Volume 12, Issue 1 (March 2025)

J. Food Qual. Hazards Control 2025, 12(1): 11-26 |

Back to browse issues page

Ethics code: Not applicable.

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Fahrullah F, Kisworo D, Noersidiq A. Synthesis of Whey-Chia Seed Edible Film containing Cinnamon Essential Oil as Biodegradable Food Packaging Material. J. Food Qual. Hazards Control 2025; 12 (1) :11-26

URL: http://jfqhc.ssu.ac.ir/article-1-1258-en.html

URL: http://jfqhc.ssu.ac.ir/article-1-1258-en.html

Department of Animal Science, Faculty of Animal Science, Universitas Mataram, Jl. Majapahit 62, Mataram, NTB 83115, Indonesia , fahrullah@unram.ac.id

Full-Text [PDF 1305 kb]

(624 Downloads)

| Abstract (HTML) (765 Views)

To cite: Fahrullah F., Kisworo D., Noersidiq A. (2025). Synthesis of whey-chia seed edible film containing cinnamon essential oil as biodegradable food packaging material. Journal of Food Quality and Hazards Control. 12: 11-26.

Introduction

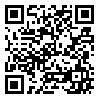

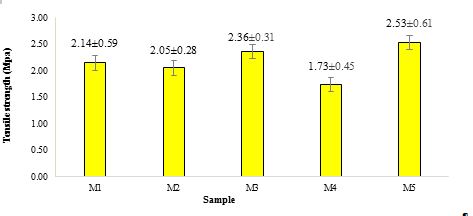

Figure 1: Tensile strength of whey-chia seed films varying cinnamon oil comcentrations

M1=0% cinnamon essential oil; M2=2% cinnamon essential oil; M3=4% cinnamon essential oil: M4=6% cinnamon essential oil; M5=8% cinnamon essential oil

Figure 2: Elongation of whey-chia seed films with varying cinnamon oil concentrations

M1=0% cinnamon essential oil; M2=2% cinnamon essential oil; M3=4% cinnamon essential oil: M4=6% cinnamon essential oil; M5=8% cinnamon essential oil

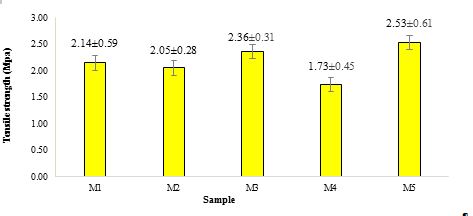

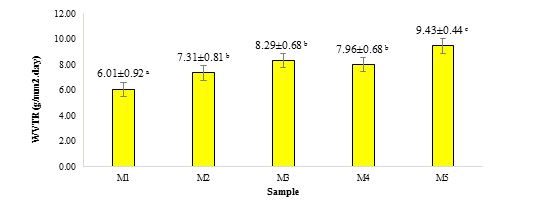

Figure 3: Water Vapor Transmission Rate (WVTR) of whey-chia seed films with varying cinnamon oil concentrations

M1=0% cinnamon essential oil; M2=2% cinnamon essential oil; M3=4% cinnamon essential oil: M4=6% cinnamon essential oil; M5=8% cinnamon essential oil

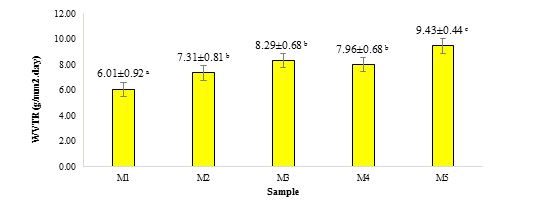

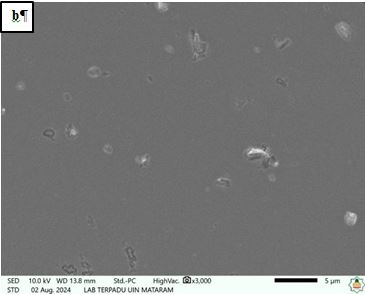

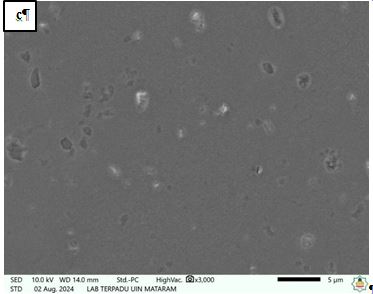

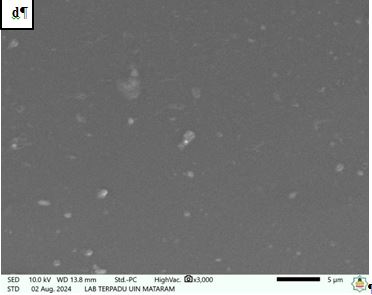

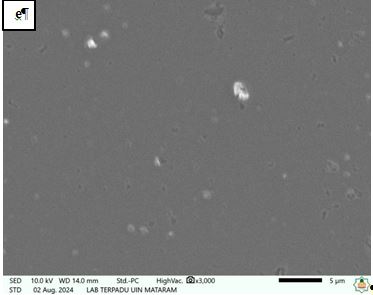

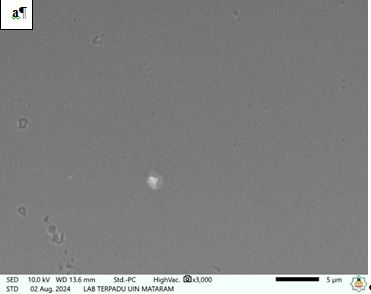

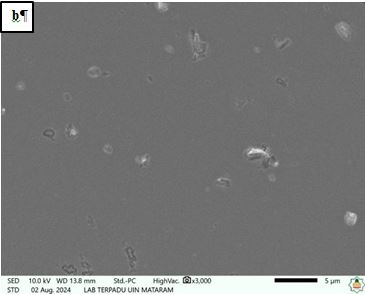

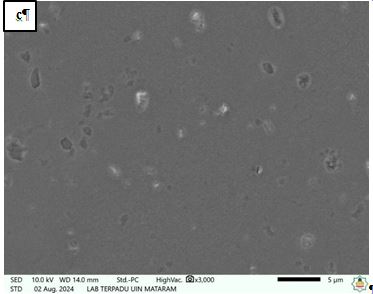

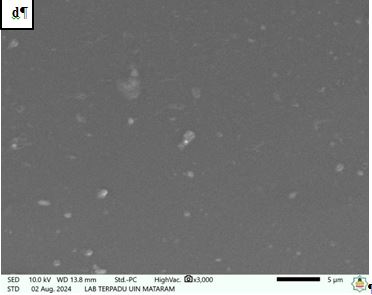

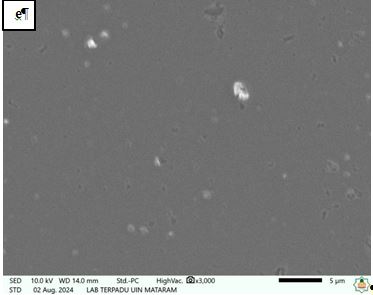

Figure 4: Microstructure of whey–chia seed film with addition of: (a) 0% cinnamon essential oil; (b) 2% cinnamon essential oil; (c) 4% cinnamon essential oil; (d) 6% cinnamon essential oil; and (e) 8% cinnamon essential oil in 3,000 times

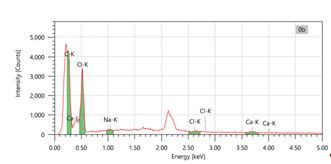

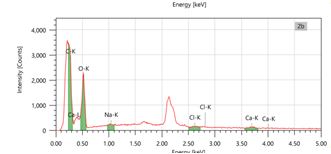

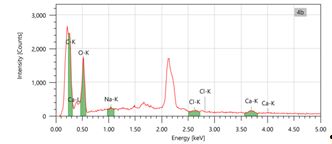

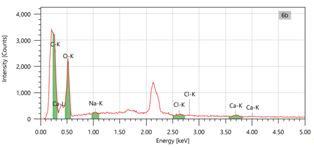

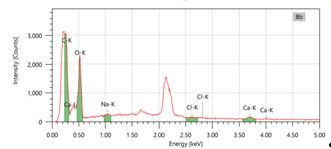

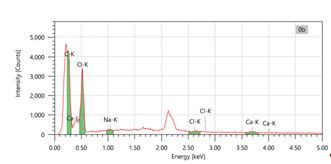

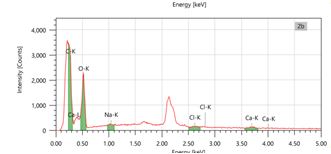

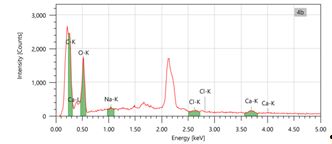

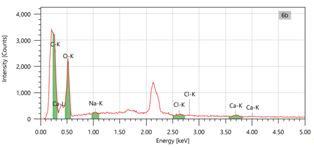

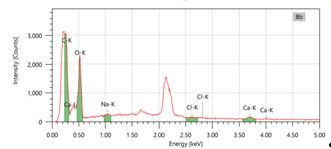

Figure 5: Energy Dispersive X-ray Spectroscopy (EDS) of whey–chia seed film with addition of: (0b) 0% cinnamon essential oil; (2b) 2% cinnamon essential oil; (4b) 4% cinnamon essential oil; (6b) 6% cinnamon essential oil; and (8b) 8% cinnamon essential oil

