Volume 12, Issue 3 (September 2025)

J. Food Qual. Hazards Control 2025, 12(3): 201-209 |

Back to browse issues page

Ethics code: Not applicable.

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Hasan R, Islam M, Jobair A, Afrin S, Islam N, Begum R. A Comparative Quality Evaluation of Whey Powder Using Spray and Freeze Drying Methods. J. Food Qual. Hazards Control 2025; 12 (3) :201-209

URL: http://jfqhc.ssu.ac.ir/article-1-1308-en.html

URL: http://jfqhc.ssu.ac.ir/article-1-1308-en.html

Department of Food Technology and Nutritional Science, Mawlana Bhashani Science and Technology University, Santosh, Tangail-1902, Bangladesh , rokeya.ftns@mbstu.ac.bd

Full-Text [PDF 513 kb]

(969 Downloads)

| Abstract (HTML) (574 Views)

A Comparative Quality Evaluation of Whey Powder Using Spray and Freeze Drying Methods

R. Hasan, M. Islam, A.B. Jobair, S. Afrin, N. Islam, R. Begum **

Department of Food Technology and Nutritional Science, Mawlana Bhashani Science and Technology University, Santosh, Tangail-1902, Bangladesh

HIGHLIGHTS

To cite: Hasan R., Islam M., Jobair A.B., Afrin S., Islam N., Begum R. (2025). A comparative quality evaluation of whey powder using spray and freeze drying methods. Journal of Food Quality and Hazards Control. 12: 201-209.

±  Standard Deviation (SD) of three replicate. Different superscript letters within the same row indicate statistically significant differences at p<0.05.

Standard Deviation (SD) of three replicate. Different superscript letters within the same row indicate statistically significant differences at p<0.05.

-Moisture content

Spray-dried whey powder exhibited a significantly lower moisture content (p<0.05) than freeze-dried whey powder. Lower moisture content in Spray dried powder may attribute to a crispy texture. Both drying techniques yielded whey powder with a moisture content less than 5%, complying with the Codex Alimentarius guidelines (FAO and WHO, 1999). Previous studies have shown that spray-dried and freeze-dried whole camel milk powders retain moisture levels of 2.43% and 2.81%, respectively (Deshwal et al., 2020). Tastemirova et al. (2020) reported that camel milk powder obtained through spray drying contained between 1.10% and 1.94% moisture, while freeze-dried samples retained moisture levels ranging from 2.44% to 3.00%. Similar findings were reported by Franceschinis et al. (2014), where spray dried powder retained lower moisture content than freeze dried powder. These findings align with the results of the present study. The moisture content in this study was at an optimal level to maintain microbiological safety, enhance storage stability, and reduce biochemical degradation of the whey powder (FAO and WHO, 1999). Therefore, this study demonstrated that the spray drying method produces whey powder with lower moisture content than freeze drying.

-Protein content.

No statistically significant difference (p>0.05) was observed in protein content between whey powder samples produced by spray drying and freeze drying. However, the present study revealed significantly higher whey protein retention in both spray dried and freeze dried powders relative to previous studies. The observed differences likely result from variations in processing techniques, geographical factors, and the milk's maturation phase. Previous studies report protein contents of 14.20±0.18% in spray dried goat whey powder (Pinheiro et al., 2024) and 10-14.33% in freeze dried Tulum whey powder (Güzeler et al., 2017). Consistent with findings for whole camel milk powder (Deshwal et al., 2020), current study revealed no significant protein content variation between drying techniques.

-Titratable acidity

Spray-dried whey powder exhibited significantly greater titratable acidity (p<0.05) compared to freeze-dried whey powder. This difference may be attributed to variations in processing parameters including temperature, chamber volume, production capacity, and heating duration in the drying systems (Chegini et al., 2014). Kumar et al. (2016) reported 0.07-0.25% acidity in rennet-type whey; moreover, significantly higher values (1.56±0.59%) were observed in freeze-dried Beyaz whey powder (Güzeler et al., 2017). According to Codex Alimentarius Commission (1995), whey powders must not exceed 0.16% titratable acidity (as lactic acid). The results of this study are in agreement with the Codex standards. The concentration of maltodextrin used in whey preparation contributed to a reduction in acidity. The current study found that the freeze dried whey powder exhibited lower titratable acidity.

Physical properties of whey powder

-Color

The color of whey powder is a crucial factor as it affects the visual appeal of the final product. Table 2 demonstrated the color (L*, a*, and b*) parameters of spray drying and freeze drying whey powder. There were significant variations (p<0.05) in the Hunter color values among powders. The L* (lightness) value was significantly greater in spray-dried whey powder compared to freeze-dried powder. This is likely due to the rapid evaporation and moderate heat in spray drying, which allows maltodextrin to form smooth, reflective surfaces. In contrast, freeze drying produces porous particles where maltodextrin has less impact on surface brightness. According to previous studies, the L* values of whey powder ranged from 90.9 to 91.63 in various regions (Sithole et al., 2005), and from 84.97 to 85.35 in freeze-dried whey powder (Culver and Wrolstad, 2008). These values are comparable to those observed in the present study. The current study also found that the freeze-dried powder exhibited a more greenish hue compared to the spray-dried powder. This is supported by previous research reporting a* values for whey powder ranging from -0.42 to -0.59 across various regions (Sithole et al., 2005), indicating a slight green hue. Another study reported a range of a* value from -1.50 to +1.75 under different environmental conditions in whey powder (Sithole et al., 2006), and -1.20 in milk powder (Deshwal et al., 2020). These findings are consistent to the results of current study. Furthermore, the current study revealed that the freeze dried powder appeared more yellowish than the spray dried powder. Previous studies have reported that the b* values in whey powder ranged from 8.6 to 24.5, while in milk powder, they ranged from 8.30 to 11.92, depending on various factors (Sithole et al., 2006).

The foaming capacity was measured immediately after homogenization (0 min), while foam stability was assessed at 30 and 60 min intervals.

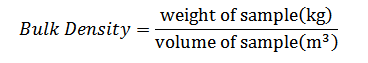

-Bulk density

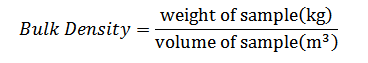

According to Fadila et al. (2025), bulk density was measured by placing approximately 2 g of whey powder into a 10 ml graduated cylinder and tapping it repeatedly (20–30 times) until the volume stabilized. The final settled volume was recorded, and bulk density was calculated using the following formula:

-Tapped density

The tapped density of the whey powder was measured following the standardized procedure outlined by Fadila et al. (2025). About 2 g of the powder sample was accurately placed into a clean, dry 10 ml graduated cylinder. The cylinder was then subjected to 100 controlled taps against a firm laboratory bench pad until the powder volume reached equilibrium (no further volume reduction). The final compacted volume was recorded after tapping, and the tapped density was calculated using the following formula:

-Carr’s index

Carr's index, an indicator of powder flowability and compressibility, was determined following the method of Fadila et al. (2025) using the equation:

-Hausner ratio

Hausner ratio, a parameter characterizing powder flowability, was calculated according to Fadila et al. (2025) using the following equation:

Statistical analysis

One-way Analysis of Variance (ANOVA) was conducted using the Statistical Package for the Social Sciences (SPSS) version 22.0 (SPSS Inc., Chicago, IL), followed by Duncan’s Multiple Range Test (DMRT) to determine significant differences at the 5% significance level (p< 0.05) with a 95% confidence interval.

Results and discussion

Chemical composition of whey powder

Table 1 illustrates notable differences in the chemical composition of whey powder produced by the two drying techniques.

Table 1: Chemical composition of whey powder (n=6)

Table 2: Physical properties of whey powder (n=6)

Table 3: Functional properties of whey powder (n=6)

Table 4: Criteria for Carr’s index and Hausner ratio

Conflicts of interest

The authors declare that there is no conflict of interest.

Funding

This research received no specific grant to conduct this research.

Ethical consideration

There were no human subject experiments in the study.

