Volume 12, Issue 1 (March 2025)

J. Food Qual. Hazards Control 2025, 12(1): 27-36 |

Back to browse issues page

Ethics code: Not applicable

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Das U, Bin Hasan M, Hussain T, Rahman A, Mahmood A, Marma S, et al . Physicochemical, Nutritional, and Sensory Attributes of High Fiber Fruit Leather of Red Dragon Fruit-Peel and Mango. J. Food Qual. Hazards Control 2025; 12 (1) :27-36

URL: http://jfqhc.ssu.ac.ir/article-1-1305-en.html

URL: http://jfqhc.ssu.ac.ir/article-1-1305-en.html

U. Das

, M.A. Bin Hasan

, M.A. Bin Hasan

, T. Hussain

, T. Hussain

, A. Rahman *

, A. Rahman *

, A. Mahmood

, A. Mahmood

, S. Marma

, S. Marma

, J. Tasnia

, J. Tasnia

, S. Akter

, S. Akter

, S. Barua

, S. Barua

, N.S. Fabia

, N.S. Fabia

, M.A. Bin Hasan

, M.A. Bin Hasan

, T. Hussain

, T. Hussain

, A. Rahman *

, A. Rahman *

, A. Mahmood

, A. Mahmood

, S. Marma

, S. Marma

, J. Tasnia

, J. Tasnia

, S. Akter

, S. Akter

, S. Barua

, S. Barua

, N.S. Fabia

, N.S. Fabia

One Health Institute, Chattogram Veterinary and Animal Sciences University, Chattogram 4225, Bangladesh , arneeloy@gmail.com

Full-Text [PDF 519 kb]

(778 Downloads)

| Abstract (HTML) (1994 Views)

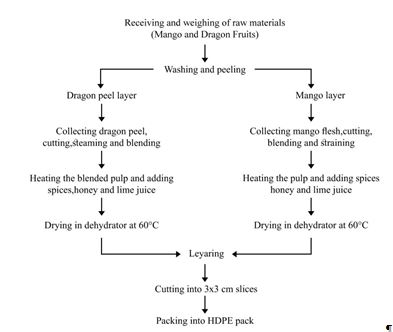

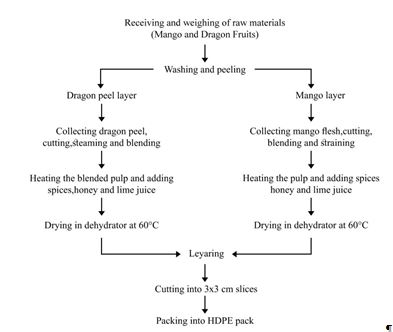

Figure 1: Process flow chart of dragon peel-mango leather production

Table 1: Physicochemical components of dragon peel-mango leather

Table 2: Proximate composition of dragon peel-mango leathers

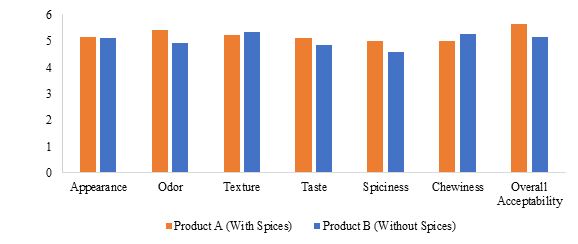

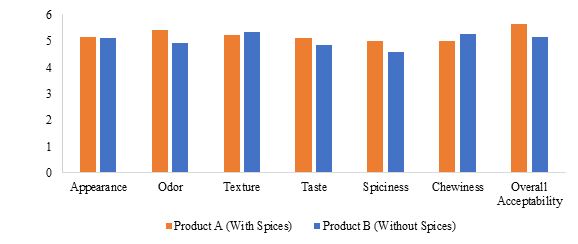

Figure 2: Comparative sensory evaluation of product A (with spices) and product B (without spices) based on appearance, odor, texture, taste, spiciness, chewiness, and overall acceptability.

Table 3: Comparison of sensory attributes between product A (with spices) and product B (without spices) with mean±Standard Deviation (SD) and statistical significance

Table 4: Microbiological features of dragon peel mango leather during four months of storage

Conclusion

Dragon peel, an underutilized by-product of fruit rich in fiber and its low in fat, offers significant dietary benefits. This study repurposes dragon fruit peel, a by-product typically discarded as waste, into a nutritious, functional snack with notable sensory appeal and health benefits. The physicochemical and nutritional analyses confirmed the product's suitability as a snack, providing significant dietary fiber, and antioxidant content while maintaining low moisture levels to ensure shelf stability. The product is entirely organic, as no synthesized materials were used. Moreover, the microbiological and sensory assessments validated the product's safety and acceptability over a four-month storage period. Notably, the spiced formulation stood out for its enhanced flavor and aroma, achieving higher sensory acceptability among panelists. This study contributes to the growing field of functional food innovation by addressing sustainability goals. However, the small sample size of sensory evaluation study might have constrained customer preference insights, and longer-term storage analyses could provide a more comprehensive understanding of stability under varying environmental conditions. Future research should explore other by-products, optimize formulations, conduct larger sensory evaluations, and improve packaging for improved shelf stability. Additionally, assessing economic feasibility and sustainability will further enhance the market viability of such innovations.

Author Contributions

U.D., M.A.B.H., T.H., A.R., and A.M. designed the study, conducted the experimental work, analyzed the data, and wrote the manuscript; S.M., J.T., S.A., and N.S.F. conducted the experimental work; S.M., and S.B. contributed to data analysis. All authors read and approved the final manuscript.

Acknowledgments

The authors are grateful to the authorities of Universiti Malaysia Terengganu for their support and allowing them to utilize the needed facilities for this research.

Conflicts of Interest

The authors declare that there is no conflict of interest.

Funding

This research received no specific grant from any funding agency in the public, commercial, or non-profit sectors.

Ethical consideration

Not applicable.

References

Amin G. (2012). Cumin. In: Peter K.V. (Editor). Handbook of herbs and spices. Woodhead Publishing, Sawston, Cambridge. pp: 250-259. [DOI: 10.1533/9780857095671.250]

Andrés-Bello A., Barreto-Palacios V., García-Segovia P., Mir-Bel J., Martínez-Monzó J. (2013). Effect of pH on color and texture of food products. Food Engineering Reviews. 5: 158-170. [DOI: 10.1007/s12393-013-9067-2]

Ann K.C., Suseno T.I.P., Utomo, A.R. (2012). Effect of red beet extract and gelatin concentration on physicochemical properties and organoleptic of marshmallow beet. Journal of Food Technology and Nutrition. 11: 28-36. [DOI: 10.33508/jtpg.v11i2.1472]. [Indonesian with English abstract]

Association of Official Analytical Chemists (AOAC). (1931). Official methods of analysis of the Association of Official Analytical Chemists (Volume 3). Association of Official Analytical Chemists. University of Michigan. URL: https://books.google.com/books/ about/Official_Methods_of_Analysis_of_the_Asso.html?id=6O7RAAAAMAAJ. Accessed 24 January 2025.

Azeredo H.M.C., Brito E.S., Moreira G.E.M., Farias V.L., Bruno L.M. (2006). Effect of drying and storage time on the physico‐chemical properties of mango leathers. International Journal of Food Science and Technology. 41: 635-638. [DOI: 10.1111/j.1365-2621.2005.01120.x]

Baloš M.Ž., Jakšić S., Popov N., Mihaljev Ž., Pelić D.L. (2019). Comparative study of water content in honey produced in different years. Archives of Veterinary Medicine. 12: 43-53. [DOI: 10.46784/e-avm.v12i1.42]

BeMiller J.N. (2017). Carbohydrate analysis. In: Nielsen S.S. (Editor). Food analysis. Springer, Cham. pp: 333-360. [DOI: 10.1007/978-3-319-45776-5_19]

Biswas O., Kandasamy P., Das S.K. (2022). Effect of dragon fruit peel powder on quality and acceptability of fish nuggets stored in a solar cooler (5±1° C). Journal of Food Science and Technology. 59: 3647-3658. [DOI: 10.1007/s13197-022-05377-5]

Chavan R.F., Jadhao V.G., Sakhale B.K. (2016). Studies on preparation of mango-sapota mixed fruit bar. South Asian Journal of Food Technology and Environment. 2: 361-365.

Cheok C.Y., Mohd Adzahan N., Abdul Rahman R., Zainal Abedin N.H., Hussain N., Sulaiman R., Chong G.H. (2018). Current trends of tropical fruit waste utilization. Critical Reviews in Food Science and Nutrition. 58: 335-361. [DOI: 10.1080/10408398. 2016.1176009]

Chima Ogbonna A., Izuchukwu Abuajah C., Glory, Ekpe E. (2013). A comparative study of the nutritive factors and sensory acceptance of juices from selected Nigerian fruits. Croatian Journal of Food Technology, Biotechnology and Nutrition. 8: 47-51.