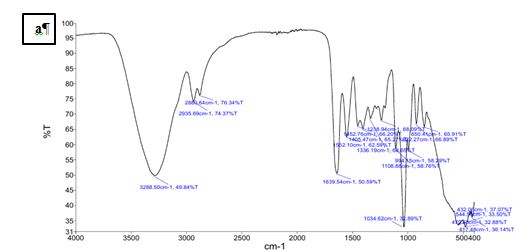

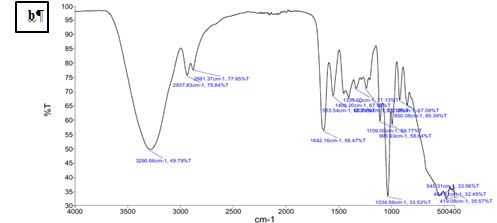

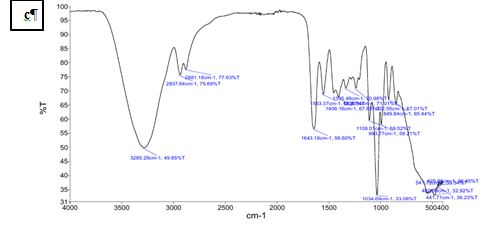

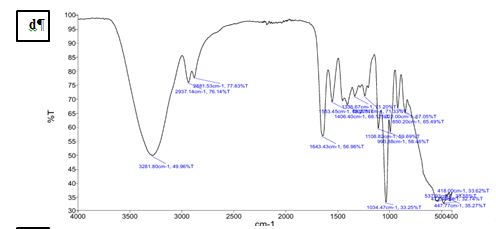

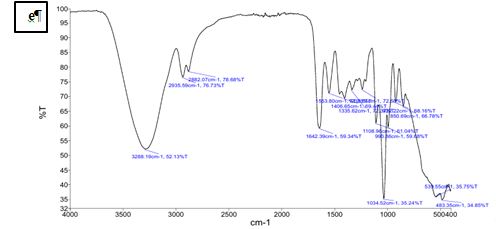

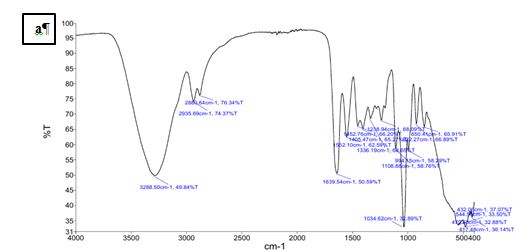

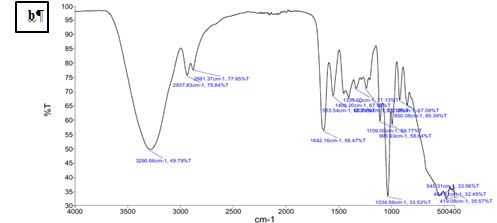

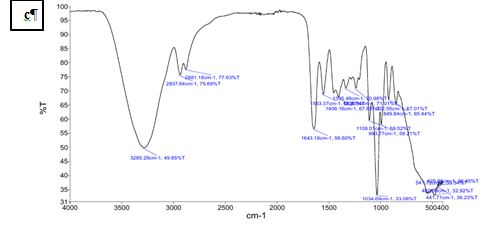

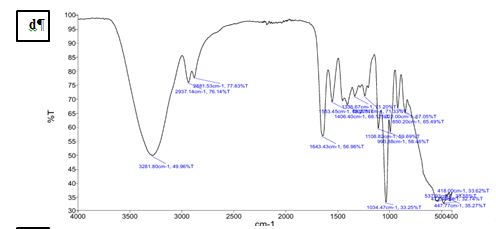

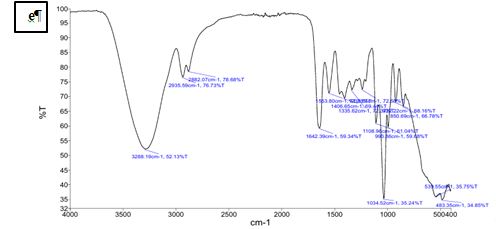

Figure 6: Fourier Transform Infrared (FTIR) of whey–chia seed film with addition of: (a) 0% cinnamon essential oil; (b) 2% cinnamon essential oil; (c) 4% cinnamon essential oil; (d) 6% cinnamon essential oil; and (e) 8% cinnamon essential oil

Table 1: The average diameter of the resistance zone (mm) of cinnamon oil againts Escherichia coli and Staphylococcus aureus

Full-Text: (267 Views)

Synthesis of Whey-Chia Seed Edible Film containing Cinnamon Essential Oil as Biodegradable Food Packaging Material

F. Fahrullah [*]* , D. Kisworo, A. Noersidiq

Department of Animal Science, Faculty of Animal Science, Universitas Mataram, Jl. Majapahit 62, Mataram, NTB 83115, Indonesia

F. Fahrullah [*]*

Department of Animal Science, Faculty of Animal Science, Universitas Mataram, Jl. Majapahit 62, Mataram, NTB 83115, Indonesia

HIGHLIGHTS

- Elongation with 0, 2, 4, 6, and 8% cinnamon essential oil addition were found to be 77.36, 74.13, 73.29, 69.00, and 64.94%, respectively.

- Cinnamon essential oil at higher levels enhances tensile strength, Water Vapor Transmission Rate, and increases C and O content.

- Cinnamon essential oil affects absorption bands of -OH and C=O groups and boosts the inhibition zone against Escherichia coli and Staphylococcus aureus.

- The film properties were found to be optimal when a concentration of 8% cinnamon essential oil was used.

| Article type Original article |

ABSTRACT Background: Edible films provide a promising alternative to plastic packaging, serving as a matrix for active compounds such as antibacterial agents and enchancing the nutritional content of the packaged product. This study aimed to determine the effect of cinnamon essential oil incorporation on the manufacture of whey-chia seed edible films. Methods: A completely randomized design was applied, testing various concentrations of cinnamon essential oil: M1 (0%), M2 (2%), M3 (4%), M4 (6%), and M5 (8%). A total of 25 samples were analyzed from June to November 2024. The study assessed physical characteristics including tensile strength, elongation, Water Vapor Transmission Rate (WVTR), microstructure, Energy-Dispersive Spectroscopy (EDS), and Fourier Transform Infrared spectroscopy (FTIR). Additionally, microbiological characteristics were evaluated, focusing on antibacterial activity against Escherichia coli and Staphylococcus aureus. Data were analyzed using Analysis of Variance and further examined through Duncan Multiple Range Test in Statistical Program for Social Science (SPSS) version 24.0. Results: The addition of cinnamon oil did not significantly affect the tensile strength and elongation of the whey-chia seed edible film (p>0.05). Tensile strength values ranged from 1.73-2.53 MPa, while elongation values ranged from 64.94-77.36%. However, cinnamon oil had a notable impact on WVTR and antibacterial activity (p<0.01). WVTR values ranged from 6.01 to 9.43 g/mm2.day, and the inhibition zones against E. coli and S. aureus ranged from 10.60 to 11.35 and 10.70 to 14.60 mm, respectively. The 8% cinnamon essential oil concentration was the most effective in improving tensile strength and antibacterial properties, making it suitable for biodegradable food packaging. EDS analysis showed increased carbon and oxygen content in the films, and FTIR indicated changes in intermolecular interactions, affecting absorption bands of functional groups like -OH and C=O. Conclusion: The treatment with the addition of 8% cinnamon oil concentration was found to be the most effective treatment. © 2025, Shahid Sadoughi University of Medical Sciences. This is an open access article under the Creative Commons Attribution 4.0 International License. |

|

| Keywords Eugenol Whey Edible Films Biodegradable Plastics Food Packaging Food Preservation. |

||

| Article history Received: 04 Sep 2024 Revised: 15 Dec 2024 Accept: 25 Feb 2025 |

||

| Abbreviations EDS=Energy Dispersive X-ray Spectroscopy FTIR=Fourier Transform Infrared SEM=Scanning Electron Microscopy WVTR=Water Vapor Transmission Rate |

To cite: Fahrullah F., Kisworo D., Noersidiq A. (2025). Synthesis of whey-chia seed edible film containing cinnamon essential oil as biodegradable food packaging material. Journal of Food Quality and Hazards Control. 12: 11-26.

Introduction

The interest in biodegradable packaging materials is determined by the necessity to reduce the use of non-degradable plastics to protect the environment. The use of synthetic packaging can have serious impacts on the environment, one of which is that this packaging waste takes a very long time to decompose, with a range of 10 to 1,000 years (De Dicastillo et al., 2016). Over the past five decades, the food industry has employed a range of synthetic plastics, giving rise to environmental concerns among consumers and stakeholders in the food production chain (Aleksanyan, 2023). Consequently, consumers are demanding a greater variety of natural foods that are free from synthetic additives. In response to this assertion, researchers have collaborated to develop biodegradable packaging solutions. This biodegradable packaging represents a potential alternative for use as a food packaging material, with the dual objective of reducing environmental damage and maintaining the shelf life, quality, and safety of the food products it covers. The growing concern for environmental and food safety has led to a heightened interest in the development of biodegradable packaging materials for use in the food industry. The issue that this research seeks to address is the pressing need for the development of environmentally friendly food packaging materials. The utilization of plastic packaging that does not undergo rapid degradation results in environmental contamination and a detrimental impact on the ecosystem. Furthermore, biodegradable food packaging offers additional benefits, including antimicrobial and antioxidant properties. This research is expected to contribute to the advancement of more sustainable packaging solutions. In this regard, one of the emerging trends in film development is the utilization of agricultural by-products and renewable natural resources as a means of replacing conventional packaging materials (Nisar et al., 2018). In recent years, edible packaging has been developed that can be manufactured from polymers such as proteins (Mouzakitis et al., 2022), carbohydrates (Shivangi et al., 2021), lipids (Yousuf et al., 2022) and composites (Fahrullah et al., 2021, 2022, 2020; Herrera-vázquez et al., 2022) in the form of edible films.

Edible films represent a promising alternative to plastic packaging, especially as biodegradable packaging materials. One of the key ingredients used in the development of these films is whey protein, which has the potential to act as a barrier to moisture, oxygen, lipids, and aroma (Schmid, 2013). However, whey protein-based films tend to have limitations in water vapor barrier properties due to their hydrophilic nature (Azevedo et al., 2015; Teixeira et al., 2014). To address this issue, one promising approach is the incorporation of polysaccharides from plant seeds that can form gels, such as chia seeds. Chia seeds are known for their functional properties, including high viscosity in water and positive metabolic effects, making them an ideal material for developing biodegradable films (Chollakup et al., 2020). Additionally, chia seed-based films possess antimicrobial properties, which can help prevent food spoilage and extend product shelf life (Beikzadeh et al., 2020).

The use of essential oils, such as cinnamon essential oil, in these films offers added potential as they have strong antimicrobial properties. The incorporation of essential oils not only enhances the barrier properties of the film but also supports the primary goal of biodegradable packaging to preserve food quality without synthetic preservatives (Zubair et al., 2022). Focusing on the development of biodegradable films using natural materials such as whey, chia, and essential oils provides an environmentally friendly solution for the food packaging industry.