References

Full-Text: (25 Views)

A Comparative Quality Evaluation of Whey Powder Using Spray and Freeze Drying Methods

R. Hasan, M. Islam, A.B. Jobair, S. Afrin, N. Islam, R. Begum **

Department of Food Technology and Nutritional Science, Mawlana Bhashani Science and Technology University, Santosh, Tangail-1902, Bangladesh

- Spray drying resulted in lower moisture and higher acidity, with similar protein content.

- Spray-dried powder exhibited superior color and wettability comparing to freeze-dried powder.

- Spray drying offered better flowability and economic viability for large-scale production.

| Article type Original article |

ABSTRACT Background: Whey powder production from whey, a dairy by-product, remains a significant challenge. This study aimed to evaluate how spray drying and freeze drying methods influence the quality of whey powder by comparing their physical, chemical, and functional characteristics. Methods: Six whey samples were collected from a local manufacturer in September 2024 with three processed by spray drying and three by freeze drying. Spray drying was performed at an inlet temperature of 160 °C and freeze drying at -41 to -65 °C under vacuum pressure (0.05 mbar), both with 5% maltodextrin added. The powders were analyzed for physical (color, solubility, hygroscopicity, and wettability), chemical (moisture content, protein content, and titratable acidity), and functional (bulk density, tapped density, Carr’s index, Hausner ratio, foaming capacity, and foaming stability) properties following AOAC and standard methods. Statistical analysis employed one-way ANOVA and Duncan's Multiple Range Test using SPSS (version 22.0, SPSS Inc., Chicago, IL) at a 5% significance level (p<0.05). Results: Spray dried powder had significantly lower moisture (3.26%) and higher titratable acidity than freeze dried powder (p<0.05); nevertheless, there was no apparent difference in the protein content (20-21.01%). Spray dried powder appeared lighter and less greenish in color, whereas freeze dried powder exhibited more yellowish and greenish tones. Solubility (98.76-98.87%) and hygroscopicity (49.06-49.26%) were not significantly different. However, spray dried powder showed lower wettability (154 s). No significant differences were observed in bulk and tapped densities. Flowability was poor in spray dried powder and very poor in freeze dried powder. Freeze dried powder showed significantly higher foaming capacity and stability (p<0.05). Conclusion: Both drying techniques are suitable for large-scale production, depending on their specific uses within the food and pharmaceutical sectors. However, considering factors such as stability, flowability, and economic viability, spray dried powder demonstrated higher efficacy than freeze dried powder. © 2025, Shahid Sadoughi University of Medical Sciences. This is an open access article under the Creative Commons Attribution 4.0 International License. |

|

| Keywords Whey Proteins Freeze Drying Spray Drying Dairy Products |

||

| Article history Received: 28 Dec 2024 Revised: 26 Mar 2025 Accepted: 2 Sep 2025 |

||

| Abbreviations FTIR=Fourier Transform Infrared Spectroscopy IEP=Isoelectric Point SDS-PAGE=Sodium Dodecyl Sulfate Polyacrylamide Gel Electrophoresis |

To cite: Hasan R., Islam M., Jobair A.B., Afrin S., Islam N., Begum R. (2025). A comparative quality evaluation of whey powder using spray and freeze drying methods. Journal of Food Quality and Hazards Control. 12: 201-209.

Introduction

Whey is a pale yellow-green, easily perishable liquid that results as a by-product during the production of dairy items such as cheese, channa, paneer, chakka, and casein (Deshmukh et al., 2024; Deshwal et al., 2020). Globally, a substantial portion of milk up to 80-90% of its volume is discarded as whey during cheese production (Buchanan et al., 2023). Although often regarded as a waste byproduct, whey contains a wealth of essential nutrients, including lactose, lipids, B-complex vitamins, and minerals such as calcium (Ca), sodium (Na), potassium (K), magnesium (Mg), and phosphorus (P). It is also an excellent source of high-quality proteins, including β-lactoglobulin, α-lactalbumin, lactoferrin, and immunoglobulins (Tsermoula et al., 2021). Whey proteins are well-known for their health-promoting effects, including enhancement of muscle growth, immune modulation, and potential roles in reducing risks of cardiovascular diseases and osteoporosis due to their antioxidant, antihypertensive, and antithrombotic properties (Olvera-Rosales et al., 2022). Whey is widely used in the production of various value-added products such as whey protein concentrates, condensed whey, whey protein isolates, modified dry whey, and whey powder. Among these, whey powder finds broad application in the formulation of beverages, bakery products, infant foods, and dietary supplements (Goff et al., 2022). However, a significant volume of whey remains underutilized and is often discarded, contributing to environmental pollution, particularly when released untreated into water bodies (Sirmacekic et al., 2022). Hence, efficient recovery and valorization of whey through sustainable processing methods is critical for both environmental and economic perspectives. Drying is a common preservation technique that extends shelf-life and stabilizes perishable materials by reducing moisture content under controlled thermal conditions (Begum et al., 2017). To turn liquid whey into powder, two efficient methods are spray drying and freeze drying. Spray drying is extensively employed because of its cost-effectiveness, ease of operation, rapid processing, and efficient energy use (Gaspar et al., 2014). In contrast, freeze drying is ideal for heat-sensitive compounds, preserving the nutritional and sensory integrity of the product through sublimation under low temperatures (Oliveira et al., 2016). Several comparative studies have evaluated the influence of spray drying and freeze drying on the quality of various food powders. According to Kucharska-Guzik et al. (2025), smaller and more consistent particles are produced by spray drying, and these are usually associated with improved dispersion and increased stability in formulations. In addition, spray drying offers advantages in terms of process speed, along with acceptable retention of physical and functional properties (Pui and Saleena, 2022; Rannou et al., 2015). Freeze drying produces larger particles with a wider size distribution, which can be beneficial for applications that demand lower bulk density or improved flowability (Kucharska-Guzik et al., 2025). Freeze-drying also reported to retain higher levels of phenolic compounds, flavonoids, antioxidant activity, and color attributes during long-term storage (Babaei et al., 2025; Coşkun et al., 2024). Even while fruit extracts, dairy powders, and other plant-based formulations have been the focus of most comparative investigations, there is still a large gap in the literature about the precise application of these drying techniques to whey. Most existing research has concentrated on whey composition, protein isolation, and utilization (Vasiljevic and Duke, 2015) rather than the impact of processing techniques on final powder quality. Consequently, there is a lack of comprehensive evidence directly comparing the effectiveness of spray drying and freeze drying in maintaining the physicochemical and functional properties of whey powder. Thus, the purpose of this study is to assess how spray drying and freeze drying affect the physicochemical and functional characteristics of whey powder, providing important information on their potential for the sustainable use of dairy by-products.

Materials and methods

Collection and preparation of raw materials

The whey sample (voucher no.: MV-7140; Bangladesh) was collected on 20th September, 2024 and sourced from “Milk Vita of Tangail,” a local cheese production facility. The whey originated from a mixed herd of Friesian crossbred and Sahiwal crossbred cows. The freshly extracted whey underwent a filtration process to remove suspended solids, followed by High Temperature Short Time (HTST) pasteurization at 72±1 °C for 15 s to eliminate pathogenic microorganisms. Using a digital refractometer (Atago Co., Japan), the content of Total Soluble Solids (TSS) was determined to be 8.0%, and the pH was determined as 4.28 using a calibrated pH meter (Mettler Toledo, Switzerland). To improve drying efficiency and reduce stickiness in the final powder, 5% (w/w) maltodextrin (ChemSyte, Bangladesh) was added to the whey, followed by thorough mixing. Maltodextrin was added to improve powder quality, enhance flowability, prevent stickiness, and protect heat-sensitive nutrients (Ozcelik and Kulozik, 2023). The mixture was subsequently filtered three times through muslin cloth to eliminate any remaining particulates prior to the drying process.

Spray drying process

A laboratory-scale spray dryer (Yamato, Japan) was used with the following parameters: the inlet air temperature was set at 160 °C, the exit temperature was kept between 80 and 90 °C, the aspirator rate was set at 100%, and the atomizing air flow rate was set at 0.1. The pump rate was set to 2.5 and the blower rate at 7.5. The resultant powders were quickly gathered after drying, placed in zip-lock bags, and kept at room temperature in a desiccator with a relative humidity of 0-3% until additional examination.