Chumroenvidhayakul S., Thilavech T., Abeywardena M., Adisakwattana S. (2023). Dragon fruit peel waste (Hylocereus undatus) as a potential ingredient for reducing lipid peroxidation, dietary advanced glycation end products, and starch digestibility in cookies. Antioxidants. 12: 1002. [DOI: 10.3390/antiox12051002]

Daniel R.S., Osfar S., Dan Irfan H.D. (2014). Study of nutrient and anthocyanins pigments contents on three kinds of dragon fruit peel meal (hylocereus sp.) as feedstuff. URL: https://fapet.ub.ac.id/wp-content/uploads/ 2014/06/KAJIAN-KANDUNGAN- ZAT-MAKANAN- DAN-PIGMEN-ANTOSIANIN-TIGA- JENIS-KULIT-BUAH- NAGA-Hylocereus-Sp.-SEBAGAI- BAHAN-PAKAN-TERNAK.pdf. [Indonesian with English abstract]

Deepika D., Panja P. (2017). Enrichment on quality of aonla (Emblica officinalis G.) fruit bars by blending. Journal of Applied and Natural Science. 9: 162-166. [DOI:10.31018/jans.v9i1.1165]

Dharma A.S.B, Widodo F., Lo D. (2024). Physicochemical and sensory analysis of fruit leather made from orange peel and dragon fruit peel with isomalto-oligosaccharides as sucrose substitute. Food Science and Technology. 12: 62-70. [DOI: 10.13189/ fst.2024.120105]

Diamante L.M., Bai X., Busch J. (2014). Fruit leathers: method of preparation and effect of different conditions on qualities. International Journal of Food Science. 2014: 139890. [DOI: 10.1155/2014/139890]

Diop A., Méot J.-M., Léchaudel M., Chiroleu F., Ndiaye N.D., Mertz C., Cissé M., Chillet M. (2022). Impact of special drying schemes on color stability of mangoes with different maturity degrees. Foods. 11: 656. [DOI: 10.3390/foods11050656]

Downes F.P, Ito K. (2001). Compendium of methods for the microbiology examination of foods. 5th edition. American Public Health Association, Washington, DC. [DOI: 10.2105/MBEF.0222]

Ellong E.N., Adenet S., Rochefort K. (2015). Physicochemical, nutritional, organoleptic characteristics and food applications of four mango (Mangifera indica) varieties. Food and Nutrition Sciences. 6: 242-253. [DOI: 10.4236/fns.2015.62025]

Gondim J.A.M., Moura M.D.F.V., Dantas A.S., Medeiros R.L.S., Santos K.M. (2005). Centesimal composition and minerals in peels of fruits. Food Science and Technology. 25: 825-827. [DOI: 10.1590/S0101-20612005000400032]

Haytowitz D.B., Ahuja J.K.C., Wu X., Somanchi M., Nickle M., Nguyen Q.A., Roseland J.M., Williams J.R., Patterson K.Y., Li Y., Pehrsson P.R. (2019). USDA National nutrient database for standard reference, legacy release. Nutrient Data Laboratory, Beltsville Human Nutrition Research Center, ARS, USDA. [DOI: 10.15482/USDA.ADC/1529216]

Huang X., Hsieh F.H. (2005). Physical properties, sensory attributes, and consumer preference of pear fruit leather. Journal of Food Science. 70: E177-E186. [DOI: 10.1111/j.1365-2621.2005. tb07133.x]

Institute of Medicine and National Research Council (1985). An evaluation of the role of microbiological criteria for foods and food ingredients. National Academies Press, Washington, DC. [DOI: 10.17226/372]

Jain P.K., Jain P., Nema P.K. (2011). Quality of guava and papaya fruit pulp as influenced by blending ratio and storage period. American Journal of Technology 6: 507-512. [DOI: 10.3923/ajft.2011. 507.512]

Jalgaonkar K., Mahawar M.K., Bibwe B., Kannaujia P. (2022). Postharvest profile, processing and waste utilization of dragon fruit (Hylocereus spp.): a review. Food Reviews International. 38: 733-759. [DOI: 10.1080/87559129.2020.1742152]

Jamilah B., Shu C.E., Kharidah M., Dzulkily M.A., Noranizan A. (2011). Physico-chemical characteristics of red pitaya (Hylocereus polyrhizus) peel. International Food Research Journal. 18:279.

Javaria S., Marwat A., Nadeem M., Zerlasht M., Kareem A., Rubab I., Munir M. (2021). Development and physico-chemical characterization of apple-peach fruit leather. Pakistan Journal of Agricultural Research. 34: 254-493. [DOI: 10.17582/journal.pjar/2021/34.2.318.324]

Jethva K.R., Rathod S.R., Pargi A.S. (2023). Optimization of process variables for development of dragon fruit leather by using fruit peel as by-product utilization. The Pharma Innovation Journal.12: 1154-1159.

Kaleem M., Qazi I.M., Khan A., Khan M.A., Hussain I., Ayub M., Shinwari A.S., Shah F.N., Rehman A.U. (2017). Effect of different concentrations of sucrose and honey on the physiochemical and sensory properties of strawberry leather. Pakistan Journal of Scientific and Industrial Research, Series B: Biological Sciences. 60: 1-62.

Karel M., Anglea S., Buera P., Karmas R., Levi G., Roos Y. (1994). Stability-related transitions of amorphous foods. Thermochimica Acta. 246: 249-269. [DOI: 10.1016/0040-6031(94)80094-4]

Karmas E., Harris R.S. (2012). Nutritional evaluation of food processing. Springer Science and Business Media, Dordrecht, Netherlands. URL: https://books.google.com/books?id= ipOrBgAAQBAJ. Accessed 24 January 2025.

Kuria M.W., Matofari J.W., Nduko J.M. (2021). Physicochemical, antioxidant, and sensory properties of functional mango (Mangifera indica L.) leather fermented by lactic acid bacteria. Journal of Agriculture and Food Research. 6: 100206. [DOI: 10.1016/j.jafr.2021.100206]

Lakhanpal P., Vaidya D. (2015). Development and evaluation of honey based mango nectar. Journal of Food Science and Technology. 52: 1730-1735. [DOI: 10.1007/s13197-013-1122-8]

Lawless H.T., Heymann H. (2010). Sensory evaluation of food: principles and practices. 2nd edition. Springer, New York, NY. [DOI: 10.1007/978-1-4419-6488-5]

Le N.L. (2022). Functional compounds in dragon fruit peels and their potential health benefits: a review. International Journal of Food Science and Technology. 57: 2571-2580. [DOI: 10.1111/ijfs. 15111]

Lee G., Hsieh F. (2008). Thin-layer drying kinetics of strawberry fruit leather. Transactions of the ASABE. 51: 1699-1705. [DOI: 10.13031/2013.25292]

Leviana W., Paramita V. (2017). Effect of temperature on water content and water activity in material on turmeric (Curcuma longa) with tools electrical oven dryer. Metana. 13: 37-44. [Indonesian with English abstract]

Liaotrakoon W. (2013). Characterization of dragon fruit (Hylocereus spp.) components with valorization potential. PhD thesis, Ghent University, Belgium.

Liaotrakoon W., De Clercq N., Lewille B., Dewettinck K. (2012). Physicochemical properties, glass transition state diagram and colour stability of pulp and peel of two dragon fruit varieties (Hylocereus spp.) as affected by freeze-drying. International Food Research Journal. 19: 743-750.

Madusanka D.B.G., Sarananda K.H., Mahendran T., Hariharan G. (2016). Development of mixed fruit leather using five tropical fruits. 9th International Research Conference – KDU, Sri Lanka.

Maldonado-Celis M.E., Yahia E.M., Bedoya R., Landázuri P., Loango N., Aguillón J., Restrepo B., Guerrero Ospina J.C. (2019). Chemical composition of mango (Mangifera indica L.) fruit: nutritional and phytochemical compounds. Frontiers in Plant Science. 10: 1073. [DOI: 10.3389/fpls.2019.01073]

Mardhatilah D., Partha I.B.B., Hartati H. (2018). Influence of types of fatty materials and addition of sugar concentration on fruit leather quality from dragon fruit albedo (Hylocereus polyrhizus). IOP Conference Series: Earth and Environmental Science. 209: 012030. [DOI: 10.1088/1755-1315/209/1/012030]

Martínez S., López M., González-Raurich M., Bernardo Alvarez A. (2005). The effects of ripening stage and processing systems on vitamin C content in sweet peppers (Capsicum annuum L.). International Journal of Food Sciences and Nutrition. 56: 45-51. [DOI: 10.1080/09637480500081936]

Maskan A., Kaya S., Maskan M. (2002). Hot air and sun drying of grape leather (pestil). Journal of Food Engineering. 54: 81-88. [DOI: 10.1016/S0260-8774(01)00188-1]

Merrill A.L., Watt B.K. (1955). Energy value of foods: basis and derivation. US Department of Agriculture, USA.

Mieszczakowska-Frąc M., Celejewska K., Płocharski W. (2021). Impact of innovative technologies on the content of vitamin C and its bioavailability from processed fruit and vegetable products. Antioxidants. 10: 54. [DOI: 10.3390/antiox10010054]

National Center for Home Food Preservation (NCHFP). (2025). Drying. URL: https:// nchfp.uga.edu/how/dry/recipes/fruit-leathers/. Accessed 23 January 2025.

Naz R. (2012). Physical properties, sensory attributes and consumer preference of fruit leather. Pakistan Journal of Food Sciences. 22: 188-190.

Nollet L.M.L. (2004). Handbook of food analysis: volume 1: physical characterization and nutrient analysis. 2nd edition. CRC Press, Boca Raton, Florida. [DOI: 10.1201/9781482276459]

Offia-Olua B.I., Ekwunife O.A. (2015). Production and evaluation of the physico-chemical and sensory qualities of mixed fruit leather and cakes produced from apple (Musa Pumila), banana (Musa Sapientum), pineapple (Ananas Comosus). Nigerian Food Journal. 33: 22-28. [DOI: 10.1016/j.nifoj.2015.04.004]

Palve A., Shere P., Ghodke S., Kulthe A. (2020) Process Standardization for mango leather. Abhivruddhi Journal. 2: 81-83.