Cinnamon essential oil is an essential oil that can be used to obtain good film characteristics. The incorporation of essential oils can enhance the mechanical properties of the film, thereby extending its shelf-life (Praseptiangga et al., 2021). Cinnamon contains tannins, saponins, and flavonoids that exert an antiseptic effect, damaging microbial cell membranes as a result. Previously, cinnamon essential oil has been employed for the assessment of the mechanical properties of iota-carrageenan films (Praseptiangga et al., 2021). Nevertheless, it is acknowledged that research on whey-based edible films with the addition of cinnamon remains scarce.

Materials and methods

Materials and instruments

This experiment used whey protein, chia seed (Greenara, Indonesia), glycerol (Merck, Germany), NaOH (Merck, Germany), ethanol pro analysis (Merck, Germany), cinnamon essential oil, silica gel, distilled water, label paper, aluminum foil, and clean water. The main instruments used included erlenmeyer (Pyrex, Indonesia), thermometer (Gelsonlab HSGT-067, China), magnetic stirrer, hot plate stirrer (FAITHFUL SH-2, China), desiccator, Attenuated Total Reflection-Fourier Transform Infrared (ATR-FTIR; Perkin Elmer/Spectrum Two), and Scanning Electron Microscope (SEM; JEOL JCM-7,000, Japan).

Chia seed extraction

The chia seeds were subjected to a rigorous four-stage washing process utilizing ethanol, with the objective of eliminating any extraneous materials. Subsequently, the ethanol was extracted from the seeds via filtration, followed by the evaporation of the residual solution in an oven at 70 °C. The seeds were then pulverized into smaller particles using a blender (Miyako, Indonesia). The resulting chia seed granules were then macerated in ethanol at a ratio of 1:5 and soaked for three days. Following this, the chia seed filtrate was filtered using Whatman 41 filter paper. The chia seed filtrate was then subjected to evaporation in a Heidolph Rotary Evaporators - Hei-VAP Value Digital G3 device, resulting in a chia seed solution (Khazaei et al., 2014).

Sample preparation

A total of 25 samples were analyzed from June to November 2024. The predetermined treatment was followed by combining the whey (one g) and chia seeds (one ml), which were then combined with distilled water until the final volume reached 15 ml. The resulting mixture of whey and chia seeds was combined with a 30% glycerol plasticizer and heated on a hot plate at 90±2 °C. Cinnamon essential oil was added at each concentration (0, 2, 4, 6, and 8%) according to the treatment, and the mixture was stirred using a magnetic stirrer at 250 rpm for 30 min. The solution was then neutralized with NaOH until a pH of 7–8 was reached. Subsequently, the film solution was transferred to a petri dish and heated in an oven at 50 °C for a period of two days. Moreover, the completed edible film was covered with aluminum foil before undergoing testing (Fahrullah et al., 2020).

Tensile strength

The tensile strength of the edible film was evaluated through a series of tensile tests, where in the film was cut into 8x3 cm shapes with a diameter of 1.5 cm, attached horizontally to a clamp, and subjected to a tensile force until the film exhibited visible indications of rupture (Wittaya, 2013).

Elongation

The elongation value of the edible film was evaluated utilizing a Universal Instrument Tensile Strength Meter (HongJin, China). The film was divided into 10×5 cm sections prior to being extended at a rate of 50 mm/min. The formula used for film elongation was adopted from (Wardana and Widyaningsih, 2018):

Where, L is the film length at break (mm) and L0 is the initial film length (mm).

Water Vapor Transmission Rate (WVTR)

The WVTR was measured by cutting a circular film with a diameter of 2.8 cm. The film pieces were stored in a glass containing 3 g of silica gel and put in a desiccator, and then measurements were taken every 24 h for 5 days. The WVTR was expressed in units of g/mm2.day using the formula (ASTM, 2005):

Where, n is the change of weight (g), t is time (days), and A is the surface area of the edible film (mm2).

Microstructure film

The microstructures of the edible film were examined using a SEM. The edible film, measuring 0.5×0.5 cm, was coated with carbon and gold. The prepared sample was then placed in the SEM for microstructural observation.

Energy Dispersive X-ray Spectroscopy (EDS)

The edible film was sliced into smaller sections to fit into the SEM chamber, ensuring the sample's surface remained flat and uncontaminated for accurate results. The sample was then placed inside the SEM chamber, where its surface morphology was observed. A specific area of the film's surface was then chosen for further analysis using EDS (JEOUL, Japan). The EDS measurement process began with the activation of the EDS detector on the SEM, followed by focusing the electron beam on the chosen area. The EDS detector then measured the X-ray energy emitted from the sample as the electron beam interacted with the atoms in the material. The detected X-ray data were converted into a spectrum showing energy peaks corresponding to specific elements in the sample. This spectrum was subsequently analyzed to identify the elements based on the positions of the energy peaks, and the quantification of the elements was performed by comparing the intensity of the resulting peaks (Newbury and Ritchie, 2014).

FTIR

The edible film was affixed to the optical window situated above the ZnSe crystal and compressed with a force of 15 gauge pressure to guarantee intimate contact between the sample and the crystal. Tests were conducted with an IR spectrophotometer (Thermo Fisher Scientific, USA) across the wave number range of 4,000 1/cm, with 16 readings and a resolution of four 1/cm.

Antibacterial activity

The paper disk method for antimicrobial testing begins with preparing a bacterial culture and adjusting the suspension’s turbidity using a McFarland standard solution. The antimicrobial compounds are then tested by placing paper disks soaked with the compounds onto agar plates inoculated with the test microorganism. The effectiveness is indicated by the size of the inhibition zone around the disk. The process starts with preparing a contamination control using Nutrient Agar (NA) media (Merck, Germany) in a sterile petri dish, inoculated with the bacterial suspension. After drying, an antibiotic disk is placed alongside a control disk, then the plate is incubated for 24 h. After incubation, the inhibition zones are measured to determine the antibiotic’s efficacy (Nabilla and Advinda, 2022).

Statistics analysis

The data obtained will be subjected to processing in accordance with a completely randomized design, which employed a range of cinnamon essential oil concentrations, including M1 (0%), M2 (2%), M3 (4%), M4 (6%), and M5 (8%) cinnamon essential oil, with five replications. The data were subjected to statistical evaluation using analysis of variance (ANOVA) in the statistical software package SPSS 24.0. The significance of the observed differences between the means was determined using Duncan's test with a p-value of 0.05.

Results and discussion

Tensile strength

Figure 1 illustrates the tensile strength value of a whey-chia seed edible film with the incorporation of varying concentrations of cinnamon essential oil. The analysis of variance demonstrated that the incorporation of varying concentrations of cinnamon oil did not yield a statistically significant impact (p>0.05). The tensile strength values produced by the whey-chia seed edible film ranged from 1.73±0.45 to 2.53±0.61 MPa. The highest value was observed in the treatment that did not include the addition of cinnamon oil (0%).

Edible films represent a promising alternative to plastic packaging, especially as biodegradable packaging materials. One of the key ingredients used in the development of these films is whey protein, which has the potential to act as a barrier to moisture, oxygen, lipids, and aroma (Schmid, 2013). However, whey protein-based films tend to have limitations in water vapor barrier properties due to their hydrophilic nature (Azevedo et al., 2015; Teixeira et al., 2014). To address this issue, one promising approach is the incorporation of polysaccharides from plant seeds that can form gels, such as chia seeds. Chia seeds are known for their functional properties, including high viscosity in water and positive metabolic effects, making them an ideal material for developing biodegradable films (Chollakup et al., 2020). Additionally, chia seed-based films possess antimicrobial properties, which can help prevent food spoilage and extend product shelf life (Beikzadeh et al., 2020).

The use of essential oils, such as cinnamon essential oil, in these films offers added potential as they have strong antimicrobial properties. The incorporation of essential oils not only enhances the barrier properties of the film but also supports the primary goal of biodegradable packaging to preserve food quality without synthetic preservatives (Zubair et al., 2022). Focusing on the development of biodegradable films using natural materials such as whey, chia, and essential oils provides an environmentally friendly solution for the food packaging industry.

Cinnamon essential oil is an essential oil that can be used to obtain good film characteristics. The incorporation of essential oils can enhance the mechanical properties of the film, thereby extending its shelf-life (Praseptiangga et al., 2021). Cinnamon contains tannins, saponins, and flavonoids that exert an antiseptic effect, damaging microbial cell membranes as a result. Previously, cinnamon essential oil has been employed for the assessment of the mechanical properties of iota-carrageenan films (Praseptiangga et al., 2021). Nevertheless, it is acknowledged that research on whey-based edible films with the addition of cinnamon remains scarce.

Materials and methods

Materials and instruments

This experiment used whey protein, chia seed (Greenara, Indonesia), glycerol (Merck, Germany), NaOH (Merck, Germany), ethanol pro analysis (Merck, Germany), cinnamon essential oil, silica gel, distilled water, label paper, aluminum foil, and clean water. The main instruments used included erlenmeyer (Pyrex, Indonesia), thermometer (Gelsonlab HSGT-067, China), magnetic stirrer, hot plate stirrer (FAITHFUL SH-2, China), desiccator, Attenuated Total Reflection-Fourier Transform Infrared (ATR-FTIR; Perkin Elmer/Spectrum Two), and Scanning Electron Microscope (SEM; JEOL JCM-7,000, Japan).

Chia seed extraction

The chia seeds were subjected to a rigorous four-stage washing process utilizing ethanol, with the objective of eliminating any extraneous materials. Subsequently, the ethanol was extracted from the seeds via filtration, followed by the evaporation of the residual solution in an oven at 70 °C. The seeds were then pulverized into smaller particles using a blender (Miyako, Indonesia). The resulting chia seed granules were then macerated in ethanol at a ratio of 1:5 and soaked for three days. Following this, the chia seed filtrate was filtered using Whatman 41 filter paper. The chia seed filtrate was then subjected to evaporation in a Heidolph Rotary Evaporators - Hei-VAP Value Digital G3 device, resulting in a chia seed solution (Khazaei et al., 2014).

Sample preparation

A total of 25 samples were analyzed from June to November 2024. The predetermined treatment was followed by combining the whey (one g) and chia seeds (one ml), which were then combined with distilled water until the final volume reached 15 ml. The resulting mixture of whey and chia seeds was combined with a 30% glycerol plasticizer and heated on a hot plate at 90±2 °C. Cinnamon essential oil was added at each concentration (0, 2, 4, 6, and 8%) according to the treatment, and the mixture was stirred using a magnetic stirrer at 250 rpm for 30 min. The solution was then neutralized with NaOH until a pH of 7–8 was reached. Subsequently, the film solution was transferred to a petri dish and heated in an oven at 50 °C for a period of two days. Moreover, the completed edible film was covered with aluminum foil before undergoing testing (Fahrullah et al., 2020).