Freeze drying process

Before freeze drying, the previously prepared whey mixture was placed in glass bottles and cooled to -18 °C for 24 h in a chiller (Liebherr Mediline, Germany). A lab pilot freeze dryer (ilShin Biobase, South Korea) was used for this process. The whey mixture was placed in the glass bottles of the dryer, and it was operated at a range -41 to -65 °C and at 0.05 mbar chamber pressure. The drying process lasted 48 h. The resulting cake was ground using a grinder (Kenwood, Spain) for 1 min and then passed through a 0.05 mm sieve to obtain the desired powder. The powders were immediately transferred into zip-lock bags and stored in a desiccator maintained at a relative humidity of 0-3%.

Composition analysis of whey powder

-Moisture content

The moisture content of the samples was determined according to the standard procedure outlined by AOAC (2005). Approximately 3 g of each sample were accurately weighed using a digital balance (Tech Nation India, India) and transferred into a pre-dried and pre-weighed crucible. The crucible containing the sample was then placed in a hot air oven (SH Scientific, South Korea) maintained at 105 °C. The drying process was carried out with periodic removal of the crucible every 30 min for cooling in a desiccator, followed by weighing. This cycle of drying, cooling, and weighing was repeated until a constant weight was achieved, indicating complete moisture removal. The moisture content was calculated based on the total weight loss of the sample during the drying process.

-Protein content

The protein content of the plant powder was determined following the standard procedures described by Begum et al. (2017) and Fadila et al. (2025). The process began with the digestion of the sample in a Kjeldahl flask using a 5 g digestion mixture composed of potassium sulfate (K₂SO₄; 7778-80-5, Merck, Germany) and copper (II) sulfate (CuSO₄; 7758-98-7, Merck, Germany) in a 98:2 ratio, along with 25 ml of concentrated sulfuric acid (H₂SO₄; 7664-93-9, Merck, Germany). The digestion continued until the solution became clear. After cooling, the digest was diluted with 100 ml of distilled water. For the distillation phase, 75 ml of 40% sodium hydroxide (NaOH; 1310-73-2, Merck, Germany) was added to liberate ammonia. The released ammonia was then trapped in 25 ml of 0.1 N sulfuric acid (H₂SO₄). The resulting distillate was titrated against 0.1 N sodium hydroxide (NaOH), using methyl red as an indicator. A reagent blank was also included in the analysis to ensure accuracy. Based on the titration results, the nitrogen content was calculated, and protein content was derived accordingly.

-Titratable acidity

The titratable acidity of the whey powder was assessed according to the method described by Chegini et al. (2014). In this procedure, 6 g of whey powder was dissolved in 100 ml of deionized water with gentle stirring, then allowed to stand undisturbed for 1 h. Following this, a 20 ml portion of the prepared solution was transferred to a 100 ml flask, to which 0.5 ml of phenolphthalein indicator was added. The mixture was then titrated with 0.1 N sodium hydroxide (NaOH) until a faint pink color developed and remained stable for approximately 30 seconds. Titratable acidity was determined from the consumed NaOH volume, its normality, and the volume of the test solution.

Physical properties analysis of whey

-Powder color

The color characteristics of the whey powder were measured using a colorimeter (Minolta, Japan) following the standard protocol outlined by Fadila et al. (2025). The instrument quantifies the three fundamental chromatic parameters (red, green, and blue) that constitute visible light perception in human vision. The colorimeter outputs L*, a*, and b* values based on the CIE Lab* color space. Here, L* (ranging from 0 to 100) indicates lightness, with 0 representing black and 100 representing white. The a* value reflects the green–red spectrum, where negative values indicate green and positive values indicate red. Similarly, the b* value represents the blue–yellow spectrum, with negative values corresponding to blue and positive values indicating yellow. The range for both a* and b* is -127 to +127.

-Solubility of whey powder

Solubility was assessed following the procedure outlined by Santhalakshmy et al. (2015). About one g of the sample was precisely weighed and dissolved in 100 ml of distilled water. The mixture was then transferred into centrifuge tubes and centrifuged at 3,000 rpm for 5 min, followed by a sedimentation period of 30 min. Subsequently, a 25 ml portion of the supernatant was carefully drawn and placed into a pre-weighed petri dish, which was then dried in a hot air oven at 105 °C for 5 h. Solubility percentage was calculated based on the weight difference.

-Hygroscopicity of powder

The hygroscopicity of the whey powder was assessed using the gravimetric method described by Santhalakshmy et al. (2015). Approximately one g of the sample was placed in a pre-weighed crucible, which was then kept in a desiccator maintained at 25 °C with a saturated sodium chloride (NaCl) solution to create a controlled relative humidity environment. After a 7-day equilibration period, the crucibles were reweighed, and hygroscopicity was expressed as the amount of water absorbed, calculated in grams per 100 g of dry solids.

-Wettability of whey powder

The wettability of the whey powder was measured following the standardized procedure outlined by Santhalakshmy et al. (2015). Approximately 6 g of whey powder was accurately weighed on a digital electronic balance, and 100 ml of deionized water, kept at a controlled temperature of 20 ± 0.2 °C, was carefully added to a beaker. The pre-weighed whey powder was then introduced onto the water surface, and a stopwatch was immediately started. The timer was stopped upon complete wetting of all powder particles, indicated by the absence of any visible dry aggregates. Wettability was calculated using following equation:

Wettability=Time (s) elapsed from powder addition to complete wetting

Estimation of functional properties of whey powder

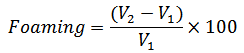

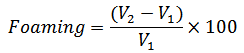

-Foaming properties

The foaming properties of the whey powder were assessed following the method described by Fadila et al. (2025). A 1% (w/v) protein solution was made by dissolving the protein in distilled water, and its pH was adjusted to 7.0 with 1.0 N NaOH. Subsequently, 100 ml (V1) of the whey solution was homogenized at maximum speed for 5 min. The homogenized solution was promptly poured into a 250 ml graduated cylinder, and the foam volume (V₂) was recorded at 0, 30, and 60 min. Foaming was then calculated using the following equation:

Materials and methods

Collection and preparation of raw materials

The whey sample (voucher no.: MV-7140; Bangladesh) was collected on 20th September, 2024 and sourced from “Milk Vita of Tangail,” a local cheese production facility. The whey originated from a mixed herd of Friesian crossbred and Sahiwal crossbred cows. The freshly extracted whey underwent a filtration process to remove suspended solids, followed by High Temperature Short Time (HTST) pasteurization at 72±1 °C for 15 s to eliminate pathogenic microorganisms. Using a digital refractometer (Atago Co., Japan), the content of Total Soluble Solids (TSS) was determined to be 8.0%, and the pH was determined as 4.28 using a calibrated pH meter (Mettler Toledo, Switzerland). To improve drying efficiency and reduce stickiness in the final powder, 5% (w/w) maltodextrin (ChemSyte, Bangladesh) was added to the whey, followed by thorough mixing. Maltodextrin was added to improve powder quality, enhance flowability, prevent stickiness, and protect heat-sensitive nutrients (Ozcelik and Kulozik, 2023). The mixture was subsequently filtered three times through muslin cloth to eliminate any remaining particulates prior to the drying process.

Spray drying process

A laboratory-scale spray dryer (Yamato, Japan) was used with the following parameters: the inlet air temperature was set at 160 °C, the exit temperature was kept between 80 and 90 °C, the aspirator rate was set at 100%, and the atomizing air flow rate was set at 0.1. The pump rate was set to 2.5 and the blower rate at 7.5. The resultant powders were quickly gathered after drying, placed in zip-lock bags, and kept at room temperature in a desiccator with a relative humidity of 0-3% until additional examination.