Purwandari U., Mojiono M., Putri N.W.K., Efendi M., Wijaya A. (2018). Storage stability of additive-free Salacca sp. fruit leather. Indonesian Journal of Agricultural Research. 1: 260-268. [DOI: 10.32734/injar.v1i3.495]

Putra I.G.A.M., Wangsaputri G.T., Putri M.R.M., Sutisna A.R. (2024). Characteristics of ice cream innovation based on soy whey and dragon fruit peel puree and its potential as a functional food. Journal of Functional Food and Nutraceutical, 6: 37-44. [DOI: 10.33555/jffn.v6i1.161]

Rabadán A., Nieto R., Bernabéu R. (2021). Food innovation as a means of developing healthier and more sustainable foods. Foods. 10: 2069. [DOI: 10.3390/foods10092069]

Radmard Ghadiri G., Kalbasi Oshtari A. (2011). Chemical and microbial properties of apple leather. Iranian Food Science and Technology Research Journal. 7. [DOI: 10.22067/ifstrj.v7i4. 11713]

Ranganna S. (1986). Handbook of analysis and quality control for fruit and vegetable products. Tata McGraw-Hill Education, New York, NY.

Robertson G.L. (2009). Food packaging and shelf life: a practical guide. 1st edition. CRC Press, Boca Raton, Florida. [DOI: 10.1201/ 9781420078459]

Šovljanski O., Travičić V., Tomić A., Vulić J., Šaponjac V.T., Ćetković G., Čanadanović-Brunet J. (2023). From agricultural waste to functional food products: an overview. In: Ramawat K., Mérillon J.M., Arora J. (editors). Agricultural waste: environmental impact, useful metabolites and energy production. Springer, Singapore. pp: 489-520. [DOI: 10.1007/978-981-19-8774-8_18]

Srinivas M.S., Jain S.K., Jain N.K., Lakhawat S.S., Kumar A., Jain H.K. (2020). A review on the preparation method of fruit leathers. International Journal of Current Microbiology and Applied Sciences. 9: 773-778. [DOI: 10.20546/ ijcmas.2020.905. 085]

Suparno, Fatmawati S.D., Fitriani N.R., Rahman A., Tarigan S.M.B., Faridawaty E., Sadono A., Gunawan W.B., Nurrezkytaku AY., Kumalawat D.A., Dewi R.S., Kumalawati D.A., et al. (2022). Effect of various red dragon fruit peel (Hylocereus polyrhizus) and yellow pumpkin (Cucurbita moschata) combinations and carrageenan proportion on the quality of the jam. Nutrición Clínica y Dietética Hospitalaria. 42: 182-189. [DOI: 10.12873/ 424suparno]

University of Rochester Medical Center (URMC). (2025a). Nutrition facts: spices, cumin seed, 1 tbsp. URL: https://www. urmc.rochester.edu/encyclopedia/content.aspx?contentid=02014-1&contenttypeid=76. Accessed 24 January 2025.

University of Rochester Medical Center (URMC). (2025b). Nutrition facts: spices, pepper, red or cayenne, 1 tsp. URL: https://www.urmc.rochester.edu/encyclopedia/content.aspx?contentid=02031-2&contenttypeid=76. Accessed 24 January 2025.

Food and Drug Administration (FDA). (2024). Bacteriological Analytical Manual (BAM). URL: https://www.fda.gov/food/ laboratory-methods-food/bacteriological-analytical-manual-bam. Accessed 24 January 2025.

Vijayanand P., Yadav A.R., Balasubramanyam N., Narasimham P. (2000). Storage stability of guava fruit bar prepared using a new process. LWT-Food Science and Technology. 33: 132-137. [DOI: 10.1006/fstl.1999.0627]

Wichienchot S., Jatupornpipat M., Rastall R.A. (2010). Oligosaccharides of pitaya (dragon fruit) flesh and their prebiotic properties. Food Chemistry. 120: 850-857. [DOI: 10.1016/ j.foodchem.2009.11.026]

Yang N., Galves C., Goncalves A.C.R., Chen J., Fisk I. (2020). Impact of capsaicin on aroma release: in vitro and in vivo analysis. Food Research International. 133: 109197. [DOI: 10.1016/ j.foodres.2020.109197]

Zahid H.F., Ranadheera C.S., Fang Z., Ajlouni S. (2021). Utilization of mango, apple and banana fruit peels as prebiotics and functional ingredients. Agriculture. 11: 584. [DOI: 10.3390/ agriculture11070584]

Zhuang Y., Zhang Y., Sun L. (2012). Characteristics of fibre‐rich powder and antioxidant activity of pitaya (Hylocereus undatus) peels. International Journal of Food Science and Technology. 47: 1279-1285. [DOI: 10.1111/j.1365-2621.2012.02971.x]

Full-Text: (2610 Views)

Physicochemical, Nutritional, and Sensory Attributes of High Fiber Fruit Leather of Red Dragon Fruit-Peel and Mango

U. Das 1, M.A. Bin Hasan 1, T. Hussain 2, A. Rahman 2[*]* , A. Mahmood 3, S. Marma 1,

J. Tasnia 2, S. Akter 1, S. Barua 1, N.S. Fabia 1

1. Department of Applied Food Science and Nutrition, Chattogram Veterinary and Animal Sciences University, Chattogram 4225, Bangladesh

2. One Health Institute, Chattogram Veterinary and Animal Sciences University, Chattogram 4225, Bangladesh

3. Faculty of Fisheries and Food Science, Universiti Malaysia Terengganu, 21300 Kuala Nerus Terengganu, Malaysia

U. Das 1, M.A. Bin Hasan 1, T. Hussain 2, A. Rahman 2[*]*

J. Tasnia 2, S. Akter 1, S. Barua 1, N.S. Fabia 1

1. Department of Applied Food Science and Nutrition, Chattogram Veterinary and Animal Sciences University, Chattogram 4225, Bangladesh

2. One Health Institute, Chattogram Veterinary and Animal Sciences University, Chattogram 4225, Bangladesh

3. Faculty of Fisheries and Food Science, Universiti Malaysia Terengganu, 21300 Kuala Nerus Terengganu, Malaysia

HIGHLIGHTS

- High fiber, low energy entirely organic fruit leather as synthetic ingredients were absent.

- Honey slightly reduced the total soluble solids due to its water content, affecting texture.

- Spices significantly influenced the taste and aroma of the fruit leather.

| Article type Original article |

ABSTRACT Background: The growing demand for sustainable and health-conscious foods has led to innovative uses of fruit by-products. Dragon fruit peel, often discarded, is high in fiber and antioxidants, while mango pulp enhances taste and nutritional value. This study focused on developing a fiber-rich, sustainable fruit leather, assessing its physicochemical, nutritional, and sensory properties to evaluate its potential for commercialization. Methods: Two fruit leather formulations were prepared: one with spices and one without. Their physicochemical properties including pH, total soluble solids (°Brix), water activity, and ascorbic acid content along with proximate composition (protein, fiber, fat, ash, and carbohydrate content) were assessed using standard methods. Sensory evaluation was conducted with 30 untrained panelists (15 male and 15 female) using a seven-point hedonic scale to assess appearance, odor, texture, taste, spiciness, chewiness, and overall acceptability. Quality parameters such as color, flavor, texture, and taste were also evaluated at 30-day intervals for four months by five trained panelists. Statistical analysis was performed using one-way ANOVA, with results reported as mean±Standard Deviation, using Minitab v21, with statistical significance set at p<0.05. Results: The spiced formulation showed a pH of 4.03, total soluble solids of 35.2 °Brix, water activity of 0.641, and ascorbic acid content of 58.5 mg/100 g. Proximate analysis revealed moisture content of 13.76%, crude protein of 2.74%, crude fiber of 33.91%, crude fat of 0.54%, ash of 3.74%, and carbohydrate content of 20.58%, with an energy value of 98.14 kcal/100 g. Sensory evaluation indicated a preference for the spiced version due to enhanced flavor and aroma, achieving higher acceptability scores. Conclusion: This research highlights the potential of repurposing dragon fruit peel into a commercially viable, high-fiber snack, contributing to waste reduction and functional food innovation. Additionally, mango further enhances the product’s sensory appeal and nutritional profile. © 2025, Shahid Sadoughi University of Medical Sciences. This is an open access article under the Creative Commons Attribution 4.0 International License. |

|

| Keywords Mangifera Dietary Fiber Dragon Fruit Cactus Food. |

||

| Article history Received: 15 Dec 2024 Revised: 27 Feb 2025 Accept: 20 Mar 2025 |

||

| Abbreviations WA=Water Activity TSC=Total Sugar Content |

To cite: Das U., Bin Hasan M.A., Hussain T., Rahman A., Mahmood A., Marma S., Tasnia J., Akter S., Barua S., Fabia N.S. (2025). Physicochemical, nutritional, and sensory attributes of high fiber fruit leather of red dragon fruit-peel and mango. Journal of Food Quality and Hazards Control. 12: 27-36.

Introduction

Introduction

The food industry is increasingly focusing on developing sustainable, healthy products to meet the rising consumer demand for functional foods (Rabadán et al., 2021). Over recent decades, this focus has paralleled a notable global shift toward healthier eating habits, where fruits have become essential components of dietary patterns. Innovative products like fruit leather illustrate this trend, offering a low-calorie, high-fiber snack option that aligns with health-conscious lifestyles (Diamante et al., 2014).

Fruit leather is a dehydrated, chewy confection made from fruit pulp, puree, or juice, often combined with sweeteners or other natural additives (Maskan et al., 2002; Srinivas et al., 2020). It has gained popularity as a nutritious and convenient snack due to its prolonged shelf-life, appealing taste, and concentration of essential nutrients such as vitamins, minerals, and bioactive compounds (Diamante et al., 2014). Fruit leather can be enjoyed as a snack or incorporated into various food preparations, offering a low-calorie option with fewer than 100 kcals per serving, making it a healthier alternative to many traditional snacks (Huang and Hsieh, 2005).