Tensile strength

The tensile strength of the edible film was evaluated through a series of tensile tests, where in the film was cut into 8x3 cm shapes with a diameter of 1.5 cm, attached horizontally to a clamp, and subjected to a tensile force until the film exhibited visible indications of rupture (Wittaya, 2013).

Elongation

The elongation value of the edible film was evaluated utilizing a Universal Instrument Tensile Strength Meter (HongJin, China). The film was divided into 10×5 cm sections prior to being extended at a rate of 50 mm/min. The formula used for film elongation was adopted from (Wardana and Widyaningsih, 2018):

Where, L is the film length at break (mm) and L0 is the initial film length (mm).

Water Vapor Transmission Rate (WVTR)

The WVTR was measured by cutting a circular film with a diameter of 2.8 cm. The film pieces were stored in a glass containing 3 g of silica gel and put in a desiccator, and then measurements were taken every 24 h for 5 days. The WVTR was expressed in units of g/mm2.day using the formula (ASTM, 2005):

Where, n is the change of weight (g), t is time (days), and A is the surface area of the edible film (mm2).

Microstructure film

The microstructures of the edible film were examined using a SEM. The edible film, measuring 0.5×0.5 cm, was coated with carbon and gold. The prepared sample was then placed in the SEM for microstructural observation.

Energy Dispersive X-ray Spectroscopy (EDS)

The edible film was sliced into smaller sections to fit into the SEM chamber, ensuring the sample's surface remained flat and uncontaminated for accurate results. The sample was then placed inside the SEM chamber, where its surface morphology was observed. A specific area of the film's surface was then chosen for further analysis using EDS (JEOUL, Japan). The EDS measurement process began with the activation of the EDS detector on the SEM, followed by focusing the electron beam on the chosen area. The EDS detector then measured the X-ray energy emitted from the sample as the electron beam interacted with the atoms in the material. The detected X-ray data were converted into a spectrum showing energy peaks corresponding to specific elements in the sample. This spectrum was subsequently analyzed to identify the elements based on the positions of the energy peaks, and the quantification of the elements was performed by comparing the intensity of the resulting peaks (Newbury and Ritchie, 2014).

FTIR

The edible film was affixed to the optical window situated above the ZnSe crystal and compressed with a force of 15 gauge pressure to guarantee intimate contact between the sample and the crystal. Tests were conducted with an IR spectrophotometer (Thermo Fisher Scientific, USA) across the wave number range of 4,000 1/cm, with 16 readings and a resolution of four 1/cm.

Antibacterial activity

The paper disk method for antimicrobial testing begins with preparing a bacterial culture and adjusting the suspension’s turbidity using a McFarland standard solution. The antimicrobial compounds are then tested by placing paper disks soaked with the compounds onto agar plates inoculated with the test microorganism. The effectiveness is indicated by the size of the inhibition zone around the disk. The process starts with preparing a contamination control using Nutrient Agar (NA) media (Merck, Germany) in a sterile petri dish, inoculated with the bacterial suspension. After drying, an antibiotic disk is placed alongside a control disk, then the plate is incubated for 24 h. After incubation, the inhibition zones are measured to determine the antibiotic’s efficacy (Nabilla and Advinda, 2022).

Statistics analysis

The data obtained will be subjected to processing in accordance with a completely randomized design, which employed a range of cinnamon essential oil concentrations, including M1 (0%), M2 (2%), M3 (4%), M4 (6%), and M5 (8%) cinnamon essential oil, with five replications. The data were subjected to statistical evaluation using analysis of variance (ANOVA) in the statistical software package SPSS 24.0. The significance of the observed differences between the means was determined using Duncan's test with a p-value of 0.05.

Results and discussion

Tensile strength

Figure 1 illustrates the tensile strength value of a whey-chia seed edible film with the incorporation of varying concentrations of cinnamon essential oil. The analysis of variance demonstrated that the incorporation of varying concentrations of cinnamon oil did not yield a statistically significant impact (p>0.05). The tensile strength values produced by the whey-chia seed edible film ranged from 1.73±0.45 to 2.53±0.61 MPa. The highest value was observed in the treatment that did not include the addition of cinnamon oil (0%).

Figure 1: Tensile strength of whey-chia seed films varying cinnamon oil comcentrations

M1=0% cinnamon essential oil; M2=2% cinnamon essential oil; M3=4% cinnamon essential oil: M4=6% cinnamon essential oil; M5=8% cinnamon essential oil

The addition of a high concentration of cinnamon essential oil resulted in a notable decrease in the measured parameter. The reduction in tensile strength observed in the edible film was attributed to the ability of the cinnamon essential oil to effectively penetrate the biopolymer network, which subsequently resulted in a decrease in intra- and intermolecular interactions within the film. This occurs as a result of the replacement of the stronger polymer-polymer interactions with weaker polymer-oil interactions within the film matrix (Sun et al., 2020). The incorporation of compounds with hydrophobic bonds into the film solution reduces tensile strength but may enhance the film’s percentage elongation (Sharma et al., 2020). This suggests that larger oil droplet sizes impair the integrity of the internal structure and hinder the formation of inter- and intramolecular hydrogen bonds, resulting in a looser and coarser internal structure, as well as a reduction in the mechanical properties of the blended film (Zhao et al., 2022). When cinnamon essential oil interacts with polymer chains, it replaces the majority of the strong interactions between polymer molecules with weaker interactions between polymer and oil molecules (Kumar V et al., 2022). The integration of essential oils into polymer films often reduces the mechanical strength and alters the structural properties due to the disruption of the intermolecular bonds in the polymer matrix (Espitia et al., 2014). Prior research has demonstrated that essential oils exert a plasticizing effect on biopolymers, reducing the strength of intermolecular bonds within the polymer matrix and thereby enhancing the flexibility of the film until it reaches its tensile strength limit and begins to crack (Wen et al., 2016).

Elongation

Figure 2 illustrates the effect of varying the concentration of plasticizer and cinnamon essential oil on the elongation value of the whey-chia seed edible film. The results of the analysis of variance demonstrated that the incorporation of cinnamon oil did not exert a statistically significant impact on the elongation of the resulting film (p>0.05). The resulting elongation value ranged from 64.94±18.43 to 77.36±1.43%. It was observed that as the concentration of cinnamon oil increased, the elongation value decreased.

Despite the observed reduction in elongation values associated with elevated concentrations of cinnamon essential oil, the resulting values remained within the limits specified by the Japanese Industrial Standard (JIS). The incorporation of this essential oil may influence the physical and chemical configuration of the polymer matrix (Zhou et al., 2021). At low concentrations, these cinnamon essential oils may be well distributed without interfering with polymer interactions. Nevertheless, at elevated concentrations, cinnamon essential oil may act as a disruptive agent, influencing the intermolecular polymer bonds, which reduces the film’s elasticity and flexibility, leading to a decrease in elongation. The observed decrease in elongation value with increasing in cinnamon essential oil concentration can be explained by the mechanism whereby essential oils that are hydrophobic in nature can disrupt polymer networks that are normally hydrophilic in nature. An increase in essential oil concentration in protein-based films tends to result in an uneven distribution of the oil, which creates microstructures within the film. This leads to a decrease in flexibility and an increase in brittleness. The elongation percentage of this edible film has been demonstrated to meet the elongation standard of 70% set by the JIS. Materials with high elongation values demonstrate excellent flexibility as a result of robust intermolecular bonding between polymer molecules (Lorevice et al., 2016).

Elongation

Figure 2 illustrates the effect of varying the concentration of plasticizer and cinnamon essential oil on the elongation value of the whey-chia seed edible film. The results of the analysis of variance demonstrated that the incorporation of cinnamon oil did not exert a statistically significant impact on the elongation of the resulting film (p>0.05). The resulting elongation value ranged from 64.94±18.43 to 77.36±1.43%. It was observed that as the concentration of cinnamon oil increased, the elongation value decreased.

Despite the observed reduction in elongation values associated with elevated concentrations of cinnamon essential oil, the resulting values remained within the limits specified by the Japanese Industrial Standard (JIS). The incorporation of this essential oil may influence the physical and chemical configuration of the polymer matrix (Zhou et al., 2021). At low concentrations, these cinnamon essential oils may be well distributed without interfering with polymer interactions. Nevertheless, at elevated concentrations, cinnamon essential oil may act as a disruptive agent, influencing the intermolecular polymer bonds, which reduces the film’s elasticity and flexibility, leading to a decrease in elongation. The observed decrease in elongation value with increasing in cinnamon essential oil concentration can be explained by the mechanism whereby essential oils that are hydrophobic in nature can disrupt polymer networks that are normally hydrophilic in nature. An increase in essential oil concentration in protein-based films tends to result in an uneven distribution of the oil, which creates microstructures within the film. This leads to a decrease in flexibility and an increase in brittleness. The elongation percentage of this edible film has been demonstrated to meet the elongation standard of 70% set by the JIS. Materials with high elongation values demonstrate excellent flexibility as a result of robust intermolecular bonding between polymer molecules (Lorevice et al., 2016).

Figure 2: Elongation of whey-chia seed films with varying cinnamon oil concentrations

M1=0% cinnamon essential oil; M2=2% cinnamon essential oil; M3=4% cinnamon essential oil: M4=6% cinnamon essential oil; M5=8% cinnamon essential oil

WVTR

The results of the analysis of variance demonstrated that the incorporation of cinnamon essential oil concentration exerted a statistically significant impact (p<0.01) on the WVTR of the resultant films. The water vapor transmission rate value exhibited a range of 6.01±0.92–13.44±0.44 g/mm².day. As the concentration of cinnamon oil increased, the WVTR also increased (Figure 3).

