.E., Momoh J.A., Adabara N.U. (2011). Microbiological, and physiochemical assessment of street vended soyabean cheese sold in Minna, Nigeria. International Journal of Biomedical, and Advance Research. 2: 25-31. [DOI: 10.7439/ijbar.v2i1.19]

Edima H.C., Tem Nnam R.K., Awono Enama T., Biloa D.M., Ndjouenkeu R. (2014). Case study of the street food sector in the metropolitan areas of a Cameroonian city, Yaounde. International Journal of Current Microbiology and Applied Science. 3: 740-751.

European Communities (EC). (2005). European Commission Regulation (EC) No 2073/2005 of 15 November 2005 on microbiological criteria for foodstuffs. Official Journal of the European :union:. L 338: 1-30. URL: https://eur-lex.europa.eu /legal-content/EN/TXT/PDF/?uri=CELEX: 02005R2073-20140601&rid=1.

FAO, WHO. (2019). Safety and quality of water used in food production and processing - meeting report. Microbiological Risk Assessment Series no. 33. Rome. URL: https://iris.who.int/bitstream/handle/10665/327724/9789241516402-eng.pdf?sequence=1.

Fasoyiro S.B., Obatolu V.A., Ashaye O.A., Adegoke G.O., Farinde E.O. (2010). Microbial hazards, and critical control points of locally processed soy-cheese in Nigeria. Nutrition and Food Science. 40: 591-597. [DOI: 10.1108/00346651011090392].

Food and Agriculture Organization of the United Nations (FAO). (2009). Good hygienic practices in the preparation and sale of street food in Africa, tools for training. FAO, Rome, Italy. URL: https://www.fao.org/3/a0740e/a0740e00.pdf.

Haute S.V., Raes K., Meeren P.V., Sampers I. (2016). The effect of cinnamon, oregano, and thyme essential oils in marinade on the microbial shelf life of fish, and meat products. Food Control. 68: 30-39. [DOI: 10.1016/j.foodcont.2016.03.025]

International Organization for Standardization (ISO) 4832:2006. (2006). Microbiology of food and animal feeding stuffs — horizontal method for the enumeration of coliforms - colony count technique. URL: https://www.iso.org/standard/38282.html.

International Organization for Standardization (ISO) 21527-1:2008. (2008). Microbiology of food and animal feeding stuffs — horizontal method for the enumeration of yeasts, and moulds. Part 1: colony count technique in products with water activity greater than 0,95. URL: https://www.iso.org/standard/ 38275.html.

International Organization for Standardization (ISO) 6579-1:2017. (2017). Microbiology of the food chain — horizontal method for the detection, enumeration, and serotyping of Salmonella. Part 1: Detection of Salmonella spp. URL: https://www.iso.org/ standard/56712.html.

International Organization for Standardization (ISO) 6888-1:2021. (2021). Microbiology of the food chain — horizontal method for the enumeration of coagulase-positive staphylococci (Staphylococcus aureusand other species). Part 1: method using baird-parker agar medium. URL: https://www.iso.org/standard/ 76672.html.

International Organization for Standardization (ISO) 4833-1:2013. (2013). Microbiology of the food chain — horizontal method for the enumeration of microorganisms. Part 1: colony count at 30 °C by the pour plate technique. URL: https://www.iso.org/ standard/53728.html.

International Organization for Standardization (ISO) 6887-1:2017. (2017). Microbiology of the food chain. Preparation of test samples, initial suspension, and decimal dilutions for microbiological examination. Part 1: general rules for the preparation of the initial suspension and decimal dilutions. URL: https://www.iso.org/standard/63335.html.

Kothe C.I., Schild C.H., Tondo E.C., Malheiros P.D.S. (2016). Microbiological contaminationand evaluation of sanitary conditions of hot dog street vendors in Southern Brazil. Food Control. 62: 346-350. [DOI: 10.1016/j.foodcont.2015.11.005]

Liu Q., Meng X., Li Y., Zhao C.-N., Tang G.-Y., Li H.-B. (2017). Antibacterial, and antifungal activities of spices. International Journal of Molecular Science. 18: 1283. [DOI: 10.3390/ ijms18061283]

Loukieh M., Mouannes E., Abou Jaoudeh C., Hanna Wakim L., Fancello F., Bou Zeidan M. (2018). Street foods in Beirut city: an assessment of the food safety practices and of the microbiological quality. Journal of Food Safety. 38: e12455. [DOI: 10.1111/jfs.12455]