Freeze drying process

Before freeze drying, the previously prepared whey mixture was placed in glass bottles and cooled to -18 °C for 24 h in a chiller (Liebherr Mediline, Germany). A lab pilot freeze dryer (ilShin Biobase, South Korea) was used for this process. The whey mixture was placed in the glass bottles of the dryer, and it was operated at a range -41 to -65 °C and at 0.05 mbar chamber pressure. The drying process lasted 48 h. The resulting cake was ground using a grinder (Kenwood, Spain) for 1 min and then passed through a 0.05 mm sieve to obtain the desired powder. The powders were immediately transferred into zip-lock bags and stored in a desiccator maintained at a relative humidity of 0-3%.

Composition analysis of whey powder

-Moisture content

The moisture content of the samples was determined according to the standard procedure outlined by AOAC (2005). Approximately 3 g of each sample were accurately weighed using a digital balance (Tech Nation India, India) and transferred into a pre-dried and pre-weighed crucible. The crucible containing the sample was then placed in a hot air oven (SH Scientific, South Korea) maintained at 105 °C. The drying process was carried out with periodic removal of the crucible every 30 min for cooling in a desiccator, followed by weighing. This cycle of drying, cooling, and weighing was repeated until a constant weight was achieved, indicating complete moisture removal. The moisture content was calculated based on the total weight loss of the sample during the drying process.

-Protein content

The protein content of the plant powder was determined following the standard procedures described by Begum et al. (2017) and Fadila et al. (2025). The process began with the digestion of the sample in a Kjeldahl flask using a 5 g digestion mixture composed of potassium sulfate (K₂SO₄; 7778-80-5, Merck, Germany) and copper (II) sulfate (CuSO₄; 7758-98-7, Merck, Germany) in a 98:2 ratio, along with 25 ml of concentrated sulfuric acid (H₂SO₄; 7664-93-9, Merck, Germany). The digestion continued until the solution became clear. After cooling, the digest was diluted with 100 ml of distilled water. For the distillation phase, 75 ml of 40% sodium hydroxide (NaOH; 1310-73-2, Merck, Germany) was added to liberate ammonia. The released ammonia was then trapped in 25 ml of 0.1 N sulfuric acid (H₂SO₄). The resulting distillate was titrated against 0.1 N sodium hydroxide (NaOH), using methyl red as an indicator. A reagent blank was also included in the analysis to ensure accuracy. Based on the titration results, the nitrogen content was calculated, and protein content was derived accordingly.

-Titratable acidity

The titratable acidity of the whey powder was assessed according to the method described by Chegini et al. (2014). In this procedure, 6 g of whey powder was dissolved in 100 ml of deionized water with gentle stirring, then allowed to stand undisturbed for 1 h. Following this, a 20 ml portion of the prepared solution was transferred to a 100 ml flask, to which 0.5 ml of phenolphthalein indicator was added. The mixture was then titrated with 0.1 N sodium hydroxide (NaOH) until a faint pink color developed and remained stable for approximately 30 seconds. Titratable acidity was determined from the consumed NaOH volume, its normality, and the volume of the test solution.

Physical properties analysis of whey

-Powder color

The color characteristics of the whey powder were measured using a colorimeter (Minolta, Japan) following the standard protocol outlined by Fadila et al. (2025). The instrument quantifies the three fundamental chromatic parameters (red, green, and blue) that constitute visible light perception in human vision. The colorimeter outputs L*, a*, and b* values based on the CIE Lab* color space. Here, L* (ranging from 0 to 100) indicates lightness, with 0 representing black and 100 representing white. The a* value reflects the green–red spectrum, where negative values indicate green and positive values indicate red. Similarly, the b* value represents the blue–yellow spectrum, with negative values corresponding to blue and positive values indicating yellow. The range for both a* and b* is -127 to +127.

-Solubility of whey powder

Solubility was assessed following the procedure outlined by Santhalakshmy et al. (2015). About one g of the sample was precisely weighed and dissolved in 100 ml of distilled water. The mixture was then transferred into centrifuge tubes and centrifuged at 3,000 rpm for 5 min, followed by a sedimentation period of 30 min. Subsequently, a 25 ml portion of the supernatant was carefully drawn and placed into a pre-weighed petri dish, which was then dried in a hot air oven at 105 °C for 5 h. Solubility percentage was calculated based on the weight difference.

-Hygroscopicity of powder

The hygroscopicity of the whey powder was assessed using the gravimetric method described by Santhalakshmy et al. (2015). Approximately one g of the sample was placed in a pre-weighed crucible, which was then kept in a desiccator maintained at 25 °C with a saturated sodium chloride (NaCl) solution to create a controlled relative humidity environment. After a 7-day equilibration period, the crucibles were reweighed, and hygroscopicity was expressed as the amount of water absorbed, calculated in grams per 100 g of dry solids.

-Wettability of whey powder

The wettability of the whey powder was measured following the standardized procedure outlined by Santhalakshmy et al. (2015). Approximately 6 g of whey powder was accurately weighed on a digital electronic balance, and 100 ml of deionized water, kept at a controlled temperature of 20 ± 0.2 °C, was carefully added to a beaker. The pre-weighed whey powder was then introduced onto the water surface, and a stopwatch was immediately started. The timer was stopped upon complete wetting of all powder particles, indicated by the absence of any visible dry aggregates. Wettability was calculated using following equation:

Wettability=Time (s) elapsed from powder addition to complete wetting

Estimation of functional properties of whey powder

-Foaming properties

The foaming properties of the whey powder were assessed following the method described by Fadila et al. (2025). A 1% (w/v) protein solution was made by dissolving the protein in distilled water, and its pH was adjusted to 7.0 with 1.0 N NaOH. Subsequently, 100 ml (V1) of the whey solution was homogenized at maximum speed for 5 min. The homogenized solution was promptly poured into a 250 ml graduated cylinder, and the foam volume (V₂) was recorded at 0, 30, and 60 min. Foaming was then calculated using the following equation:

| Parameters | Spray dried powder |

Freeze dried powder |

| Moisture content (%) | 3.26±0.433 a | 3.93±0.356 b |

| Protein content (%) | 20±2.07 a | 21.01±1.84 a |

| Titratable acidity (%) | 0.02±0.06 b | 0.01±0.004 a |

Values are mean

Standard Deviation (SD) of three replicate. Different superscript letters within the same row indicate statistically significant differences at p<0.05.

Standard Deviation (SD) of three replicate. Different superscript letters within the same row indicate statistically significant differences at p<0.05.-Moisture content

Spray-dried whey powder exhibited a significantly lower moisture content (p<0.05) than freeze-dried whey powder. Lower moisture content in Spray dried powder may attribute to a crispy texture. Both drying techniques yielded whey powder with a moisture content less than 5%, complying with the Codex Alimentarius guidelines (FAO and WHO, 1999). Previous studies have shown that spray-dried and freeze-dried whole camel milk powders retain moisture levels of 2.43% and 2.81%, respectively (Deshwal et al., 2020). Tastemirova et al. (2020) reported that camel milk powder obtained through spray drying contained between 1.10% and 1.94% moisture, while freeze-dried samples retained moisture levels ranging from 2.44% to 3.00%. Similar findings were reported by Franceschinis et al. (2014), where spray dried powder retained lower moisture content than freeze dried powder. These findings align with the results of the present study. The moisture content in this study was at an optimal level to maintain microbiological safety, enhance storage stability, and reduce biochemical degradation of the whey powder (FAO and WHO, 1999). Therefore, this study demonstrated that the spray drying method produces whey powder with lower moisture content than freeze drying.

-Protein content.

No statistically significant difference (p>0.05) was observed in protein content between whey powder samples produced by spray drying and freeze drying. However, the present study revealed significantly higher whey protein retention in both spray dried and freeze dried powders relative to previous studies. The observed differences likely result from variations in processing techniques, geographical factors, and the milk's maturation phase. Previous studies report protein contents of 14.20±0.18% in spray dried goat whey powder (Pinheiro et al., 2024) and 10-14.33% in freeze dried Tulum whey powder (Güzeler et al., 2017). Consistent with findings for whole camel milk powder (Deshwal et al., 2020), current study revealed no significant protein content variation between drying techniques.