The findings of the study, which employed varying concentrations of cinnamon essential oil, indicated a statistically significant impact (p<0.01) on the WVTR value of the whey-chia seed edible film produced. A consistent correlation was observed between an increase in cinnamon essential oil concentration and an increase in WVTR value. This suggests that the essential oil exerts a more pronounced influence on the water vapor permeability characteristics of the edible film. Conversely, the findings indicated that an elevation in cinnamon oil concentration was linked to an augmentation in the WVTR value. This indicates that cinnamon essential oil has a more pronounced effect on the water vapor permeability of whey-chia seed edible films. This result is consistent with the findings of other studies which demonstrate that the composition of essential oils can affect the mechanical and physical properties of edible films, particularly in relation to water vapor permeability (Dag et al., 2023; Yu et al., 2023). Cinnamon essential oil, due to its hydrophobic properties, has the potential to influence the distribution of water within the film and alter the film's microstructure. At higher concentrations, cinnamon essential oil has the potential to disrupt the polymer matrix, resulting in a more heterogeneous structure, and potentially creating an easier diffusion path for water vapor, which could consequently increase the WVTR (Noori and Marashi, 2023). In essence, the WVTR value is contingent upon the movement of water molecules through the film. The combination of glycerol, a plasticizer, with cinnamon essential oil alters the structure of the film, either by increasing the distance between molecules or creating more accessible diffusion pathways, which consequently elevates the WVTR value (Bahram et al., 2014).

The results of the analysis of variance demonstrated that the incorporation of cinnamon essential oil concentration exerted a statistically significant impact (p<0.01) on the WVTR of the resultant films. The water vapor transmission rate value exhibited a range of 6.01±0.92–13.44±0.44 g/mm².day. As the concentration of cinnamon oil increased, the WVTR also increased (Figure 3).

The findings of the study, which employed varying concentrations of cinnamon essential oil, indicated a statistically significant impact (p<0.01) on the WVTR value of the whey-chia seed edible film produced. A consistent correlation was observed between an increase in cinnamon essential oil concentration and an increase in WVTR value. This suggests that the essential oil exerts a more pronounced influence on the water vapor permeability characteristics of the edible film. Conversely, the findings indicated that an elevation in cinnamon oil concentration was linked to an augmentation in the WVTR value. This indicates that cinnamon essential oil has a more pronounced effect on the water vapor permeability of whey-chia seed edible films. This result is consistent with the findings of other studies which demonstrate that the composition of essential oils can affect the mechanical and physical properties of edible films, particularly in relation to water vapor permeability (Dag et al., 2023; Yu et al., 2023). Cinnamon essential oil, due to its hydrophobic properties, has the potential to influence the distribution of water within the film and alter the film's microstructure. At higher concentrations, cinnamon essential oil has the potential to disrupt the polymer matrix, resulting in a more heterogeneous structure, and potentially creating an easier diffusion path for water vapor, which could consequently increase the WVTR (Noori and Marashi, 2023). In essence, the WVTR value is contingent upon the movement of water molecules through the film. The combination of glycerol, a plasticizer, with cinnamon essential oil alters the structure of the film, either by increasing the distance between molecules or creating more accessible diffusion pathways, which consequently elevates the WVTR value (Bahram et al., 2014).

Figure 3: Water Vapor Transmission Rate (WVTR) of whey-chia seed films with varying cinnamon oil concentrations

M1=0% cinnamon essential oil; M2=2% cinnamon essential oil; M3=4% cinnamon essential oil: M4=6% cinnamon essential oil; M5=8% cinnamon essential oil

Microstructure film

The objective of this study is to observe the microstructure of a whey-chia seed film with the addition of different types of plasticisers and varying concentrations of cinnamon oil using a SEM. This will reveal and show the constituent particles contained in the film. The value of this microstructure observation lies in its capacity to elucidate the relationship between the material's intrinsic properties and the structural and defect characteristics that emerge within it. The research yielded the microstructure depicted in Figure 4, which resulted from applying distinct treatments, namely the utilization of diverse plasticizer and varying concentrations of cinnamon oil, with an image magnification of 3,000 times.

The surface and cross-sectional structure and properties of the film exhibited changes in response to variations in the concentration of cinnamon essential oil. Films with a lower concentration of cinnamon essential oil exhibited a surface that was slightly more homogeneous and smooth in comparison to films with a high concentration. Additionally, the structure of the former films was devoid of any holes or gaps. However, as the concentration of cinnamon essential oil increased, the film surface became visibly granular, indicating a potential incompatibility between the emulsion and the polymer particles of the film, which may have resulted in a rougher surface. It is conceivable that the flocculation and emulsification of cinnamon essential oil during the film-drying process may have resulted in the formation of oil droplets on the film surface and an elevated volatility of the essential oil on the film surface (Song et al., 2018). Moreover, an increase in bubbles was observed in the cross-section of the edible film, resulting in the formation of cavities (Chu et al., 2020). These findings are corroborated by the assessment of physical properties, including elongation and tensile strength. As the concentration of cinnamon essential oil increases, the elongation rate decreases. Consequently, the regularity of the film structure is contingent upon the concentration and thickness of the essential oil (Zhao et al., 2022). The utilization of glycerol has the potential to result in a film surface that is smoother and more homogeneous, with a more elastic cross-section (Saberi et al., 2017). The addition of glycerol typically results in a reduction in the number of cracks or fissures observed in the microstructure, due to its ability to enhance the plasticity and extensibility of the film (Rezaei and Motamedzadegan, 2015). The present findings demonstrate a congruence with the results obtained by (Fahrullah et al., 2020), who discovered that the application of glycerol in whey-konjac edible films yielded a more uniform microstructure. It is established that there is a close relationship between the microstructure of edible films and their physical characteristics. The formation of a flat surface structure is the result of effective film-making techniques and mixing processes. The heating method, homogenization process, emulsion composition, and structural components at the conclusion of the drying process are the determining factors in the microstructure of the film (Liu et al., 2022).

EDS

EDS is an analytical technique used to determine the elemental composition of materials. When applied to edible films, EDS can provide insight into their chemical composition. Figure 5 illustrates the identification of elements present in a whey-chia seed edible film utilizing glycerol as a plasticizer and the incorporation of varying concentrations of cinnamon essential oil. The peak observed at approximately 0.3 keV is indicative of carbon’s (C-K) presence, which is the primary constituent of all organic components present in the film, including whey, chia seed, and glycerol. The oxygen (O-K) peak observed at approximately 0.5 keV indicates the presence of oxygen in organic compounds and glycerol, which serves as the film matrix. The carbon and oxygen peaks remain dominant due to the addition of cinnamon essential oil, increasing in intensity compared to the spectrum without cinnamon. The dominance of carbon and oxygen indicates that the film has a strong organic composition, and this increase confirms that cinnamon essential oil has been successfully incorporated into the film matrix. The observed increase substantiates the successful incorporation of cinnamon essential oil into the film matrix. Cinnamon essential oil, which is a complex compound, contributes to the carbon and oxygen peaks due to the presence of components such as aldehydes, phenols, and terpenoids. The presence of sodium (Na-K) and calcium (Ca-K) is indicated by a small peak around one keV, while the Ca-K peaks are observed at approximately 0.35 and 3.7 keV. The intensities remain relatively stable, indicating that the concentration of these elements is not affected by the addition of cinnamon oil. The presence of Ca-K and Na-K is intrinsic to the chia seed and whey matrix, yet their intensity is considerably less than that of carbon and oxygen. The EDS spectra show that increasing cinnamon essential oil levels correspond to higher carbon and oxygen concentrations, while maintaining minor elements like Na-K and Ca-K. A comparison of EDS spectra at various concentrations of cinnamon essential oil (2, 4, 6, and 8%) revealed that the addition of cinnamon essential oil resulted in a proportional increase in peak intensities of carbon and oxygen, while minor elements such as Na-K, chlorine, and Ca-K remained stable.

The objective of this study is to observe the microstructure of a whey-chia seed film with the addition of different types of plasticisers and varying concentrations of cinnamon oil using a SEM. This will reveal and show the constituent particles contained in the film. The value of this microstructure observation lies in its capacity to elucidate the relationship between the material's intrinsic properties and the structural and defect characteristics that emerge within it. The research yielded the microstructure depicted in Figure 4, which resulted from applying distinct treatments, namely the utilization of diverse plasticizer and varying concentrations of cinnamon oil, with an image magnification of 3,000 times.

The surface and cross-sectional structure and properties of the film exhibited changes in response to variations in the concentration of cinnamon essential oil. Films with a lower concentration of cinnamon essential oil exhibited a surface that was slightly more homogeneous and smooth in comparison to films with a high concentration. Additionally, the structure of the former films was devoid of any holes or gaps. However, as the concentration of cinnamon essential oil increased, the film surface became visibly granular, indicating a potential incompatibility between the emulsion and the polymer particles of the film, which may have resulted in a rougher surface. It is conceivable that the flocculation and emulsification of cinnamon essential oil during the film-drying process may have resulted in the formation of oil droplets on the film surface and an elevated volatility of the essential oil on the film surface (Song et al., 2018). Moreover, an increase in bubbles was observed in the cross-section of the edible film, resulting in the formation of cavities (Chu et al., 2020). These findings are corroborated by the assessment of physical properties, including elongation and tensile strength. As the concentration of cinnamon essential oil increases, the elongation rate decreases. Consequently, the regularity of the film structure is contingent upon the concentration and thickness of the essential oil (Zhao et al., 2022). The utilization of glycerol has the potential to result in a film surface that is smoother and more homogeneous, with a more elastic cross-section (Saberi et al., 2017). The addition of glycerol typically results in a reduction in the number of cracks or fissures observed in the microstructure, due to its ability to enhance the plasticity and extensibility of the film (Rezaei and Motamedzadegan, 2015). The present findings demonstrate a congruence with the results obtained by (Fahrullah et al., 2020), who discovered that the application of glycerol in whey-konjac edible films yielded a more uniform microstructure. It is established that there is a close relationship between the microstructure of edible films and their physical characteristics. The formation of a flat surface structure is the result of effective film-making techniques and mixing processes. The heating method, homogenization process, emulsion composition, and structural components at the conclusion of the drying process are the determining factors in the microstructure of the film (Liu et al., 2022).