Dragon fruit (Selenicereus undatus), a tropical and subtropical fruit known for its vibrant appearance and subtle sweetness, has gained global popularity for its high antioxidant and fiber content (Wichienchot et al., 2010). On average, one hectare of dragon fruit plantations produces 50 tons of fresh fruit, with the peels accounting for 20-40% of the total weight (Liaotrakoon et al., 2012). These peels, often discarded as waste especially in beverage production industries pose environmental challenges (Jalgaonkar et al., 2022; Jamilah et al., 2011). Long-term disposal contributes to greenhouse gas emissions during decomposition and creates breeding grounds for pests, bacteria, and mice, potentially spreading diseases (Cheok et al., 2018). However, dragon fruit peel has captured the attention of researchers, driven by the rising demand for natural, health-enhancing bioactive compounds among consumers. Notably, the peel of dragon fruit, often considered waste, harbors significant nutritional potential, particularly as a source of high dietary fiber, antioxidant, phenolic compounds, and natural pigments like Betalains (Gondim et al., 2005; Le, 2022). On the other hand, Mango (Mangifera indica), often regarded as the "king of fruits", is renowned for its rich flavor and abundant nutrients, including vitamin C, provitamin A, polyphenols, and dietary fiber (Maldonado-Celis et al., 2019), which makes mangoes perfect for producing a leather that aligns with consumer preferences for natural and additive-free snacks.

Recent studies have highlighted the potential of dragon fruit peel in various applications, including fruit leather production (Šovljanski et al., 2023), and its incorporation into cookies to reduce lipid peroxidation (Chumroenvidhayakul et al., 2023). However, the combination of dragon fruit peel with other tropical fruits, such as mango, for innovative food products like fruit leather remains underexplored. Our study addresses this gap by developing a mango-dragon fruit peel leather, aiming to enhance nutritional value and promote sustainable by-product utilization. Additionally, this study examines the physicochemical, nutritional, and sensory attributes of the developed fruit leather to assess its potential as a commercially viable product.

Materials and methods

Raw materials collection

The development of the fruit leather was carried out at the food processing laboratory of the Faculty of Fisheries and Food Science at University Malaysia Terengganu. Dragon fruit and mango were purchased from the local market of Terengganu City (Malaysia). The dragon fruits were well ripened with a pink color, and both ripened and unripened mangoes were purchased for this experiment. Uniformity in size and color was ensured during the fruits selection, as well as resistance to disease and infection. The other four major ingredients, lemon, honey, cayenne pepper powder, and ground cumin powder, were collected from a super shop in Terengganu City of Malaysia.

Preparing dragon peel-mango leather

The preparation of both the dragon peel and mango pulp layer began with thoroughly washing the fruits, followed by peeling them (Figure 1). The peels and pulps were then cut into smaller pieces and steamed to soften them. After steaming, the dragon peels were blended and strained to produce a smooth dragon peel puree, and a similar process was applied to obtain a smooth, fiber-free mango pulp puree. Both the dragon peel and mango pulp puree were combined with spices, lime, and honey, separately. Then, the mixtures were cooked separately with continuous stirring until the desired texture and consistency were achieved. After preparing the dragon peel puree and mango puree, both purees were poured into trays in thick layers. The purees were dried in a hot air oven at 60 °C for 6 to 8 h. Afterwards, the trays were taken out of the hot air oven and allowed to cool. A layer of mango leather was placed between two layers of dragon fruit leather. Finally, the three-layered fruit leather was cut into rectangular shapes and packed at room temperature (NCHFP, 2025).

Fruit leather is a dehydrated, chewy confection made from fruit pulp, puree, or juice, often combined with sweeteners or other natural additives (Maskan et al., 2002; Srinivas et al., 2020). It has gained popularity as a nutritious and convenient snack due to its prolonged shelf-life, appealing taste, and concentration of essential nutrients such as vitamins, minerals, and bioactive compounds (Diamante et al., 2014). Fruit leather can be enjoyed as a snack or incorporated into various food preparations, offering a low-calorie option with fewer than 100 kcals per serving, making it a healthier alternative to many traditional snacks (Huang and Hsieh, 2005).

Dragon fruit (Selenicereus undatus), a tropical and subtropical fruit known for its vibrant appearance and subtle sweetness, has gained global popularity for its high antioxidant and fiber content (Wichienchot et al., 2010). On average, one hectare of dragon fruit plantations produces 50 tons of fresh fruit, with the peels accounting for 20-40% of the total weight (Liaotrakoon et al., 2012). These peels, often discarded as waste especially in beverage production industries pose environmental challenges (Jalgaonkar et al., 2022; Jamilah et al., 2011). Long-term disposal contributes to greenhouse gas emissions during decomposition and creates breeding grounds for pests, bacteria, and mice, potentially spreading diseases (Cheok et al., 2018). However, dragon fruit peel has captured the attention of researchers, driven by the rising demand for natural, health-enhancing bioactive compounds among consumers. Notably, the peel of dragon fruit, often considered waste, harbors significant nutritional potential, particularly as a source of high dietary fiber, antioxidant, phenolic compounds, and natural pigments like Betalains (Gondim et al., 2005; Le, 2022). On the other hand, Mango (Mangifera indica), often regarded as the "king of fruits", is renowned for its rich flavor and abundant nutrients, including vitamin C, provitamin A, polyphenols, and dietary fiber (Maldonado-Celis et al., 2019), which makes mangoes perfect for producing a leather that aligns with consumer preferences for natural and additive-free snacks.

Recent studies have highlighted the potential of dragon fruit peel in various applications, including fruit leather production (Šovljanski et al., 2023), and its incorporation into cookies to reduce lipid peroxidation (Chumroenvidhayakul et al., 2023). However, the combination of dragon fruit peel with other tropical fruits, such as mango, for innovative food products like fruit leather remains underexplored. Our study addresses this gap by developing a mango-dragon fruit peel leather, aiming to enhance nutritional value and promote sustainable by-product utilization. Additionally, this study examines the physicochemical, nutritional, and sensory attributes of the developed fruit leather to assess its potential as a commercially viable product.

Materials and methods

Raw materials collection

The development of the fruit leather was carried out at the food processing laboratory of the Faculty of Fisheries and Food Science at University Malaysia Terengganu. Dragon fruit and mango were purchased from the local market of Terengganu City (Malaysia). The dragon fruits were well ripened with a pink color, and both ripened and unripened mangoes were purchased for this experiment. Uniformity in size and color was ensured during the fruits selection, as well as resistance to disease and infection. The other four major ingredients, lemon, honey, cayenne pepper powder, and ground cumin powder, were collected from a super shop in Terengganu City of Malaysia.

Preparing dragon peel-mango leather

The preparation of both the dragon peel and mango pulp layer began with thoroughly washing the fruits, followed by peeling them (Figure 1). The peels and pulps were then cut into smaller pieces and steamed to soften them. After steaming, the dragon peels were blended and strained to produce a smooth dragon peel puree, and a similar process was applied to obtain a smooth, fiber-free mango pulp puree. Both the dragon peel and mango pulp puree were combined with spices, lime, and honey, separately. Then, the mixtures were cooked separately with continuous stirring until the desired texture and consistency were achieved. After preparing the dragon peel puree and mango puree, both purees were poured into trays in thick layers. The purees were dried in a hot air oven at 60 °C for 6 to 8 h. Afterwards, the trays were taken out of the hot air oven and allowed to cool. A layer of mango leather was placed between two layers of dragon fruit leather. Finally, the three-layered fruit leather was cut into rectangular shapes and packed at room temperature (NCHFP, 2025).

Figure 1: Process flow chart of dragon peel-mango leather production

Assessment of physicochemical components

The moisture level in the mixed fruit leather was assessed using the technique outlined by Ranganna (1986). The pH of the mixed fruit leather was measured using a pH meter (Model 3505, JENWAY, United Kingdom). Total soluble solids (°Brix) were determined using a refractometer (Atago PAL-1, Japan) with results expressed as a percentage of soluble solids (°Brix). The ascorbic acid (vitamin C) content (mg/100 g) was evaluated using 2,6-dichlorophenol indophenol dye. Water Activity (WA) was evaluated using a hygrometric method with an WA meter (AQUALAB 4TE, United States of America). All these analyses were performed following the standard protocols outlined by AOAC (1931).

Proximate analysis

Following the standard procedure outlined by the Association of Official Analytical Chemists (AOAC), the proximate analysis was conducted, taking into account the sample's moisture, crude protein, crude fiber, crude fat, total ash, and carbohydrate (AOAC, 1931). The total carbohydrate was calculated by difference (BeMiller, 2017). The energy content of the fruit was measured in kcal per 100 g, calculated by multiplying the values for crude protein, lipids, and carbohydrates by the respective recommended factors of four, nine, and four. All analyses were carried out in triplicate (Merrill and Watt, 1955).

Sensory evaluation

A consumer acceptance study was conducted to evaluate the sensory attributes of the developed fruit leather. Fifteen male and 15 female students expressed willingness and interest to participate in the test as panelists were randomly recruited. Samples of two fruit leathers (with and without spices) in identical containers, each coded with a different three-digit random number, were placed on a tray and served to the panelists. To determine their degree to which they liked or disliked the products, the evaluators assessed the acceptability of the fruit leather in terms of appearance, odor, texture, taste, spiciness, chewiness, and overall acceptability using a structured seven-point hedonic scale (Lawless and Heymann, 2010). Plain water was provided for panelists to rinse their mouths before testing each sample. Standard fluorescent light was used during the evaluation. The study also ensured that the anonymity/confidentiality of the sensory evaluation was reported.