Moelyaningrum A.D. (2019). Boric acid, and hazard analysis critical control point (HACCP) on kerupuk to improve the Indonesian`s traditional foods safety. International Journal of Scientific and Technology Research. 8: 50-54. [DOI: 10.31227/osf.io/grftm]

Monney I., Agyei D., Ewoenam B.S., Priscilla C., Nyaw S. (2014). Food hygiene, and safety practices among street food vendors: an assessment of compliance, institutionaland legislative framework in Ghana. Food and Public Health. 4: 306-315. [DOI: 10.5923/j.fph.20140406.08]

Mugampoza D., Byarugaba G.W.B., Nyonyintono A., Nakitto P. (2013). Occurrence of Escherichia coli and Salmonella spp. in street-vended foods and general hygienic and trading practices in Nakawa Division, Uganda. American Journal of Food and Nutrition. 3: 167-175. [DOI: 10.5251/ajfn.2013.3.3.167.175]

Nyenje M.E., Odjadjare C.E., Tanih N.F., Green E., Ndip R.N.(2012). Foodborne pathogens recovered from ready-to-eat foods from roadside cafeterias and retail outlets in Alice, eastern cape province, South Africa: public health implications. International Journal of Environmental Research, and Public Health. 9: 2608-2619. [DOI: 10.3390/ijerph9082608]

Oboh G. (2006). Coagulants modulate the hypocholesterolemic effect of tofu (coagulated soymilk). African Journal of Biotechnology. 5: 290-294. [DOI: 10.1089/jmf.2006.208]

Oluwole O.O., Prudent O.O. (2020). Evaluation of microbial and nutritonal values of commercially packaged soymilk sold in Akure, Nigeria. Journal of Nutritional Medicine and Diet Care. 6: 1-6. [DOI: 10.23937/2572-3278/1510047]

Ossai O.S. (2012). Bacteriological quality and safety of street vended foods in Delta State, Nigeria. Journal of Biology, Agriculture, and Healthcare. 2: 114-118.

Qin P., Wang T., Luo Y. (2022). A review on plant-based proteins from soybean: health benefitsand soy product development. Journal of Agriculture and Food Research. 7: 100265. [DOI: 10.1016/j.jafr.2021.100265]

Rai K.A., Dhiman N.K., Kumar N.A., Aneja A. (2014). Emerging preservation techniques for controlling spoilage and pathogenic microorganisms in fruit juices. International Journal of Microbiology. 2014: 1-14. [DOI: 10.1155/2014/758942]

Ribeiro T.T.B.C., Costa G., Da Costa M. (2017). Microbial contamination in industrial tofu. Food Technology. 47: e20160234. [DOI: 10.1590/0103-8478cr20160234]

Rossi F., Felis G., Martinelli A., Calcavecchia B., Torriani S. (2016). Microbiological characteristics of fresh tofu produced in small industrial scale and identification of specific spoiling microorganisms (SSO). LWT - Food Science and Technology. 70: 280-285. [DOI: 10.1016/j.lwt.2016.02.057]

Salamandane A., Silva A.C., Brito L., Malfeito-Ferreira M. (2021). Microbiological assessment of street foods at the point of sale in Maputo (Mozambique). Food Qualityand Safety. 5: 1-9. [DOI: 10.1093/fqsafe/fyaa030]

Sapieja A. (2017). Implementation of HACCP plan for blue-mould tofu with focus on microbial hazards. Master´s thesis.

Swedish University of Agricultural Sciences, Uppsala. URL: https://stud.epsilon.slu.se/10477/1/sapieja_a_171019.pdf.

Sogin J.H., Lopez-Velasco G., Yordem B., Lingle C.K., David J.M., Cobo M., Worobo R.W. (2021). Implementation of ATP and microbial indicator testing for hygiene monitoring in a tofu production facility improves product qualityand hygienic conditions of food contact surfaces: a case study. Applied and Environmental Microbiology. 87: e02278-20. [DOI: 10.1128/ AEM.02278-20]

Wu T., Huang Z., Zhao L., Zhou X., Chen H., Zhou X., Li M., Zhou J., Lin Y. (2023). Effects of the marinating process on the quality characteristicsand bacterial community of leisure dried tofu. Foods. 12: 841.[DOI: 10.3390/foods12040841]

Yakubu N., Amuzat A.O. (2012). Effects of different types of coagulants on the nutritional quality of tofu produced in the Northern part of Nigeria. World Journal of Dairyand Food Sciences. 7: 135-141. [DOI: 10.5829/idosi.wjdfs.2012.7.2.1106]