-Titratable acidity

Spray-dried whey powder exhibited significantly greater titratable acidity (p<0.05) compared to freeze-dried whey powder. This difference may be attributed to variations in processing parameters including temperature, chamber volume, production capacity, and heating duration in the drying systems (Chegini et al., 2014). Kumar et al. (2016) reported 0.07-0.25% acidity in rennet-type whey; moreover, significantly higher values (1.56±0.59%) were observed in freeze-dried Beyaz whey powder (Güzeler et al., 2017). According to Codex Alimentarius Commission (1995), whey powders must not exceed 0.16% titratable acidity (as lactic acid). The results of this study are in agreement with the Codex standards. The concentration of maltodextrin used in whey preparation contributed to a reduction in acidity. The current study found that the freeze dried whey powder exhibited lower titratable acidity.

Physical properties of whey powder

-Color

The color of whey powder is a crucial factor as it affects the visual appeal of the final product. Table 2 demonstrated the color (L*, a*, and b*) parameters of spray drying and freeze drying whey powder. There were significant variations (p<0.05) in the Hunter color values among powders. The L* (lightness) value was significantly greater in spray-dried whey powder compared to freeze-dried powder. This is likely due to the rapid evaporation and moderate heat in spray drying, which allows maltodextrin to form smooth, reflective surfaces. In contrast, freeze drying produces porous particles where maltodextrin has less impact on surface brightness. According to previous studies, the L* values of whey powder ranged from 90.9 to 91.63 in various regions (Sithole et al., 2005), and from 84.97 to 85.35 in freeze-dried whey powder (Culver and Wrolstad, 2008). These values are comparable to those observed in the present study. The current study also found that the freeze-dried powder exhibited a more greenish hue compared to the spray-dried powder. This is supported by previous research reporting a* values for whey powder ranging from -0.42 to -0.59 across various regions (Sithole et al., 2005), indicating a slight green hue. Another study reported a range of a* value from -1.50 to +1.75 under different environmental conditions in whey powder (Sithole et al., 2006), and -1.20 in milk powder (Deshwal et al., 2020). These findings are consistent to the results of current study. Furthermore, the current study revealed that the freeze dried powder appeared more yellowish than the spray dried powder. Previous studies have reported that the b* values in whey powder ranged from 8.6 to 24.5, while in milk powder, they ranged from 8.30 to 11.92, depending on various factors (Sithole et al., 2006).

The foaming capacity was measured immediately after homogenization (0 min), while foam stability was assessed at 30 and 60 min intervals.

-Bulk density

According to Fadila et al. (2025), bulk density was measured by placing approximately 2 g of whey powder into a 10 ml graduated cylinder and tapping it repeatedly (20–30 times) until the volume stabilized. The final settled volume was recorded, and bulk density was calculated using the following formula:

-Tapped density

The tapped density of the whey powder was measured following the standardized procedure outlined by Fadila et al. (2025). About 2 g of the powder sample was accurately placed into a clean, dry 10 ml graduated cylinder. The cylinder was then subjected to 100 controlled taps against a firm laboratory bench pad until the powder volume reached equilibrium (no further volume reduction). The final compacted volume was recorded after tapping, and the tapped density was calculated using the following formula:

-Carr’s index

Carr's index, an indicator of powder flowability and compressibility, was determined following the method of Fadila et al. (2025) using the equation:

-Hausner ratio

Hausner ratio, a parameter characterizing powder flowability, was calculated according to Fadila et al. (2025) using the following equation:

Statistical analysis

One-way Analysis of Variance (ANOVA) was conducted using the Statistical Package for the Social Sciences (SPSS) version 22.0 (SPSS Inc., Chicago, IL), followed by Duncan’s Multiple Range Test (DMRT) to determine significant differences at the 5% significance level (p< 0.05) with a 95% confidence interval.

Results and discussion

Chemical composition of whey powder

Table 1 illustrates notable differences in the chemical composition of whey powder produced by the two drying techniques.

Table 1: Chemical composition of whey powder (n=6)

Table 2: Physical properties of whey powder (n=6)

| Attributes | Spray dried powder | Freeze dried powder | |

| Color | L* | 93.75±0.36 a | 89.76±0.61 b |

| a* | -0.11±0.13 b | -2.885±0.14 a | |

| b* | 4.04±0.29 b | 16.51±0.68 a | |

Solubility (%) |

98.76±1.19 a |

98.87±0.26 a |

|

| Hygroscopicity (%) | 49.26±0.15 a | 49.06±0.80 a | |

| Wettability (second) | 154 a | 73 b | |

Values are mean±  Standard Deviation (SD) of three replicate. Different superscripts within the same row indicate a significant difference at p<0.05. L*=lightness; a*=red-green color Space; b*=yellow-blue color Space

Standard Deviation (SD) of three replicate. Different superscripts within the same row indicate a significant difference at p<0.05. L*=lightness; a*=red-green color Space; b*=yellow-blue color Space

Standard Deviation (SD) of three replicate. Different superscripts within the same row indicate a significant difference at p<0.05. L*=lightness; a*=red-green color Space; b*=yellow-blue color Space

Standard Deviation (SD) of three replicate. Different superscripts within the same row indicate a significant difference at p<0.05. L*=lightness; a*=red-green color Space; b*=yellow-blue color Space-Solubility

No significant difference was observed between spray-dried and freeze-dried whey powder (Table 2). The solubility of the powder can be significantly affected by the drying process as well as factors like maltodextrin content, particle size, surface area, and drying conditions. The solubility of whey powder observed in this study was higher than that reported in previous research. Previous research by Franceschinis et al. (2014) found that the drying method, whether spray drying or freeze drying, had no significant impact on the color of blackberry powder formulated with maltodextrin. Another study on freeze dried whey powder reported solubility ranging from 91.4 to 99.3% (Mavropoulou and Kosikowski, 1973), which is consistent with the findings of the present study. Lower moisture content is generally linked to higher solubility because it reduces stickiness and increases the surface area available for interaction with water during rehydration. However, in this study, solubility did not show a significant difference despite the variations in moisture content.

-Hygroscopicity

In this study, both spray drying and freeze drying, whey powders exhibited high hygroscopicity values (~49%), exceeding the generally threshold (Nurhad et al., 2012). This higher moisture sorption is likely due to the high lactose content in whey, which is inherently hygroscopic, especially in its amorphous state combined with the powders’ small particle size and large surface area that facilitate increased water absorption (Jyothi et al., 2022). Additionally, although maltodextrin was added as a drying aid to reduce stickiness and hygroscopicity, the relatively low concentration used (5%) may have been insufficient to significantly suppress moisture absorption, as higher molecular weight maltodextrins or larger amounts are often more effective (Bhusari et al., 2014). While previous studies have reported that freeze dried powders tend to be more hygroscopic than spray dried ones (Araújo et al., 2022), the current study observed no significant difference, likely due to comparable surface properties and maltodextrin incorporation in both drying methods. Further optimization of formulation or the use of additional carriers may help reduce hygroscopicity in future applications.

-Wettability

Wettability describes the capacity of whey powder to absorb liquids, a process mainly influenced by capillary forces. The freeze dried powder showed higher wettability than spray dried powder (Table 2). Wettability is influenced by various factors, including the type of carrier agent used (e.g., maltodextrin and its hygroscopic properties), the reconstitution temperature, and the powder’s particle size and shape. These factors have inverse relation to wettability. Larger powder particles have more spaces between them, making it easier for water to get through. Conversely, smaller particles have poorer reconstitution qualities because they are less porous (Santhalakshmy et al., 2015). The current findings revealed that the spray dried powder showed significantly lower wettability (p<0.05) even with its reduced bulk density relative to freeze dried powder. This variation may be due to differences in particle size, indicating a deviation from earlier findings. Caliskan and Dirim (2016) reported similar results in their study on the effects of spray and freeze drying on sumac extract powder. Consequently, the wettability of freeze-dried powder was higher than that of spray-dried powder.

Functional properties of whey powder

Table 3 displays the functional properties of whey powder prepared using spray drying and freeze drying techniques.