Microbiological study

The fruit leather was packaged in High-Density Poly Ethylene (HDPE) bags and stored under ambient conditions (20-25 °C, 50-60% relative humidity) to evaluate shelf-life over a period of four months. The microbial analysis focused on mesophilic aerobes, coliforms, yeast, and mold, which are known to influence food quality (Radmard Ghadiri and Kalbasi Oshtari, 2011; Robertson, 2009). Microbial load was determined following the guidelines of Downes and Ito (2001). A one g sample of fruit leather was homogenized (Stomacher 400, Seward Ltd., UK) in nine ml of sterile distilled water. Serial dilutions (10-3, 10-4, and 10-5) were prepared by transferring one ml of the diluted sample into subsequent test tubes containing nine ml of distilled water (FDA, 2024). One ml of the diluted sample was used for the pour plate method on Plate Count Agar (PCA, Bio Merieux, Malaysia) to determine mesophilic counts. Meanwhile, 0.1 ml was spread using the surface plate method on Yeast Glucose Chloramphenicol (YGC, Bio Merieux, Malaysia) agar for yeast and mold counts. Both were incubated at 30 °C under relevant atmospheric conditions for 48 h. Colony counts were performed using a manual colony counter, with each measurement conducted in triplicate to ensure accuracy.

Quality parameters

The color, flavor, texture, taste, and overall acceptability were observed at 30 day intervals during storage for 4 months. These attributes were evaluated by five trained sensory panelists on a seven-point hedonic scale rating (Lawless and Heymann, 2010).

Statistical analysis

The experimental data were collected in triplicate, and results were reported as mean±Standard Deviation (SD). Statistical analysis was performed using one-way Analysis of Variance (ANOVA). All analyses were conducted using Minitab 21 (Minitab LLC, State College, PA, USA). A significance level of p<0.05 was considered statistically significant.

Results and discussion

Physicochemical analysis

pH is a crucial characteristic, which is closely linked to acidity. This quality influences the taste, flavor, and shelf life of dried food products (Andrés-Bello et al., 2013). The information shown in Table 1 indicates the pH of fruit leather without spices is 4.17±0.05, which is slightly higher than 4.03±0.05 for the formulation with spices. These findings demonstrate that the leather samples were moderately acidic, enhancing the product's flavor and potentially extending their shelf-life. Previous studies reported an average pH of 3.82 for dragon fruit leather, consistent with the moderately acidic nature of the samples in this study (Jethva et al., 2023). Another study found that the pH of dragon fruit skin (albedo) leather had a mean value of 3.64, slightly lower than that of the leather samples in this study (Mardhatilah et al., 2018). Additionally, the mango leather from the Ngowe variety had a pH of 4.09, further supporting the trend of moderate acidity in fruit leather products (Kuria et al., 2021).

The Total Sugar Content (TSC) of the fruit leather without spices was measured to be 35.2±0.3 °Brix, which is the same as the formulation with spices. This is because these spices contribute negligible amounts of sugar to the final product. The TSC of 35.2 °Brix found in this study is consistent with typical values for fruit leather products. For example, dragon fruit peel (albedo) leather and mixed fruit leather were found to have higher TSC values of 45.6 °Brix and 58.8 °Brix, respectively (Madusanka et al., 2016; Mardhatilah et al., 2018). The fruit leather in this study incorporated honey, which explain the relatively lower TSC compared to the other studies as honey adds soluble solids and sweetness but contributes slightly less TSC due to its water content (Baloš et al., 2019). Another study reported a lower TSC content of 20 °Brix of a mixed fruit leather produced from banana–pineapple–apple (Offia-Olua and Ekwunife, 2015).

WA is a critical parameter influencing the stability, quality, and safety of food products. This characteristic is essential as microorganisms, including bacteria and yeast, require water to support their growth and survival (Leviana and Paramita, 2017). The WA value of the fruit leather without spices in this study was measured at 0.629±0.006 and for the ones with spices was at 0.641±0.008, which falls within the range that ensures microbial stability and extends their shelf-life. The WA value observed in this study aligns closely with findings from previous research. For instance, a study reported that an WA value near 0.62 can effectively stabilize fruit leather products, preventing microbial spoilage for up to 6 months without the use of preservatives (Azeredo et al., 2006). Similarly, another study on fruit leather made from orange peel and dragon fruit peel reported WA values ranging from 0.660±0.020 to 0.712±0.003 (Dharma et al., 2024).

Ascorbic acid, commonly referred to as vitamin C, is an essential nutrient that has a key role in enhancing iron absorption and aiding collagen production, both of which are crucial for overall health (Chima Ogbonna et al., 2013). The levels of ascorbic acid in fruit-based products can differ significantly based on the fruit varieties and their ripeness (Haytowitz et al., 2019; Martínez et al., 2005). In this analysis, the ascorbic acid level in the fruit leather without spices was measured at 55.51±0.85 mg/100 g, while an ascorbic acid content of 58.5±1.0 mg/100 g was measured for the formulation with spices. This study’s findings reveal a higher ascorbic acid level compared to some other fruit leathers. For example, a research regarding mixed fruit leathers made from banana-pineapple and apple showed ascorbic acid levels of 22.33±0.06 mg/100 g, whereas a study on apple-peach fruit leather indicated a slightly elevated content of 46.6±0.06 mg/100 g (Javaria et al., 2021; Offia-Olua and Ekwunife, 2015). These variations in ascorbic acid content are result from the particular fruit mixtures used and the processing methods employed (Mieszczakowska-Frąc et al., 2021).

The moisture level in the mixed fruit leather was assessed using the technique outlined by Ranganna (1986). The pH of the mixed fruit leather was measured using a pH meter (Model 3505, JENWAY, United Kingdom). Total soluble solids (°Brix) were determined using a refractometer (Atago PAL-1, Japan) with results expressed as a percentage of soluble solids (°Brix). The ascorbic acid (vitamin C) content (mg/100 g) was evaluated using 2,6-dichlorophenol indophenol dye. Water Activity (WA) was evaluated using a hygrometric method with an WA meter (AQUALAB 4TE, United States of America). All these analyses were performed following the standard protocols outlined by AOAC (1931).

Proximate analysis

Following the standard procedure outlined by the Association of Official Analytical Chemists (AOAC), the proximate analysis was conducted, taking into account the sample's moisture, crude protein, crude fiber, crude fat, total ash, and carbohydrate (AOAC, 1931). The total carbohydrate was calculated by difference (BeMiller, 2017). The energy content of the fruit was measured in kcal per 100 g, calculated by multiplying the values for crude protein, lipids, and carbohydrates by the respective recommended factors of four, nine, and four. All analyses were carried out in triplicate (Merrill and Watt, 1955).

Sensory evaluation

A consumer acceptance study was conducted to evaluate the sensory attributes of the developed fruit leather. Fifteen male and 15 female students expressed willingness and interest to participate in the test as panelists were randomly recruited. Samples of two fruit leathers (with and without spices) in identical containers, each coded with a different three-digit random number, were placed on a tray and served to the panelists. To determine their degree to which they liked or disliked the products, the evaluators assessed the acceptability of the fruit leather in terms of appearance, odor, texture, taste, spiciness, chewiness, and overall acceptability using a structured seven-point hedonic scale (Lawless and Heymann, 2010). Plain water was provided for panelists to rinse their mouths before testing each sample. Standard fluorescent light was used during the evaluation. The study also ensured that the anonymity/confidentiality of the sensory evaluation was reported.

Microbiological study

The fruit leather was packaged in High-Density Poly Ethylene (HDPE) bags and stored under ambient conditions (20-25 °C, 50-60% relative humidity) to evaluate shelf-life over a period of four months. The microbial analysis focused on mesophilic aerobes, coliforms, yeast, and mold, which are known to influence food quality (Radmard Ghadiri and Kalbasi Oshtari, 2011; Robertson, 2009). Microbial load was determined following the guidelines of Downes and Ito (2001). A one g sample of fruit leather was homogenized (Stomacher 400, Seward Ltd., UK) in nine ml of sterile distilled water. Serial dilutions (10-3, 10-4, and 10-5) were prepared by transferring one ml of the diluted sample into subsequent test tubes containing nine ml of distilled water (FDA, 2024). One ml of the diluted sample was used for the pour plate method on Plate Count Agar (PCA, Bio Merieux, Malaysia) to determine mesophilic counts. Meanwhile, 0.1 ml was spread using the surface plate method on Yeast Glucose Chloramphenicol (YGC, Bio Merieux, Malaysia) agar for yeast and mold counts. Both were incubated at 30 °C under relevant atmospheric conditions for 48 h. Colony counts were performed using a manual colony counter, with each measurement conducted in triplicate to ensure accuracy.

Quality parameters

The color, flavor, texture, taste, and overall acceptability were observed at 30 day intervals during storage for 4 months. These attributes were evaluated by five trained sensory panelists on a seven-point hedonic scale rating (Lawless and Heymann, 2010).

Statistical analysis

The experimental data were collected in triplicate, and results were reported as mean±Standard Deviation (SD). Statistical analysis was performed using one-way Analysis of Variance (ANOVA). All analyses were conducted using Minitab 21 (Minitab LLC, State College, PA, USA). A significance level of p<0.05 was considered statistically significant.

Results and discussion

Physicochemical analysis

pH is a crucial characteristic, which is closely linked to acidity. This quality influences the taste, flavor, and shelf life of dried food products (Andrés-Bello et al., 2013). The information shown in Table 1 indicates the pH of fruit leather without spices is 4.17±0.05, which is slightly higher than 4.03±0.05 for the formulation with spices. These findings demonstrate that the leather samples were moderately acidic, enhancing the product's flavor and potentially extending their shelf-life. Previous studies reported an average pH of 3.82 for dragon fruit leather, consistent with the moderately acidic nature of the samples in this study (Jethva et al., 2023). Another study found that the pH of dragon fruit skin (albedo) leather had a mean value of 3.64, slightly lower than that of the leather samples in this study (Mardhatilah et al., 2018). Additionally, the mango leather from the Ngowe variety had a pH of 4.09, further supporting the trend of moderate acidity in fruit leather products (Kuria et al., 2021).