EDS

EDS is an analytical technique used to determine the elemental composition of materials. When applied to edible films, EDS can provide insight into their chemical composition. Figure 5 illustrates the identification of elements present in a whey-chia seed edible film utilizing glycerol as a plasticizer and the incorporation of varying concentrations of cinnamon essential oil. The peak observed at approximately 0.3 keV is indicative of carbon’s (C-K) presence, which is the primary constituent of all organic components present in the film, including whey, chia seed, and glycerol. The oxygen (O-K) peak observed at approximately 0.5 keV indicates the presence of oxygen in organic compounds and glycerol, which serves as the film matrix. The carbon and oxygen peaks remain dominant due to the addition of cinnamon essential oil, increasing in intensity compared to the spectrum without cinnamon. The dominance of carbon and oxygen indicates that the film has a strong organic composition, and this increase confirms that cinnamon essential oil has been successfully incorporated into the film matrix. The observed increase substantiates the successful incorporation of cinnamon essential oil into the film matrix. Cinnamon essential oil, which is a complex compound, contributes to the carbon and oxygen peaks due to the presence of components such as aldehydes, phenols, and terpenoids. The presence of sodium (Na-K) and calcium (Ca-K) is indicated by a small peak around one keV, while the Ca-K peaks are observed at approximately 0.35 and 3.7 keV. The intensities remain relatively stable, indicating that the concentration of these elements is not affected by the addition of cinnamon oil. The presence of Ca-K and Na-K is intrinsic to the chia seed and whey matrix, yet their intensity is considerably less than that of carbon and oxygen. The EDS spectra show that increasing cinnamon essential oil levels correspond to higher carbon and oxygen concentrations, while maintaining minor elements like Na-K and Ca-K. A comparison of EDS spectra at various concentrations of cinnamon essential oil (2, 4, 6, and 8%) revealed that the addition of cinnamon essential oil resulted in a proportional increase in peak intensities of carbon and oxygen, while minor elements such as Na-K, chlorine, and Ca-K remained stable.

|

a

|

|

b

|

|

c

|

|

d

|

|

e

|

Figure 4: Microstructure of whey–chia seed film with addition of: (a) 0% cinnamon essential oil; (b) 2% cinnamon essential oil; (c) 4% cinnamon essential oil; (d) 6% cinnamon essential oil; and (e) 8% cinnamon essential oil in 3,000 times

FTIR

FTIR spectroscopy is a technique employed to identify and analyze the functional groups present in materials by measuring infrared absorption at various frequencies. In the context of a whey-chia seed-based edible film with glycerol as a plasticizer and cinnamon oil addition, FTIR can be employed to examine the chemical interactions between the components, as well as the structural alterations that occur as a consequence of the incorporation of these ingredients. An overview of the FTIR results is provided in Figure 6.

FTIR spectroscopy is a technique employed to identify and analyze the functional groups present in materials by measuring infrared absorption at various frequencies. In the context of a whey-chia seed-based edible film with glycerol as a plasticizer and cinnamon oil addition, FTIR can be employed to examine the chemical interactions between the components, as well as the structural alterations that occur as a consequence of the incorporation of these ingredients. An overview of the FTIR results is provided in Figure 6.

Figure 5: Energy Dispersive X-ray Spectroscopy (EDS) of whey–chia seed film with addition of: (0b) 0% cinnamon essential oil; (2b) 2% cinnamon essential oil; (4b) 4% cinnamon essential oil; (6b) 6% cinnamon essential oil; and (8b) 8% cinnamon essential oil

Figure 6: Fourier Transform Infrared (FTIR) of whey–chia seed film with addition of: (a) 0% cinnamon essential oil; (b) 2% cinnamon essential oil; (c) 4% cinnamon essential oil; (d) 6% cinnamon essential oil; and (e) 8% cinnamon essential oil

Figure 6 illustrates the FTIR analysis of whey-chia seed edible films with varying cinnamon essential oil concentrations. This addition resulted in a notable shift in the absorption wave; the film without the addition of cinnamon essential oil (0%) produced an absorption wave of 3,288.50 1/cm and the film with the addition of 2% cinnamon essential oil produced a sharp peak at 3,290.66 1/cm. The mean absorption peak observed is approximately 3,200 1/cm. This absorption peak is attributed to the hydroxyl group (-OH). This absorption band is derived from the -OH groups present in glycerol, whey, and chia seed. Absorption at 2,800-2,900 1/cm indicates the presence of C-H bonds in alkyl chains or hydrocarbon compounds, as a result of C-H stretching in alkane groups. The 1,600 1/cm absorption band is indicative of C=O stretching, which is characteristic of carbonyl groups. This is a distinct, sharp peak, which is characteristic of a C=O double bond. This absorption band can be attributed to the presence of whey protein and fatty acids in chia seeds, as well as the aldehyde component of cinnamon essential oil. The absorption band with a wavelength of 1,500 1/cm is associated with N-H bending or C=C stretching in aromatic compounds, as observed in this case with cinnamon oil. This indicates the presence of double bonds or amide groups. Moreover, the absorption band with a wavelength of 1,400 1/cm can be attributed to C-H bending in alkanes or C=C in aromatic compounds (cinnamon essential oil). Cinnamon essential oil exhibits a series of distinctive peaks at 688, 748, and 1,451 1/cm , which are attributed to the phenyl group of cinnamaldehyde (Chen et al., 2016). These peaks indicate the presence of double bonds in the molecule or methyl groups in the alkane structure. The absorption band observed at approximately 1,000-1,300 1/cm is indicative of the presence of ether bonds (C-O-C). This suggests the presence of polysaccharides derived from chia seeds, as well as a contribution from glycerol. The addition of glycerol as a plasticizer to an edible film will result in increased flexibility, due to its ability to interact with protein chains and polysaccharides. This interaction occurs primarily through hydrogen bonding with the -OH groups present in these molecules. Cinnamon essential oil contains active compounds, including cinnamaldehyde, eugenol, and coumarin, which can interact with proteins and polysaccharides in the film through hydrogen bonds and hydrophobic interactions (Zhao et al., 2022). Such a shift or change in intensity in the absorption bands associated with the -OH and C=O groups would indicate an interaction between the film components and cinnamon essential oil. A shift in the absorption peak may indicate an increase in the homogeneity or stability of the interaction between the film components, which is crucial for the physical qualities of the film, including mechanical strength and barrier properties (Zhang et al., 2020). The incorporation of cinnamon essential oil into the film matrix is compatible with other film-forming components, which is advantageous for the release of its active ingredients (Zhao et al., 2022).

Antibacterial activity

The antibacterial activity of the whey-chia seed edible film containing cinnamon essential oil are presented in Table 1. Analysis of variance demonstrated that the addition of cinnamon oil significantly (p<0.01) inhibited Escherichia coli and Staphylococcus aureus.

The antibacterial effect demonstrated a positive correlation with the concentration of cinnamon essential oil (Table 1). Cinnamon essential oil has been demonstrated to possess considerable antibacterial activity against food-borne bacteria and spoilage microorganisms (Lucas-González et al., 2023). Nevertheless, the direct use of this substance in food is limited by its hydrophobic properties, aroma characteristics, and chemical instability when exposed to oxygen, light, and high storage temperatures (Ebrahimzadeh et al., 2021). As illustrated in Table 1, the antibacterial efficacy of the whey-chia seed edible film was evaluated using E. coli and S. aureus. Films containing cinnamon essential oil demonstrated varying degrees of activity against the bacteria under examination. Notably, the findings indicated that the film demonstrated enhanced efficacy against S. aureus (Liu et al., 2022; Wen et al., 2016), while other studies have demonstrated that cinnamon oil is more efficacious against E. coli bacteria (Bandyopadhyay et al., 2020) and exhibits an inhibitory effect against both E. coli and S. aureus ( Khazaei et al., 2021). In general, microbial growth inhabitation increased in accordance with the concentration level. The incorporation of cinnamon essential oil has been demonstrated to enhance the inhibitory impact on bacterial proliferation within an edible film matrix through the utilization of an emulsion Pickering system (Lucas-González et al., 2023). The inhibition zone produced by the whey-chia seed edible film on E. coli bacteria was found to be 9.35-12 mm (medium/intermediate), while that produced on S. aureus bacteria was 10.70-14.60 mm (medium/intermediate). The antibacterial efficacy of cinnamon essential oil is contingent upon the concentration and ratio of cinnamaldehyde and eugenol (Han et al., 2018). The contents of cinnamaldehyde and eugenol have been demonstrated to exert inhibitory effects on both Gram-negative and Gram-positive bacteria. The principal component of cinnamon essential oil, cinnamaldehyde, has a mechanism of action that involves the destruction of bacterial cell membranes, the disruption of enzyme function and the damage of protein structures within bacterial cells (Khazaei et al., 2021). This results in the leakage of cell contents and the subsequent death of the bacterial cell.

Antibacterial activity

The antibacterial activity of the whey-chia seed edible film containing cinnamon essential oil are presented in Table 1. Analysis of variance demonstrated that the addition of cinnamon oil significantly (p<0.01) inhibited Escherichia coli and Staphylococcus aureus.

The antibacterial effect demonstrated a positive correlation with the concentration of cinnamon essential oil (Table 1). Cinnamon essential oil has been demonstrated to possess considerable antibacterial activity against food-borne bacteria and spoilage microorganisms (Lucas-González et al., 2023). Nevertheless, the direct use of this substance in food is limited by its hydrophobic properties, aroma characteristics, and chemical instability when exposed to oxygen, light, and high storage temperatures (Ebrahimzadeh et al., 2021). As illustrated in Table 1, the antibacterial efficacy of the whey-chia seed edible film was evaluated using E. coli and S. aureus. Films containing cinnamon essential oil demonstrated varying degrees of activity against the bacteria under examination. Notably, the findings indicated that the film demonstrated enhanced efficacy against S. aureus (Liu et al., 2022; Wen et al., 2016), while other studies have demonstrated that cinnamon oil is more efficacious against E. coli bacteria (Bandyopadhyay et al., 2020) and exhibits an inhibitory effect against both E. coli and S. aureus ( Khazaei et al., 2021). In general, microbial growth inhabitation increased in accordance with the concentration level. The incorporation of cinnamon essential oil has been demonstrated to enhance the inhibitory impact on bacterial proliferation within an edible film matrix through the utilization of an emulsion Pickering system (Lucas-González et al., 2023). The inhibition zone produced by the whey-chia seed edible film on E. coli bacteria was found to be 9.35-12 mm (medium/intermediate), while that produced on S. aureus bacteria was 10.70-14.60 mm (medium/intermediate). The antibacterial efficacy of cinnamon essential oil is contingent upon the concentration and ratio of cinnamaldehyde and eugenol (Han et al., 2018). The contents of cinnamaldehyde and eugenol have been demonstrated to exert inhibitory effects on both Gram-negative and Gram-positive bacteria. The principal component of cinnamon essential oil, cinnamaldehyde, has a mechanism of action that involves the destruction of bacterial cell membranes, the disruption of enzyme function and the damage of protein structures within bacterial cells (Khazaei et al., 2021). This results in the leakage of cell contents and the subsequent death of the bacterial cell.