No significant difference was observed between spray-dried and freeze-dried whey powder (Table 2). The solubility of the powder can be significantly affected by the drying process as well as factors like maltodextrin content, particle size, surface area, and drying conditions. The solubility of whey powder observed in this study was higher than that reported in previous research. Previous research by Franceschinis et al. (2014) found that the drying method, whether spray drying or freeze drying, had no significant impact on the color of blackberry powder formulated with maltodextrin. Another study on freeze dried whey powder reported solubility ranging from 91.4 to 99.3% (Mavropoulou and Kosikowski, 1973), which is consistent with the findings of the present study. Lower moisture content is generally linked to higher solubility because it reduces stickiness and increases the surface area available for interaction with water during rehydration. However, in this study, solubility did not show a significant difference despite the variations in moisture content.

-Hygroscopicity

In this study, both spray drying and freeze drying, whey powders exhibited high hygroscopicity values (~49%), exceeding the generally threshold (Nurhad et al., 2012). This higher moisture sorption is likely due to the high lactose content in whey, which is inherently hygroscopic, especially in its amorphous state combined with the powders’ small particle size and large surface area that facilitate increased water absorption (Jyothi et al., 2022). Additionally, although maltodextrin was added as a drying aid to reduce stickiness and hygroscopicity, the relatively low concentration used (5%) may have been insufficient to significantly suppress moisture absorption, as higher molecular weight maltodextrins or larger amounts are often more effective (Bhusari et al., 2014). While previous studies have reported that freeze dried powders tend to be more hygroscopic than spray dried ones (Araújo et al., 2022), the current study observed no significant difference, likely due to comparable surface properties and maltodextrin incorporation in both drying methods. Further optimization of formulation or the use of additional carriers may help reduce hygroscopicity in future applications.

-Wettability

Wettability describes the capacity of whey powder to absorb liquids, a process mainly influenced by capillary forces. The freeze dried powder showed higher wettability than spray dried powder (Table 2). Wettability is influenced by various factors, including the type of carrier agent used (e.g., maltodextrin and its hygroscopic properties), the reconstitution temperature, and the powder’s particle size and shape. These factors have inverse relation to wettability. Larger powder particles have more spaces between them, making it easier for water to get through. Conversely, smaller particles have poorer reconstitution qualities because they are less porous (Santhalakshmy et al., 2015). The current findings revealed that the spray dried powder showed significantly lower wettability (p<0.05) even with its reduced bulk density relative to freeze dried powder. This variation may be due to differences in particle size, indicating a deviation from earlier findings. Caliskan and Dirim (2016) reported similar results in their study on the effects of spray and freeze drying on sumac extract powder. Consequently, the wettability of freeze-dried powder was higher than that of spray-dried powder.

Functional properties of whey powder

Table 3 displays the functional properties of whey powder prepared using spray drying and freeze drying techniques.

Table 3: Functional properties of whey powder (n=6)

| Parameters | Spray dried powder | Freeze dried powder | |

| Bulk density (g/cm3) | 0.57±0.02 a | 0.56±0.06 a | |

| Tapped density (g/cm3) | 0.80± 0.03 a | 0.83±0.03 a | |

| Carr’s index (%) | 28.75 b | 32.54 a | |

| Hausner ratio | 1.41 b | 1.48 a | |

| Flow-ability | Poor flow-ability | Very poor flow-ability | |

| Foaming capacity (%) | 7.83±1.26 b | 13.33±1.53 a | |

| Foaming stability (%) | 5 min | 5.33±1.25 b | 11.17±2.08 a |

| 10 min | 1.50±1 b | 6.83±3.78 a | |

Values are mean±  Standard Deviation (SD) of three replicate. Different superscripts within the same row indicate significant differences at p<0.05.

Standard Deviation (SD) of three replicate. Different superscripts within the same row indicate significant differences at p<0.05.

Standard Deviation (SD) of three replicate. Different superscripts within the same row indicate significant differences at p<0.05.

Standard Deviation (SD) of three replicate. Different superscripts within the same row indicate significant differences at p<0.05.-Bulk and tapped density

No significant differences were observed between the bulk and tapped densities of whey powder produced by spray drying and freeze drying (Table 3). These densities are primarily affected by factors such as particle size, shape, distribution, and interparticle attractive forces (Begum et al., 2017). Lower bulk density and higher amounts of trapped air within powders increase the risk of product oxidation and reduce storage stability (Koç et al., 2014). However, bulk and tapped density of whey powder in present study was higher than previous findings. Previous studies on hazelnut milk powder with 5% maltodextrin showed a bulk density of 0.301 g/cm3 and tapped density of 0.495 g/cm3 for spray dried powder, compared to a bulk density of 0.154 g/cm3 and tapped density of 0.224 g/cm3 for freeze dried powder (Ermis et al., 2018). In other studies, it was found that spray dried powder showed significantly higher bulk and tapped density than freeze dried powder (Begum et al., 2017; Deshwal et al., 2020), however, the current study demonstrates that there is no significant difference between them. Bulk and tapped densities of powder products influence their packaging, transportation, and compaction properties.

-Flowability

The flowability of powders or granular materials, a critical functional characteristic, can be quantified using both the Hausner ratio and Carr's index. Based on the Carr’s index and Hausner ratio criteria presented in Table 4, the spray-dried powder exhibited poor flowability, while the freeze-dried powder demonstrated very poor flowability (Fadila et al., 2025). Though powder from both drying techniques showed poor flowability, the current study revealed that spray dried powder unveils better flowability than freeze dried powder. This inconvenience may be due to its low moisture content, particle size distribution, and contact surface area in spray dried powder. According to the previous studies, similar report of drying effect were found on sumac extract powder (Caliskan and Dirim, 2016), and whole camel milk powder (Deshwal et al., 2020). The flowability of whey powders plays a crucial role in their processing efficiency (minimizing caking), product quality (consistent texture, easily blending), and overall operational performance. In this investigation, spray dried whey powder demonstrated comparatively superior flowability.

No significant differences were observed between the bulk and tapped densities of whey powder produced by spray drying and freeze drying (Table 3). These densities are primarily affected by factors such as particle size, shape, distribution, and interparticle attractive forces (Begum et al., 2017). Lower bulk density and higher amounts of trapped air within powders increase the risk of product oxidation and reduce storage stability (Koç et al., 2014). However, bulk and tapped density of whey powder in present study was higher than previous findings. Previous studies on hazelnut milk powder with 5% maltodextrin showed a bulk density of 0.301 g/cm3 and tapped density of 0.495 g/cm3 for spray dried powder, compared to a bulk density of 0.154 g/cm3 and tapped density of 0.224 g/cm3 for freeze dried powder (Ermis et al., 2018). In other studies, it was found that spray dried powder showed significantly higher bulk and tapped density than freeze dried powder (Begum et al., 2017; Deshwal et al., 2020), however, the current study demonstrates that there is no significant difference between them. Bulk and tapped densities of powder products influence their packaging, transportation, and compaction properties.

-Flowability

The flowability of powders or granular materials, a critical functional characteristic, can be quantified using both the Hausner ratio and Carr's index. Based on the Carr’s index and Hausner ratio criteria presented in Table 4, the spray-dried powder exhibited poor flowability, while the freeze-dried powder demonstrated very poor flowability (Fadila et al., 2025). Though powder from both drying techniques showed poor flowability, the current study revealed that spray dried powder unveils better flowability than freeze dried powder. This inconvenience may be due to its low moisture content, particle size distribution, and contact surface area in spray dried powder. According to the previous studies, similar report of drying effect were found on sumac extract powder (Caliskan and Dirim, 2016), and whole camel milk powder (Deshwal et al., 2020). The flowability of whey powders plays a crucial role in their processing efficiency (minimizing caking), product quality (consistent texture, easily blending), and overall operational performance. In this investigation, spray dried whey powder demonstrated comparatively superior flowability.