The Total Sugar Content (TSC) of the fruit leather without spices was measured to be 35.2±0.3 °Brix, which is the same as the formulation with spices. This is because these spices contribute negligible amounts of sugar to the final product. The TSC of 35.2 °Brix found in this study is consistent with typical values for fruit leather products. For example, dragon fruit peel (albedo) leather and mixed fruit leather were found to have higher TSC values of 45.6 °Brix and 58.8 °Brix, respectively (Madusanka et al., 2016; Mardhatilah et al., 2018). The fruit leather in this study incorporated honey, which explain the relatively lower TSC compared to the other studies as honey adds soluble solids and sweetness but contributes slightly less TSC due to its water content (Baloš et al., 2019). Another study reported a lower TSC content of 20 °Brix of a mixed fruit leather produced from banana–pineapple–apple (Offia-Olua and Ekwunife, 2015).

WA is a critical parameter influencing the stability, quality, and safety of food products. This characteristic is essential as microorganisms, including bacteria and yeast, require water to support their growth and survival (Leviana and Paramita, 2017). The WA value of the fruit leather without spices in this study was measured at 0.629±0.006 and for the ones with spices was at 0.641±0.008, which falls within the range that ensures microbial stability and extends their shelf-life. The WA value observed in this study aligns closely with findings from previous research. For instance, a study reported that an WA value near 0.62 can effectively stabilize fruit leather products, preventing microbial spoilage for up to 6 months without the use of preservatives (Azeredo et al., 2006). Similarly, another study on fruit leather made from orange peel and dragon fruit peel reported WA values ranging from 0.660±0.020 to 0.712±0.003 (Dharma et al., 2024).

Ascorbic acid, commonly referred to as vitamin C, is an essential nutrient that has a key role in enhancing iron absorption and aiding collagen production, both of which are crucial for overall health (Chima Ogbonna et al., 2013). The levels of ascorbic acid in fruit-based products can differ significantly based on the fruit varieties and their ripeness (Haytowitz et al., 2019; Martínez et al., 2005). In this analysis, the ascorbic acid level in the fruit leather without spices was measured at 55.51±0.85 mg/100 g, while an ascorbic acid content of 58.5±1.0 mg/100 g was measured for the formulation with spices. This study’s findings reveal a higher ascorbic acid level compared to some other fruit leathers. For example, a research regarding mixed fruit leathers made from banana-pineapple and apple showed ascorbic acid levels of 22.33±0.06 mg/100 g, whereas a study on apple-peach fruit leather indicated a slightly elevated content of 46.6±0.06 mg/100 g (Javaria et al., 2021; Offia-Olua and Ekwunife, 2015). These variations in ascorbic acid content are result from the particular fruit mixtures used and the processing methods employed (Mieszczakowska-Frąc et al., 2021).

Table 1: Physicochemical components of dragon peel-mango leather

| Physicochemical components | With spices (Mean±SD) | Without spices (Mean±SD) |

| pH | 4.03±0.05 | 4.17±0.05 |

| Total Sugar Content (TSC) (°Bx) | 35.2±0.3 | 35.2±0.3 |

| Water Activity (WA) | 0.641±0.008 | 0.629±0.006 |

| Ascorbic acid content (mg/100 g) | 58.5±1.0 | 55.51±0.85 |

°Bx=Degrees Brix

Proximate analysis

Proximate analysis

The proximate composition of fruit leather with or without spices is presented in Table 1. There were few significant differences between the two formulations, with the majority of parameters having similar mean and SD ranges.

The moisture content of the fruit leather with spices was 13.76±0.75%, slightly higher than the formulation without spices (13.70±0.70%). These values are within the acceptable range for fruit leathers, as low moisture levels (below 15%) are essential for preventing microbial growth, unwanted reactions such as sugar crystallization, nonenzymatic browning, flavor losses, lipid oxidation, and ensuring a longer shelf-life (Karel et al., 1994; Maskan et al., 2002). The negligible difference suggests that the addition of spices did not significantly affect moisture retention during drying.

The crude protein content (dry basis %) was 2.74±0.19% with spices and 2.72±0.18% without spices. These values are consistent with the expected range for fruit leathers, typically between 1 and 3% (Chavan et al., 2016; Deepika and Panja, 2017). The relatively low protein content aligns with the primary composition of fruit-based ingredients, which are not naturally protein-rich. Dragon fruit peel and mango, the main components of this leather, are known to contain only 2-3% protein and 0.5-1% protein, respectively (Suparno et al., 2022; Maldonado-Celis et al., 2019).

The crude fiber content (dry basis %) was 33.91±2.67% in both formulations. This high fiber content reflects the significant contribution of dragon fruit peel, which is known to contain 55-82% insoluble dietary fiber and 21-39% soluble fiber (Jamilah et al., 2011; Le, 2022; Zhuang et al., 2012). This value exceeds the crude fiber content typically reported for mango leather (Palve et al., 2020) and dragon fruit leather (Mardhatilah et al., 2018).

The crude fat content (dry basis %) was 0.54±0.03% with spices and 0.52±0.03% without spices. Fruit leathers are widely regarded as nutritious snack options, characterized by their naturally high fiber and carbohydrate content while being low in fat (Lee and Hsieh, 2008). The low-fat content is consistent with the composition of the primary ingredients (mango and dragon fruit peel), which are naturally low in fat (Daniel et al., 2014; Maldonado-Celis et al., 2019). The slight increase in fat content in the spiced version may be attributed to trace amounts of fat in cumin and cayenne powder (URMC, 2025a).

The total ash content (dry basis %) was 3.74±0.41% in the spiced version and 3.70±0.38% in the spice-free version. Ash content reflects the total mineral content of the leather and is influenced by the ash content of dragon fruit peel and mango (Biswas et al., 2022; Maldonado-Celis et al., 2019). The small difference indicates minimal contribution from the added spices (URMC, 2025b).

The total carbohydrate content (dry basis %) was 20.58±1.52% with spices and 20.55±1.50% without spices. The similar values confirm that spices had little to no effect on the carbohydrate profile of the leather. The carbohydrate content predominantly originates from mango and honey, as reported in similar fruit and honey-based nectar studies (Lakhanpal and Vaidya, 2015).

The calculated energy value was 98.14±1.93 kcal/100 g with spices and 97.76±1.8 kcal/100 g without spices. These values are lower than typical fruit leathers due to the high fiber and low-fat composition of the product. Similar finding has been reported where high-fiber components lead to lower caloric content (Zahid et al., 2021).

The moisture content of the fruit leather with spices was 13.76±0.75%, slightly higher than the formulation without spices (13.70±0.70%). These values are within the acceptable range for fruit leathers, as low moisture levels (below 15%) are essential for preventing microbial growth, unwanted reactions such as sugar crystallization, nonenzymatic browning, flavor losses, lipid oxidation, and ensuring a longer shelf-life (Karel et al., 1994; Maskan et al., 2002). The negligible difference suggests that the addition of spices did not significantly affect moisture retention during drying.

The crude protein content (dry basis %) was 2.74±0.19% with spices and 2.72±0.18% without spices. These values are consistent with the expected range for fruit leathers, typically between 1 and 3% (Chavan et al., 2016; Deepika and Panja, 2017). The relatively low protein content aligns with the primary composition of fruit-based ingredients, which are not naturally protein-rich. Dragon fruit peel and mango, the main components of this leather, are known to contain only 2-3% protein and 0.5-1% protein, respectively (Suparno et al., 2022; Maldonado-Celis et al., 2019).

The crude fiber content (dry basis %) was 33.91±2.67% in both formulations. This high fiber content reflects the significant contribution of dragon fruit peel, which is known to contain 55-82% insoluble dietary fiber and 21-39% soluble fiber (Jamilah et al., 2011; Le, 2022; Zhuang et al., 2012). This value exceeds the crude fiber content typically reported for mango leather (Palve et al., 2020) and dragon fruit leather (Mardhatilah et al., 2018).

The crude fat content (dry basis %) was 0.54±0.03% with spices and 0.52±0.03% without spices. Fruit leathers are widely regarded as nutritious snack options, characterized by their naturally high fiber and carbohydrate content while being low in fat (Lee and Hsieh, 2008). The low-fat content is consistent with the composition of the primary ingredients (mango and dragon fruit peel), which are naturally low in fat (Daniel et al., 2014; Maldonado-Celis et al., 2019). The slight increase in fat content in the spiced version may be attributed to trace amounts of fat in cumin and cayenne powder (URMC, 2025a).

The total ash content (dry basis %) was 3.74±0.41% in the spiced version and 3.70±0.38% in the spice-free version. Ash content reflects the total mineral content of the leather and is influenced by the ash content of dragon fruit peel and mango (Biswas et al., 2022; Maldonado-Celis et al., 2019). The small difference indicates minimal contribution from the added spices (URMC, 2025b).

The total carbohydrate content (dry basis %) was 20.58±1.52% with spices and 20.55±1.50% without spices. The similar values confirm that spices had little to no effect on the carbohydrate profile of the leather. The carbohydrate content predominantly originates from mango and honey, as reported in similar fruit and honey-based nectar studies (Lakhanpal and Vaidya, 2015).

The calculated energy value was 98.14±1.93 kcal/100 g with spices and 97.76±1.8 kcal/100 g without spices. These values are lower than typical fruit leathers due to the high fiber and low-fat composition of the product. Similar finding has been reported where high-fiber components lead to lower caloric content (Zahid et al., 2021).