Table 1: The average diameter of the resistance zone (mm) of cinnamon oil againts Escherichia coli and Staphylococcus aureus

| Treatment | Inhibition (mm) | |

| Escherichia coli | Staphylococcus aureus | |

| M1 | 0.00±0.00 a | 0.00±0.00 p |

| M2 | 11.20±3.78 b | 13.30±2.18 qr |

| M3 | 10.60±4.70 b | 14.20±2.54 r |

| M4 | 10.70±2.63 b | 10.70±1.51 q |

| M5 | 11.35±2.54 b | 14.60±2.66 r |

superscripts in the same column is indicative of a significant difference (p<0.01).

M1=0% cinnamon essential oil; M2=2% cinnamon essential oil; M3=4% cinnamon essential oil: M4=6% cinnamon essential oil; M5=8% cinnamon essential oil

M1=0% cinnamon essential oil; M2=2% cinnamon essential oil; M3=4% cinnamon essential oil: M4=6% cinnamon essential oil; M5=8% cinnamon essential oil

Conclusion

The increase in cinnamon essential oil concentration significantly improved tensile strength, WVTR, and antibacterial activity. The 8% cinnamon essential oil concentration was found to be the most effective, exhibiting the highest tensile strength (2.53 MPa), elongation (64.94%), WVTR (9.43 g/mm².day), and inhibition zones against E. coli (11.35 mm) and S. aureus (14.60 mm). A limitation of this study is the exclusive use of cinnamon essential oil; future research could investigate other essential oils or combinations to further enhance film properties. Additionally, the long-term stability and environmental impact of these films remain areas for future investigation. The practical applications of this research include the developing sustainable, antimicrobial food packaging, which could offer benefits consumers by reducing plastic waste and support local authorities in promoting environmentally friendly practices.

Author contributions

F.F. and D.K. designed the study; F.F. conducted the experimental work; F.F. and A.N. analyzed the data; F.F., D.K., and A.N. wrote the manuscript. All the authors read and approved the final manuscript.

Conflicts of interest

The authors have no conflict of interest.

Acknowledgments

The authors acknowledge the Directorate of Research, Technology, and Community Services (DRTPM), Ministry of Education, Culture, Research, and Technology of the Republic of Indonesia, for funding this research, through Fundamental-Regular Research with grant number: 060/E5/PG.02.00.PL/2024.

Funding

This research was supported by a grant from the Directorate of Research, Technology, and Community Service (DRTPM), Ministry of Education, Culture, Research, and Technology, Indonesia.

Ethical consideration

Not applicable.

References

Aleksanyan K.V. (2023). Polysaccharides for biodegradable packaging materials: past, present, and future (brief review). Polymers. 15: 451. [DOI: 10.3390/polym15020451]

American Society for Testing and Materials (ASTM). (2005). Standard test methods for water vapor transmission of materials. ASTM E96/E96M – 05. ASTM International, United States. URL: https://cdn.standards.iteh.ai/samples/41444/ee99c0b797cc4ae1a9f6d85416ae1302/ASTM-E96-E96M-05.pdf. Accessed 20 October 2024.

Azevedo V.M., Silva E.K., Pereira C.F.G., Da Costa J.M.G., Borges S.V. (2015). Whey protein isolate biodegradable films: influence of the citric acid and montmorillonite clay nanoparticles on the physical properties. Food Hydrocolloids. 43: 252-258. [DOI: 10.1016/j.foodhyd.2014.05.027]

Bahram S., Rezaei M., Soltani M., Kamali A., Ojagh S.M., Abdollahi M. (2014). Whey protein concentrate edible film activated with cinnamon essential oil. Journal of Food Processing and Preservation. 38: 1251-1258. [DOI: 10.1111/jfpp.12086]

Bandyopadhyay S., Saha N., Zandraa O., Pummerová M., Sáha P. (2020). Essential oil based PVP-CMC-BC-GG functional hydrogel sachet for ‘cheese’: its shelf life confirmed with anthocyanin (isolated from red cabbage) bio stickers. Foods. 9: 307. [DOI: 10.3390/foods9030307]

Beikzadeh S., Khezerlou A., Jafari S.M., Pilevar Z., Mortazavian A.M. (2020). Seed mucilages as the functional ingredients for biodegradable films and edible coatings in the food industry. Advances in Colloid and Interface Science. 280: 102164. [DOI: 10.1016/j.cis.2020.102164]

Chen H., Hu X., Chen E., Wu S., McClements D.J., Liu S., Li B., Li Y. (2016). Preparation, characterization, and properties of chitosan films with cinnamaldehyde nanoemulsions. Food Hydrocolloids. 61: 662-671. [DOI: 10.1016/j.foodhyd.2016.06.034]

Chollakup R., Pongburoos S., Boonsong W., Khanoonkon N., Kongsin K., Sothornvit R., Sukyai P., Sukatta U., Harnkarnsujarit N. (2020). Antioxidant and antibacterial activities of cassava starch and whey protein blend films containing rambutan peel extract and cinnamon oil for active packaging. LWT. 130: 109573. [DOI: 10.1016/j.lwt.2020.109573]

Chu Y., Cheng W., Feng X., Gao C., Wu D., Meng L., Zhang,Y., Tang X. (2020). Fabrication, structure and properties of pullulan-based active films incorporated with ultrasound-assisted cinnamon essential oil nanoemulsions. Food Packaging and Shelf Life. 25: 100547. [DOI: 10.1016/j.fpsl.2020.100547]

Dag D., Jung J., Zhao Y. (2023). Development and characterization of cinnamon essential oil incorporated active, printable and heat sealable cellulose nanofiber reinforced hydroxypropyl methylcellulose films. Food Packaging and Shelf Life. 39: 101153. [DOI: 10.1016/j.fpsl.2023.101153]

De Dicastillo C.L., Rodríguez F., Guarda A., Galotto M.J. (2016). Antioxidant films based on cross-linked methyl cellulose and native chilean berry for food packaging applications. Carbohydrate Polymers. 136: 1052-1060. [DOI: 10.1016/j.carbpol.2015.10.013]

Ebrahimzadeh S., Bari M.R., Hamishehkar H., Kafil H.S., Lim L.-T. (2021). Essential oils-loaded electrospun chitosan-poly(vinyl alcohol) nonwovens laminated on chitosan film as bilayer bioactive edible films. LWT. 144: 111217. [DOI: 10.1016/j.lwt.2021.111217]

Espitia P.J.P., Du W.-X., Avena-Bustillos R.D.J., Soares N.D.F.F., McHugh T.H. (2014). Edible films from pectin: physical-mechanical and antimicrobial properties - a review. Food Hydrocolloids. 35: 287-296. [DOI: 10.1016/j.foodhyd.2013.06.005]

Fahrullah F., Ervandi M., Rosyidi D. (2021). Characterization and antimicrobial activity of whey edible film composite enriched with clove essential oil. Tropical Animal Science Journal. 44: 369-376. [DOI: 10.5398/tasj.2021.44.3.369]

Fahrullah F., Noersidiq A., Maruddin F. (2022). Effects of glycerol plasticizer on physical characteristic of whey-konjac films enriched with clove essential oil. Journal of Food Quality and Hazards Control. 9: 226-233. [DOI: 10.18502/jfqhc.9.4.11377]

Fahrullah F., Radiati L.E., Purwadi , Rosyidi D. (2020). The physical characteristics of whey based edible film added with konjac. Current Research in Nutrition and Food Science. 8: 333-339. [DOI: 10.12944/CRNFSJ.8.1.31]

Han Y., Yu M., Wang L. (2018). Physical and antimicrobial properties of sodium alginate/carboxymethyl cellulose films incorporated with cinnamon essential oil. Food Packaging and Shelf Life. 15: 35-42. [DOI: 10.1016/j.fpsl.2017.11.001]

Herrera-vázquez S.E., Dublán-García O., Arizmendi-Cotero D., Gómez-Oliván L.M., Islas-Flores H., Hernández-Navarro M.D., Ramírez-Durán N. (2022). Optimization of the physical, optical and mechanical properties of composite edible films of gelatin, whey protein and chitosan. Molecules. 27: 869. [DOI: 10.3390/molecules27030869]

Khazaei A., Nateghi L., Zand N., Oromiehie A., Garavand F. (2021). Evaluation of physical, mechanical and antibacterial properties of pinto bean starch-polyvinyl alcohol biodegradable films reinforced with cinnamon essential oil. Polymers. 13: 2778. [DOI: 10.3390/polym13162778]

Khazaei N., Esmaiili M., Emam Djomeh Z., Ghasemlou M., Jouki M. (2014). Characterization of new biodegradable edible film made from basil seed (Ocimum basilicum L.) gum. Carbohydrate Polymers. 102: 199-206. [DOI: 10.1016/j.carbpol.2013.10.062]

Kumar V A., Hasan M., Mangaraj S., Pravitha M., Verma D.K., Srivastav P.P. (2022). Trends in edible packaging films and its prospective future in food: a eview. Applied Food Research. 2: 100118. [DOI: 10.1016/j.afres.2022.100118]

Liu J., Song F., Chen R., Deng G., Chao Y., Yang Z., Wu H., Bai M., Zhang P., Hu Y. (2022). Effect of cellulose nanocrystal-stabilized cinnamon essential oil pickering emulsions on structure and properties of chitosan composite films. Carbohydrate Polymers. 275: 118704. [DOI: 10.1016/j.carbpol. 2021.118704]

Lorevice M.V., Otoni C.G., De Moura M.R., Mattoso L.H.C. (2016). Chitosan nanoparticles on the improvement of thermal, barrier, and mechanical properties of high- and low-methyl pectin films. Food Hydrocolloids. 52: 732-740. [DOI: 10.1016/j.foodhyd.2015.08.003]

Lucas-González R., Yilmaz B., Mousavi Khaneghah A., Hano C., Shariati M.A., Bangar S. P., Goksen G., Dhama K., Lorenzo J.M. (2023). Cinnamon: an antimicrobial ingredient for active packaging. Food Packaging and Shelf Life. 35: 101026. [DOI: 10.1016/j.fpsl.2023.101026]