Table 4: Criteria for Carr’s index and Hausner ratio

| No. | Flowability | Carr's index (%) | Hausner ratio |

| 1 | Excellent | 0-10 | 1-1.11 |

| 2 | Good | 10-15 | 1.12-1.18 |

| 3 | Fair | 16-20 | 1.19-1.25 |

| 4 | Possible | 21-25 | 1.26-1.34 |

| 5 | Poor | 26-31 | 1.35-1.45 |

| 6 | Very poor | 32-37 | 1.46-1.49 |

| 7 | Very, very poor | >38 | >1.60 |

-Foaming properties

In many food and beverage applications, whey powder's stability and foaming ability are crucial considerations. Foaming properties of powders are influenced by various factors including protein fraction, surface characteristics, and film-forming abilities (Özdemir et al., 2022). Table 3 demonstrates the foaming capacity of spray dried and freeze dried whey powder showing values of 7.83±1.26 and 13.33±1.53%, respectively. A significant difference (p< 0.05) in foaming capacity was found between the drying methods, with freeze-dried whey powder showing higher foaming ability compared to spray-dried powder. The reduced performance of the spray dried powder may result from the greater damage to protein structure and surface activity caused by the drying process (Özdemir et al., 2022). Özdemir et al. (2022) reported foaming capacity results that are consistent with the findings of the present study. Another similar results were revealed by Zhao et al. (2013), where freeze dried powder showed higher foaming capacity than spray dried powder. Foaming stability measures how well a foam holds onto its shape and volume over time. Table 3 indicated that the foaming stability of freeze-dried whey powder was significantly higher (p<0.05) than that of spray-dried whey powder. Higher foaming stability for freeze dried powder might be due to more unfolding of the proteins, increasing their surface activity. Whereas, Deshwal et al. (2020) mentioned opposite explanation for both spray dried and freeze dried powder of whole camel milk powder. These findings could be valuable for food and beverage industries that utilize whey powder as an ingredient in products requiring foam formation and stability.

Conclusion

This comparative study highlights that drying methods and conditions significantly influence the overall quality of whey powder. Both spray dried and freeze dried powders were affected similarly by the addition of maltodextrin. While the spray dried powder exhibited superior chemical properties that may contribute to an extended shelf-life, its slightly elevated titratable acidity posed minimal concern regarding taste. The high protein content in both powders underscores their potential for human consumption, particularly in the food industry. Regarding physical property analysis, drying conditions significantly influenced the color of the powders, with freeze dried whey powder appearing more yellowish and greenish. Both powders demonstrated similar solubility and hygroscopicity, though spray dried whey powder exhibited lower wettability, Coupled with its enhanced flowability, these characteristics render it more suitable for food and pharmaceutical applications. In contrast, the freeze dried whey powder, with its superior foaming capacity and stability, is well-suited for specialized industrial and functional uses. Although freeze-dried powder exhibited superior functional properties, spray drying is preferred for whey powder production due to its higher stability, lower operational costs, faster drying time, and greater suitability for large-scale manufacturing. This stable processing technology has the potential to convert whey, a commonly wasted byproduct, into valuable, novel products, thereby advancing sustainable development goals through spray drying. Further research should look into the mineral composition, microbiological quality, shelf-life stability, and potential health benefits of cow whey powder supplementation.

Author contributions

R.B. designed the study; A.B.J., S.A. and N.I. conducted the experimental work; R.H. and M.I. analyzed the data and wrote the manuscript. All authors read and approved the final manuscript.

Acknowledgements

The authors express their sincere gratitude to the Department of Food Technology and Nutritional Science, Mawlana Bhashani Science and Technology University, Santosh, Tangail-1902, for providing the necessary logistical support to carry out this research.

Conclusion

This comparative study highlights that drying methods and conditions significantly influence the overall quality of whey powder. Both spray dried and freeze dried powders were affected similarly by the addition of maltodextrin. While the spray dried powder exhibited superior chemical properties that may contribute to an extended shelf-life, its slightly elevated titratable acidity posed minimal concern regarding taste. The high protein content in both powders underscores their potential for human consumption, particularly in the food industry. Regarding physical property analysis, drying conditions significantly influenced the color of the powders, with freeze dried whey powder appearing more yellowish and greenish. Both powders demonstrated similar solubility and hygroscopicity, though spray dried whey powder exhibited lower wettability, Coupled with its enhanced flowability, these characteristics render it more suitable for food and pharmaceutical applications. In contrast, the freeze dried whey powder, with its superior foaming capacity and stability, is well-suited for specialized industrial and functional uses. Although freeze-dried powder exhibited superior functional properties, spray drying is preferred for whey powder production due to its higher stability, lower operational costs, faster drying time, and greater suitability for large-scale manufacturing. This stable processing technology has the potential to convert whey, a commonly wasted byproduct, into valuable, novel products, thereby advancing sustainable development goals through spray drying. Further research should look into the mineral composition, microbiological quality, shelf-life stability, and potential health benefits of cow whey powder supplementation.

Author contributions

R.B. designed the study; A.B.J., S.A. and N.I. conducted the experimental work; R.H. and M.I. analyzed the data and wrote the manuscript. All authors read and approved the final manuscript.

Acknowledgements

The authors express their sincere gratitude to the Department of Food Technology and Nutritional Science, Mawlana Bhashani Science and Technology University, Santosh, Tangail-1902, for providing the necessary logistical support to carry out this research.

Conflicts of interest

The authors declare that there is no conflict of interest.

Funding

This research received no specific grant to conduct this research.

Ethical consideration

There were no human subject experiments in the study.

References

Araújo C.D.S., Vimercati W.C., Macedo L.L., Saraiva S.H., Teixeira L.J.Q., Da Costa J.M.G., Pimenta C.J. (2022). Encapsulation of phenolic and antioxidant compounds from spent coffee grounds using spray-drying and freeze-drying and characterization of dried powders. Journal of Food Science. 87: 4056-4067. [DOI: 10.1111/1750-3841.16281]

AOAC International. (2005). Official methods of analysis. 18th Edition. AOAC International. Gaithersburg, Maryland, USA. URL: https://www.researchgate.net/publication/292783651_AOAC_2005. Accessed 12 September 2024.

Babaei Rad S., Mumivand H., Mollaei S., Khadivi A. (2025). Effect of drying methods on phenolic compounds and antioxidant activity of Capparis spinosa L. fruits. BMC Plant Biology. 25: 133. [DOI: 10.1186/s12870-025-06110-y]

Begum R., Yusof Y.A., Aziz M.G., Uddin M.B. (2017). Structural and functional properties of pectin extracted from jackfruit (Artocarpus heterophyllus) waste: effects of drying. International Journal of Food Properties. 20: S190-S201. [DOI: 10.1080/10942912.2017.1295054]

Bhusari S.N., Muzaffar K., Kumar P. (2014). Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technology. 266: 354-364. [DOI: 10.1016/j.powtec.2014.06.038]

Buchanan D., Martindale W., Romeih E., Hebishy E. (2023). Recent advances in whey processing and valorisation: technological and environmental perspectives. International Journal of Dairy Technology. 76: 291-312. [DOI: 10.1111/1471-0307.12935]

Caliskan G., Dirim S.N. (2016). The effect of different drying processes and the amounts of maltodextrin addition on the powder properties of sumac extract powders. Powder Technology. 287: 308-314. [DOI: 10.1016/j.powtec.2015.10.019]

Chegini G., HamidiSepehr A., Dizaji M.F., Mirnezami S.V. (2014). Study of physical and chemical properties of spray drying whey powder. International Journal of Recycling of Organic Waste in Agriculture. 3: 62. [DOI: 10.1007/s40093-014-0062-2]

Codex Alimentarius Commission. (1995). Standard for whey powders: CXS 289-1995. URL: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/fr/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B289-1995%252FCXS_289e.pdf. Accessed 25 October 2024.