Table 2: Proximate composition of dragon peel-mango leathers

| Parameters | With spices (Mean±SD) | Without spices (Mean±SD) |

| Moisture (%) | 13.76±0.75 | 13.76±0.75 |

| Crude protein (DB %) | 2.74±0.19 | 2.72±0.18 |

| Crude fiber (DB %) | 33.91%±2.67 | 33.91±2.67 |

| Crude fat (DB %) | 0.54±0.03 | 0.52±0.04 |

| Total ash (DB %) | 3.74±0.41 | 3.70±0.38 |

| Total carbohydrate (DB %) | 20.58±1.52 | 20.55±1.53 |

| Energy value (Kcal/100 g) | 98.14±1.93 | 97.76±1.8 |

DB=Dry Basis

Sensory analysis

Sensory analysis

Comparison between the mean values of different sensory attributes of two formulated products is demonstrated in Figure 2. The sensory evaluation results of two fruit leather samples with or without spices (A and B) based on a seven-point hedonic scale are shown in Table 3. Although there was a slight variation in the appearance of the samples, there were no significant differences (p>0.05) between them. This suggests that the appearance of both samples was moderately liked by the panelists. Both samples appeared reddish-brown due to the presence of betacyanin in the dragon fruit peel, which provides red or purple pigmentation (Liaotrakoon, 2013). Additionally, enzymatic browning contributed to the color development (Diop et al., 2022).

The odor of the samples was significantly (p<0.05) affected by the presence of spices. Panelists preferred sample A over sample B due to the spicy and slightly bitter smell of cumin powder (Amin, 2012) and cayenne pepper powder (Yang et al., 2020) that enhance mucus or saliva production, leading to the active dilution of aroma compounds in the oral-nasal cavity.

The odor of the samples was significantly (p<0.05) affected by the presence of spices. Panelists preferred sample A over sample B due to the spicy and slightly bitter smell of cumin powder (Amin, 2012) and cayenne pepper powder (Yang et al., 2020) that enhance mucus or saliva production, leading to the active dilution of aroma compounds in the oral-nasal cavity.

Figure 2: Comparative sensory evaluation of product A (with spices) and product B (without spices) based on appearance, odor, texture, taste, spiciness, chewiness, and overall acceptability.

No significant (p>0.05) differences were evaluated between the texture of the two samples. It is important to consider that the human mouth is more complex and reliable than a penetrometer for evaluating texture, given that the former one only evaluates a single aspect or feature of texture (Huang and Hsieh, 2005; Nollet, 2004). Both samples, formulated with or without spices, have an improved, soft, and flexible texture. Honey has an impact on the improved texture of the leather. Another study reported similar findings (Kaleem et al., 2017) in which the use of honey over sucrose improved the texture of strawberry leather. Moreover, dragon peel and sucrose concentration do not have any significant (p>0.05) effect on the texture of fruit leather (Mardhatilah et al., 2018).

Increasing levels of sucrose lower the extensibility of mango fruit leather, leading to less chewiness. Since our leathers do not contain any sucrose, the chewiness of the leathers is improved and does not have any significant (p>0.05) differences between them.

Increasing levels of sucrose lower the extensibility of mango fruit leather, leading to less chewiness. Since our leathers do not contain any sucrose, the chewiness of the leathers is improved and does not have any significant (p>0.05) differences between them.

Table 3: Comparison of sensory attributes between product A (with spices) and product B (without spices) with mean±Standard Deviation (SD) and statistical significance

| Sensory Attribute | Product*A (Mean±SD) | Product **B (Mean±SD) | p-value |

| Appearance | 5.167±1.020 | 5.100±1.561 | p>0.05 |

| Odor | 5.433±0.626 | 4.933±1.081 | p<0.05 |

| Texture | 5.233±0.935 | 5.333±1.241 | p>0.05 |

| Taste | 5.100±1.094 | 4.867±1.383 | p>0.05 |

| Spiciness | 5.000±0.871 | 4.567±1.591 | p>0.05 |

| Chewiness | 5.000±1.145 | 5.267±1.048 | p>0.05 |

| Overall acceptability | 5.633±0.556 | 5.167±1.020 | p<0.05 |

*A=(with spices), **B=(without spices)

Taste is a very important component in determining the level of consumer acceptance (Ann et al., 2012). The taste score of two samples, A (with spices) and B (without spices), recorded 5.069 and 4.862, respectively. Although there were no significant (p>0.05) differences between the samples, the panelists preferred sample A due to its spiciness. Sweet products are generally favored by consumers, but excessive sweetness can lead to disliked (Jain et al., 2011).

For spiciness, sample A was evaluated as spicier than sample B by the panelists, but no regression (p>0.05) was analyzed. Both samples exhibited a bittersweet, tangy taste, likely derived from dragon peel and mango pulp (Ellong et al., 2015). Similar findings were reported in another study (Putra et al., 2024) where dragon peel mixed with soy whey in a 90:10 ratio to prepare an ice cream, yielded the highest taste score. Regarding overall acceptability, the presence of spices has a significant (p<0.05) impact on the overall acceptability score, with panelists favoring Sample A over B. This aligns with prior research showing that overall acceptability of the product is influenced by taste and aroma (Karmas and Harris, 2012).

Shelf-life

The microbiological status of the developed products ensures consumer safety. Mesophilic anaerobe, coliform, yeast, and mold counts are presented in Table 4. All counts were below the standard limits for safe consumption (Robertson, 2009). This outcome may be attributed to preliminary processes, such as steaming for a specific duration and promptly packing the products into HDPE post-cooling, which significantly reduced microbial load. Both samples tested negative for coliforms, confirming compliance with the standard limits for human consumption (Institute of Medicine and National Research Council, 1985).

The fruit leather was analyzed by trained panelists at one-month intervals for four months. The obtained data on fruit leather are represented in Table 5. The range of the data was 4.5-6.5 for color, flavor, texture, taste, and overall acceptability, while the mean value was higher than five, representing a stable product at the end of the storage time. Our findings align with another study that evaluated different types of fruit leather and their quality parameters during storage (Naz, 2012). These results are consistent with other findings regarding the stability of sensory attributes such as color, flavor, and texture during storage (Purwandari et al., 2018). Table 5 shows that the fruit leather remained a stable product throughout the storage period; however, the mean value for texture was higher (5.85), whereas the mean value for flavor was lower (5.4). The values in the table indicate that the fruit leather was sensorily acceptable with respect to color, flavor, texture, taste, and overall acceptability for up to four months (Vijayanand et al., 2000).

For spiciness, sample A was evaluated as spicier than sample B by the panelists, but no regression (p>0.05) was analyzed. Both samples exhibited a bittersweet, tangy taste, likely derived from dragon peel and mango pulp (Ellong et al., 2015). Similar findings were reported in another study (Putra et al., 2024) where dragon peel mixed with soy whey in a 90:10 ratio to prepare an ice cream, yielded the highest taste score. Regarding overall acceptability, the presence of spices has a significant (p<0.05) impact on the overall acceptability score, with panelists favoring Sample A over B. This aligns with prior research showing that overall acceptability of the product is influenced by taste and aroma (Karmas and Harris, 2012).

Shelf-life

The microbiological status of the developed products ensures consumer safety. Mesophilic anaerobe, coliform, yeast, and mold counts are presented in Table 4. All counts were below the standard limits for safe consumption (Robertson, 2009). This outcome may be attributed to preliminary processes, such as steaming for a specific duration and promptly packing the products into HDPE post-cooling, which significantly reduced microbial load. Both samples tested negative for coliforms, confirming compliance with the standard limits for human consumption (Institute of Medicine and National Research Council, 1985).

The fruit leather was analyzed by trained panelists at one-month intervals for four months. The obtained data on fruit leather are represented in Table 5. The range of the data was 4.5-6.5 for color, flavor, texture, taste, and overall acceptability, while the mean value was higher than five, representing a stable product at the end of the storage time. Our findings align with another study that evaluated different types of fruit leather and their quality parameters during storage (Naz, 2012). These results are consistent with other findings regarding the stability of sensory attributes such as color, flavor, and texture during storage (Purwandari et al., 2018). Table 5 shows that the fruit leather remained a stable product throughout the storage period; however, the mean value for texture was higher (5.85), whereas the mean value for flavor was lower (5.4). The values in the table indicate that the fruit leather was sensorily acceptable with respect to color, flavor, texture, taste, and overall acceptability for up to four months (Vijayanand et al., 2000).

Table 4: Microbiological features of dragon peel mango leather during four months of storage

| Microbes Count | Product-A | Product-B |

| Mesophilic aerobes (CFU/g) | <10 | <10 |

| Mold and yeast (CFU/g) | <100 | <100 |

| Coliform (N/g) | Negative | Negative |

CFU=Colony Forming Unit

Table 5: Quality parameters of dragon peel mango leather assessed at 30 day intervals over 4 months

Table 5: Quality parameters of dragon peel mango leather assessed at 30 day intervals over 4 months

| Month | Color | Flavor | Texture | Taste | Overall |

| 1st month | 6.2 | 5.8 | 6.4 | 6.0 | 6.2 |

| 2nd month | 6.2 | 5.6 | 6.2 | 6.0 | 6.0 |

| 3rd month | 5.4 | 5.2 | 5.6 | 5.6 | 5.6 |

| 4th month | 5.0 | 5.0 | 5.2 | 5.2 | 4.8 |

| Mean±SD | 5.70±0.60 | 5.40±0.37 | 5.85±0.55 | 5.70±0.38 | 5.65±0.62 |

Conclusion

Dragon peel, an underutilized by-product of fruit rich in fiber and its low in fat, offers significant dietary benefits. This study repurposes dragon fruit peel, a by-product typically discarded as waste, into a nutritious, functional snack with notable sensory appeal and health benefits. The physicochemical and nutritional analyses confirmed the product's suitability as a snack, providing significant dietary fiber, and antioxidant content while maintaining low moisture levels to ensure shelf stability. The product is entirely organic, as no synthesized materials were used. Moreover, the microbiological and sensory assessments validated the product's safety and acceptability over a four-month storage period. Notably, the spiced formulation stood out for its enhanced flavor and aroma, achieving higher sensory acceptability among panelists. This study contributes to the growing field of functional food innovation by addressing sustainability goals. However, the small sample size of sensory evaluation study might have constrained customer preference insights, and longer-term storage analyses could provide a more comprehensive understanding of stability under varying environmental conditions. Future research should explore other by-products, optimize formulations, conduct larger sensory evaluations, and improve packaging for improved shelf stability. Additionally, assessing economic feasibility and sustainability will further enhance the market viability of such innovations.