Mouzakitis C.-K., Sereti V., Matsakidou A., Kotsiou K., Biliaderis C.G., Lazaridou A. (2022). Physicochemical properties of zein-based edible films and coatings for extending wheat bread shelf life. Food Hydrocolloids. 132: 107856. [DOI: 10.1016/j.foodhyd.2022.107856]

Nabilla A., Advinda L. (2022). Antimicrobic activities of solid soap against Staphylococcus aureus and Escherichia coli human pathogen bacteria. Serambi Biologi. 7: 306-310. [DOI: 10.24036/srmb.v7i4.60]. [Indonesian with English abstact]

Newbury D.E., Ritchie N.W.M. (2014). Performing elemental microanalysis with high accuracy and high precision by scanning electron microscopy/silicon drift detector energy-dispersive X-ray spectrometry (SEM/SDD-EDS). Journal of Materials Science. 50: 493-518. [DOI: 10.1007/s10853-014-8685-2]

Nisar T., Wang Z.-C., Yang X., Tian Y., Iqbal M., Guo Y. (2018). Characterization of citrus pectin films integrated with clove bud essential oil: physical, thermal, barrier, antioxidant and antibacterial properties. International Journal of Biological Macromolecules. 106: 670-680. [DOI: 10.1016/j.ijbiomac.2017. 08.068]

Noori S.M.A., Marashi S.M.H. (2023). Chitosan-based coatings and films incorporated with essential oils: applications in food models. Journal of Food Measurement and Characterization. 17: 4060-4072. [DOI: 10.1007/s11694-023-01931-7]

Praseptiangga D., Rahmawati A., Manuhara G.J., Khasanah L.U., Utami R. (2021). Effects of plasticizer and cinnamon essential oil incorporation on mechanical and water barrier properties of semirefined iota-carrageenan-based edible film. IOP Conference Series: Earth and Environmental Science. 828: 012034. [DOI: 10.1088/1755-1315/828/1/012034]

Rezaei M., Motamedzadegan A. (2015). The effect of plasticizers on mechanical properties and water vapor permeability of gelatin-based edible films containing clay nanoparticles. World Journal of Nano Science and Engineering. 5: 178-193. [DOI: 10.4236/wjnse.2015.54019]

Saberi B., Chockchaisawasdee S., Golding J.B., Scarlett C.J., Stathopoulos C.E. (2017). Physical and mechanical properties of a new edible film made of pea starch and guar gum as affected by glycols, sugars and polyols. International Journal of Biological Macromolecules. 104: 345-359. [DOI: 10.1016/j.ijbiomac.2017.06.051]

Schmid M. (2013). Properties of cast films made from different ratios of whey protein isolate, hydrolysed whey protein isolate and glycerol. Materials. 6: 3254-3269. [DOI: 10.3390/ma6083254]

Sharma R., Jafari S.M., Sharma S. (2020). Antimicrobial bio-nanocomposites and their potential applications in food packaging. Food Control. 112: 107086. [DOI: 10.1016/j.foodcont.2020.107086]

Shivangi S., Dorairaj D., Negi P.S., Shetty N.P. (2021). Development and characterisation of a pectin-based edible film that contains mulberry leaf extract and its bio-active components. Food Hydrocolloids. 121: 107046. [DOI: 10.1016/j.foodhyd.2021. 107046]

Song X., Zuo G., Chen F. (2018). Effect of essential oil and surfactant on the physical and antimicrobial properties of corn and wheat starch films. International Journal of Biological Macromolecules. 107: 1302-1309. [DOI: 10.1016/j.ijbiomac. 2017.09.114]

Sun H., Li S., Chen S., Wang C., Liu D., Li X. (2020). Antibacterial and antioxidant activities of sodium starch octenylsuccinate-based pickering emulsion films incorporated with cinnamon essential oil. International Journal of Biological Macromolecules. 159: 696-703. [DOI: 10.1016/j.ijbiomac.2020. 05.118]

Teixeira B., Marques A., Pires C., Ramos C., Batista I., Saraiva J.A., Nunes M.L. (2014). Characterization of fish protein films incorporated with essential oils of clove, garlic and origanum: physical, antioxidant and antibacterial properties. LWT - Food Science and Technology. 59: 533-539. [DOI: 10.1016/j.lwt.2014. 04.024]

Wardana A.A., Widyaningsih T.D. (2018). Development of edible films from tapioca starch and agar, enriched with red cabbage (Brassica oleracea) as a sausage deterioration bio-indicator. IOP Conference Series: Earth and Environmental Science. 109: 012031. [DOI: 10.1088/1755-1315/109/1/012031]

Wen P., Zhu D.-H., Wu H., Zong M.-H., Jing Y.-R., Han S.-Y. (2016). Encapsulation of cinnamon essential oil in electrospun nanofibrous film for active food packaging. Food Control. 59: 366-376. [DOI: 10.1016/j.foodcont.2015.06.005]

Wittaya T. (2013). Influence of type and concentration of plasticizers on the properties of edible film from mung bean proteins. Kmitl Science and Technology Journal. 13: 51-58.

Yousuf B., Sun Y., Wu S. (2022). Lipid and lipid-containing composite edible coatings and films. Food Reviews International. 38: 574-597. [DOI: 10.1080/87559129. 2021.1876084]

Yu X., Yang Y., Liu Q., Jin Z., Jiao A. (2023). A hydroxypropyl methylcellulose/hydroxypropyl starch nanocomposite film reinforced with chitosan nanoparticles encapsulating cinnamon essential oil: preparation and characterization. International Journal of Biological Macromolecules. 242: 124605. [DOI: 10.1016/j.ijbiomac.2023.124605]

Zhang Y., Zhou L., Zhang C., Show P.L., Du A., Fu J.C., Ashokkumar V. (2020). Preparation and characterization of curdlan/polyvinyl alcohol/ thyme essential oil blending film and its application to chilled meat preservation. Carbohydrate Polymers. 247: 116670. [DOI: 10.1016/j.carbpol.2020.116670]

Zhao R., Guan W., Zhou X., Lao M., Cai L. (2022). The physiochemical and preservation properties of anthocyanidin/chitosan nanocomposite-based edible films containing cinnamon-perilla essential oil pickering nanoemulsions. LWT. 153: 112506. [DOI: 10.1016/j.lwt.2021. 112506]

Zhou Y., Wu X., Chen J., He J. (2021). Effects of cinnamon essential oil on the physical, mechanical, structural and thermal properties of cassava starch-based edible films. International Journal of Biological Macromolecules. 184: 574-583. [DOI: 10.1016/j.ijbiomac.2021.06.067]

Zubair M., Shahzad S., Hussain A., Pradhan R.A., Arshad M., Ullah A. (2022). Current trends in the utilization of essential oils for polysaccharide-and protein-derived food packaging materials. Polymers. 14: 1146. [DOI: 10.3390/polym14061146]

The increase in cinnamon essential oil concentration significantly improved tensile strength, WVTR, and antibacterial activity. The 8% cinnamon essential oil concentration was found to be the most effective, exhibiting the highest tensile strength (2.53 MPa), elongation (64.94%), WVTR (9.43 g/mm².day), and inhibition zones against E. coli (11.35 mm) and S. aureus (14.60 mm). A limitation of this study is the exclusive use of cinnamon essential oil; future research could investigate other essential oils or combinations to further enhance film properties. Additionally, the long-term stability and environmental impact of these films remain areas for future investigation. The practical applications of this research include the developing sustainable, antimicrobial food packaging, which could offer benefits consumers by reducing plastic waste and support local authorities in promoting environmentally friendly practices.

Author contributions

F.F. and D.K. designed the study; F.F. conducted the experimental work; F.F. and A.N. analyzed the data; F.F., D.K., and A.N. wrote the manuscript. All the authors read and approved the final manuscript.

Conflicts of interest

The authors have no conflict of interest.

Acknowledgments

The authors acknowledge the Directorate of Research, Technology, and Community Services (DRTPM), Ministry of Education, Culture, Research, and Technology of the Republic of Indonesia, for funding this research, through Fundamental-Regular Research with grant number: 060/E5/PG.02.00.PL/2024.

Funding

This research was supported by a grant from the Directorate of Research, Technology, and Community Service (DRTPM), Ministry of Education, Culture, Research, and Technology, Indonesia.

Ethical consideration

Not applicable.

References

Aleksanyan K.V. (2023). Polysaccharides for biodegradable packaging materials: past, present, and future (brief review). Polymers. 15: 451. [DOI: 10.3390/polym15020451]

American Society for Testing and Materials (ASTM). (2005). Standard test methods for water vapor transmission of materials. ASTM E96/E96M – 05. ASTM International, United States. URL: https://cdn.standards.iteh.ai/samples/41444/ee99c0b797cc4ae1a9f6d85416ae1302/ASTM-E96-E96M-05.pdf. Accessed 20 October 2024.

Azevedo V.M., Silva E.K., Pereira C.F.G., Da Costa J.M.G., Borges S.V. (2015). Whey protein isolate biodegradable films: influence of the citric acid and montmorillonite clay nanoparticles on the physical properties. Food Hydrocolloids. 43: 252-258. [DOI: 10.1016/j.foodhyd.2014.05.027]

Bahram S., Rezaei M., Soltani M., Kamali A., Ojagh S.M., Abdollahi M. (2014). Whey protein concentrate edible film activated with cinnamon essential oil. Journal of Food Processing and Preservation. 38: 1251-1258. [DOI: 10.1111/jfpp.12086]

Bandyopadhyay S., Saha N., Zandraa O., Pummerová M., Sáha P. (2020). Essential oil based PVP-CMC-BC-GG functional hydrogel sachet for ‘cheese’: its shelf life confirmed with anthocyanin (isolated from red cabbage) bio stickers. Foods. 9: 307. [DOI: 10.3390/foods9030307]

Beikzadeh S., Khezerlou A., Jafari S.M., Pilevar Z., Mortazavian A.M. (2020). Seed mucilages as the functional ingredients for biodegradable films and edible coatings in the food industry. Advances in Colloid and Interface Science. 280: 102164. [DOI: 10.1016/j.cis.2020.102164]

Chen H., Hu X., Chen E., Wu S., McClements D.J., Liu S., Li B., Li Y. (2016). Preparation, characterization, and properties of chitosan films with cinnamaldehyde nanoemulsions. Food Hydrocolloids. 61: 662-671. [DOI: 10.1016/j.foodhyd.2016.06.034]