Author Contributions

U.D., M.A.B.H., T.H., A.R., and A.M. designed the study, conducted the experimental work, analyzed the data, and wrote the manuscript; S.M., J.T., S.A., and N.S.F. conducted the experimental work; S.M., and S.B. contributed to data analysis. All authors read and approved the final manuscript.

Acknowledgments

The authors are grateful to the authorities of Universiti Malaysia Terengganu for their support and allowing them to utilize the needed facilities for this research.

Conflicts of Interest

The authors declare that there is no conflict of interest.

Funding

This research received no specific grant from any funding agency in the public, commercial, or non-profit sectors.

Ethical consideration

Not applicable.

References

Amin G. (2012). Cumin. In: Peter K.V. (Editor). Handbook of herbs and spices. Woodhead Publishing, Sawston, Cambridge. pp: 250-259. [DOI: 10.1533/9780857095671.250]

Andrés-Bello A., Barreto-Palacios V., García-Segovia P., Mir-Bel J., Martínez-Monzó J. (2013). Effect of pH on color and texture of food products. Food Engineering Reviews. 5: 158-170. [DOI: 10.1007/s12393-013-9067-2]

Ann K.C., Suseno T.I.P., Utomo, A.R. (2012). Effect of red beet extract and gelatin concentration on physicochemical properties and organoleptic of marshmallow beet. Journal of Food Technology and Nutrition. 11: 28-36. [DOI: 10.33508/jtpg.v11i2.1472]. [Indonesian with English abstract]

Association of Official Analytical Chemists (AOAC). (1931). Official methods of analysis of the Association of Official Analytical Chemists (Volume 3). Association of Official Analytical Chemists. University of Michigan. URL: https://books.google.com/books/ about/Official_Methods_of_Analysis_of_the_Asso.html?id=6O7RAAAAMAAJ. Accessed 24 January 2025.

Azeredo H.M.C., Brito E.S., Moreira G.E.M., Farias V.L., Bruno L.M. (2006). Effect of drying and storage time on the physico‐chemical properties of mango leathers. International Journal of Food Science and Technology. 41: 635-638. [DOI: 10.1111/j.1365-2621.2005.01120.x]

Baloš M.Ž., Jakšić S., Popov N., Mihaljev Ž., Pelić D.L. (2019). Comparative study of water content in honey produced in different years. Archives of Veterinary Medicine. 12: 43-53. [DOI: 10.46784/e-avm.v12i1.42]

BeMiller J.N. (2017). Carbohydrate analysis. In: Nielsen S.S. (Editor). Food analysis. Springer, Cham. pp: 333-360. [DOI: 10.1007/978-3-319-45776-5_19]

Biswas O., Kandasamy P., Das S.K. (2022). Effect of dragon fruit peel powder on quality and acceptability of fish nuggets stored in a solar cooler (5±1° C). Journal of Food Science and Technology. 59: 3647-3658. [DOI: 10.1007/s13197-022-05377-5]

Chavan R.F., Jadhao V.G., Sakhale B.K. (2016). Studies on preparation of mango-sapota mixed fruit bar. South Asian Journal of Food Technology and Environment. 2: 361-365.

Cheok C.Y., Mohd Adzahan N., Abdul Rahman R., Zainal Abedin N.H., Hussain N., Sulaiman R., Chong G.H. (2018). Current trends of tropical fruit waste utilization. Critical Reviews in Food Science and Nutrition. 58: 335-361. [DOI: 10.1080/10408398. 2016.1176009]

Chima Ogbonna A., Izuchukwu Abuajah C., Glory, Ekpe E. (2013). A comparative study of the nutritive factors and sensory acceptance of juices from selected Nigerian fruits. Croatian Journal of Food Technology, Biotechnology and Nutrition. 8: 47-51.

Chumroenvidhayakul S., Thilavech T., Abeywardena M., Adisakwattana S. (2023). Dragon fruit peel waste (Hylocereus undatus) as a potential ingredient for reducing lipid peroxidation, dietary advanced glycation end products, and starch digestibility in cookies. Antioxidants. 12: 1002. [DOI: 10.3390/antiox12051002]

Daniel R.S., Osfar S., Dan Irfan H.D. (2014). Study of nutrient and anthocyanins pigments contents on three kinds of dragon fruit peel meal (hylocereus sp.) as feedstuff. URL: https://fapet.ub.ac.id/wp-content/uploads/ 2014/06/KAJIAN-KANDUNGAN- ZAT-MAKANAN- DAN-PIGMEN-ANTOSIANIN-TIGA- JENIS-KULIT-BUAH- NAGA-Hylocereus-Sp.-SEBAGAI- BAHAN-PAKAN-TERNAK.pdf. [Indonesian with English abstract]

Deepika D., Panja P. (2017). Enrichment on quality of aonla (Emblica officinalis G.) fruit bars by blending. Journal of Applied and Natural Science. 9: 162-166. [DOI:10.31018/jans.v9i1.1165]

Dharma A.S.B, Widodo F., Lo D. (2024). Physicochemical and sensory analysis of fruit leather made from orange peel and dragon fruit peel with isomalto-oligosaccharides as sucrose substitute. Food Science and Technology. 12: 62-70. [DOI: 10.13189/ fst.2024.120105]

Diamante L.M., Bai X., Busch J. (2014). Fruit leathers: method of preparation and effect of different conditions on qualities. International Journal of Food Science. 2014: 139890. [DOI: 10.1155/2014/139890]

Diop A., Méot J.-M., Léchaudel M., Chiroleu F., Ndiaye N.D., Mertz C., Cissé M., Chillet M. (2022). Impact of special drying schemes on color stability of mangoes with different maturity degrees. Foods. 11: 656. [DOI: 10.3390/foods11050656]

Downes F.P, Ito K. (2001). Compendium of methods for the microbiology examination of foods. 5th edition. American Public Health Association, Washington, DC. [DOI: 10.2105/MBEF.0222]

Ellong E.N., Adenet S., Rochefort K. (2015). Physicochemical, nutritional, organoleptic characteristics and food applications of four mango (Mangifera indica) varieties. Food and Nutrition Sciences. 6: 242-253. [DOI: 10.4236/fns.2015.62025]

Gondim J.A.M., Moura M.D.F.V., Dantas A.S., Medeiros R.L.S., Santos K.M. (2005). Centesimal composition and minerals in peels of fruits. Food Science and Technology. 25: 825-827. [DOI: 10.1590/S0101-20612005000400032]

Haytowitz D.B., Ahuja J.K.C., Wu X., Somanchi M., Nickle M., Nguyen Q.A., Roseland J.M., Williams J.R., Patterson K.Y., Li Y., Pehrsson P.R. (2019). USDA National nutrient database for standard reference, legacy release. Nutrient Data Laboratory, Beltsville Human Nutrition Research Center, ARS, USDA. [DOI: 10.15482/USDA.ADC/1529216]

Huang X., Hsieh F.H. (2005). Physical properties, sensory attributes, and consumer preference of pear fruit leather. Journal of Food Science. 70: E177-E186. [DOI: 10.1111/j.1365-2621.2005. tb07133.x]

Institute of Medicine and National Research Council (1985). An evaluation of the role of microbiological criteria for foods and food ingredients. National Academies Press, Washington, DC. [DOI: 10.17226/372]

Jain P.K., Jain P., Nema P.K. (2011). Quality of guava and papaya fruit pulp as influenced by blending ratio and storage period. American Journal of Technology 6: 507-512. [DOI: 10.3923/ajft.2011. 507.512]

Jalgaonkar K., Mahawar M.K., Bibwe B., Kannaujia P. (2022). Postharvest profile, processing and waste utilization of dragon fruit (Hylocereus spp.): a review. Food Reviews International. 38: 733-759. [DOI: 10.1080/87559129.2020.1742152]

Jamilah B., Shu C.E., Kharidah M., Dzulkily M.A., Noranizan A. (2011). Physico-chemical characteristics of red pitaya (Hylocereus polyrhizus) peel. International Food Research Journal. 18:279.

Javaria S., Marwat A., Nadeem M., Zerlasht M., Kareem A., Rubab I., Munir M. (2021). Development and physico-chemical characterization of apple-peach fruit leather. Pakistan Journal of Agricultural Research. 34: 254-493. [DOI: 10.17582/journal.pjar/2021/34.2.318.324]

Jethva K.R., Rathod S.R., Pargi A.S. (2023). Optimization of process variables for development of dragon fruit leather by using fruit peel as by-product utilization. The Pharma Innovation Journal.12: 1154-1159.

Kaleem M., Qazi I.M., Khan A., Khan M.A., Hussain I., Ayub M., Shinwari A.S., Shah F.N., Rehman A.U. (2017). Effect of different concentrations of sucrose and honey on the physiochemical and sensory properties of strawberry leather. Pakistan Journal of Scientific and Industrial Research, Series B: Biological Sciences. 60: 1-62.

Karel M., Anglea S., Buera P., Karmas R., Levi G., Roos Y. (1994). Stability-related transitions of amorphous foods. Thermochimica Acta. 246: 249-269. [DOI: 10.1016/0040-6031(94)80094-4]