Coşkun N., Sarıtaş S., Jaouhari Y., Bordiga M., Karav S. (2024). The impact of freeze drying on bioactivity and physical properties of food products. Applied Sciences. 14: 9183. [DOI: 10.3390/app14209183]

Culver C.A., Wrolstad R.E. (2008). Color Quality of Fresh and Processed Foods. 983. American Chemical Society. Washington, DC. [DOI: 10.1021/bk-2008-0983]

Deshmukh N., Rao P.S., Sharma H., Sathish Kumar M.H., Laxmana Naik N., Manoj Kumar C.T. (2024). Waste to nutrition: The evolution of whey, a byproduct to galactooligosaccharides production. Food Chemistry Advances. 4: 100642. [DOI: 10.1016/j.focha.2024.100642]

Deshwal G.K., Singh A.K., Kumar D., Sharma H. (2020). Effect of spray and freeze drying on physico-chemical, functional, moisture sorption and morphological characteristics of camel milk powder. LWT. 134: 110117. [DOI: 10.1016/ j.lwt.2020.110117]

Ermis E., Güner K.Ö., Yilmaz M.T. (2018). Characterization of hazelnut milk powders: a comparison of spray-drying and freeze-drying. International Journal of Food Engineering. 14: 20180085. [DOI: 10.1515/ijfe-2018-0085]

Fadila A.N., Begum R., Hasan R., Haque A., Shuchy S.I., Aziz M.G. (2025). Evaluation of flowability and compressibility characteristics of composite moringa (Moringa oleifera) leaf and jackfruit (Artocarpus heterophyllus) bulb powder granules and tablets. Journal of Food Processing and Preservation. 2025. [DOI: 10.1155/jfpp/7701693]

FAO and WHO. (1999). Standard for milk powders and cream powder. Codex Alimentarius Standard, No. CXS 207-1999. Codex Alimentarius Commission. Rome. URL: https://www. fao.org/fao-who-codexalimentarius/sh-proxy/ua/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B207-1999%252FCXS_207e.pdf. Accessed 23 October 2024.

Franceschinis L., Salvatori D.M., Sosa N., Schebor C. (2014). Physical and functional properties of blackberry freeze- and spray-dried powders. Drying Technology. 32: 197-207. [DOI: 10.1080/07373937.2013.814664]

Gaspar F., Vicente J., Neves F., Authelin J.-R. (2014). Spray drying: scale-up and manufacturing. In: Shah N., Sandhu H., Choi D., Chokshi H., Malick A. (editors). Amorphous solid dispersions. Advances in Delivery Science and Technology. Springer. New York, NY. pp: 261-302. [DOI: 10.1007/978-1-4939-1598-9_8]

Goff H.D., Hynes E.H., Perotti M.C., Kelly P.M., Hogan S.A. (2022). Significance of lactose in dairy products. In: McSweeney P.L.H., O'Mahony J.A., Kelly A.L. (editors). Advanced dairy chemistry. Springer. Cham. pp: 39-104. [DOI: 10.1007/978-3-030-92585-7_3]

Güzeler N., Kalender M., Say D. (2017). Some properties of freeze-drying whey powders. Annals of the University of Craiova - Agriculture, Montanology, Cadastre Series. XLVII. 2017: 141-146.

Jyothi G.S., Manjunath R., Suresha K.B., Ambika D.S. (2022). Production of spray dried jackfruit powder from enzymatic liquefied juice. The Pharma Innovation Journal. 11: 1626-1633.

Koç B., Sakin-Yılmazer M., Kaymak-Ertekin F., Balkır P. (2014). Physical properties of yoghurt powder produced by spray drying. Journal of Food Science and Technology. 51: 1377-1383. [DOI: 10.1007/s13197-012-0653-8]

Kucharska-Guzik A., Guzik Ł., Charzyńska A., Michalska-Ciechanowska A. (2025). Influence of freeze drying and spray drying on the physical and chemical properties of powders from Cistus creticus L. extract. Foods. 14: 849. [DOI: 10.3390/foods14050849]

Kumar N., Vandana, Hati S. (2016). The four Fs for whey utilization. Beverage and Food World. 43: 28-31.

Mavropoulou I.P., Kosikowski F.V. (1973). Composition, solubility, and stability of whey powders. Journal of Dairy Science. 56: 1128-1134. [DOI: 10.3168/jds.S0022-0302(73)85321-4]

Nurhad B., Andoyo R., Mahani, Indiarto R. (2012). Study the properties of honey powder produced from spray drying and vacuum drying method. International Food Research Journal. 19: 907-912.

Oliveira S.M., Brandão T.R.S., Silva C.L.M. (2016). Influence of drying processes and pretreatments on nutritional and bioactive characteristics of dried vegetables: a review. Food Engineering Reviews. 8: 134-163. [DOI: 10.1007/s12393-015-9124-0]

Olvera-Rosales L.B., Cruz-Guerrero A.E., García-Garibay J.M., Gómez-Ruíz L.C., Contreras-López E., Guzmán-Rodríguez F., González-Olivares L.G. (2022). Bioactive peptides of whey: Obtaining, activity, mechanism of action, and further applications. Critical Reviews in Food Science and Nutrition. 63: 10351-10381. [DOI: 10.1080/10408398.2022.2079113]

Ozcelik M., Kulozik U. (2023). The role of maltodextrin concentration in maintaining storage stability of dried fruit foams texturized using plant protein–polysaccharide blends. Foods. 12: 1673. [DOI: 10.3390/foods12081673]

Özdemir E.E., Görgüç A., Gençdağ E., Yılmaz F.M. (2022). Physicochemical, functional and emulsifying properties of plant protein powder from industrial sesame processing waste as affected by spray and freeze drying. LWT. 154: 112646. [DOI: 10.1016/j.lwt.2021.112646]

Pinheiro V.D.S., Souza M.V.G.D., Oliveira G.V.D., Monteiro M.L.G., Aquino A., Conte-Junior C.A., Alvares T.S. (2024). Physicochemical and protein profile of goat whey powder. Ciência Rural. 54: e20220317. [DOI: 10.1590/0103-8478cr20220317]

Pui L.P., Saleena L.A.K. (2022). Effects of spray-drying parameters on physicochemical properties of powdered fruits. Foods and Raw Materials. 10: 235-251. [DOI: 10.21603/2308-4057-2022-2-533]

Rannou C., Queveau D., Beaumal V., David-Briand E., Le Borgne C., Meynier A., Anton M., Prost C., Schuck P., Loisel C. (2015). Effect of spray-drying and storage conditions on the physical and functional properties of standard and n−3 enriched egg yolk powders. Journal of Food Engineering. 154: 58-68. [DOI: 10.1016/j.jfoodeng.2014.11.002]

Santhalakshmy S., Bosco S.J.D., Francis S., Sabeena M. (2015). Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technology. 274: 37-43. [DOI: 10.1016/j.powtec.2015.01.016]

Sirmacekic E., Atilgan A., Rolbiecki R., Jagosz B., Rolbiecki S., Gokdogan O., Niemiec M., Kocięcka J. (2022). Possibilities of using whey wastes in agriculture: case of Turkey. Energies. 15: 9636. [DOI: 10.3390/en15249636]

Sithole R., McDaniel M.R., Goddik L.M. (2006). Physicochemical, microbiological, aroma, and flavor profile of selected commercial sweet whey powders. Journal of Food Science. 71: C157-C163. [DOI: 10.1111/j.1365-2621.2006.tb15611.x]

Sithole R., McDaniel M.R., Goddik L.M. (2005). Rate of Maillard browning in sweet whey powder. Journal of Dairy Science. 88: 1636-1645. [DOI: 10.3168/jds.S0022-0302(05)72835-6]

Tastemirova U., Ciprovica I., Shingisov A. (2020). The comparison of the spray-drying and freeze-drying techniques for camel milk: a review. Research for Rural Development. 35: 102-105. [DOI: 10.22616/rrd.26.2020.015]

Tsermoula P., Khakimov B., Nielsen J.H., Engelsen S.B. (2021). Whey - the waste-stream that became more valuable than the food product. Trends in Food Science and Technology. 118: 230-241. [DOI: 10.1016/j.tifs.2021.08.025]

Vasiljevic T., Duke M. (2015). Whey protein isolation: overview and membrane operations. In: Drioli E., Giorno L. (editors). Encyclopedia of membranes. Springer, Berlin, Heidelberg. [DOI: 10.1007/978-3-642-40872-4_2062-1]

Zhao Q., Xiong H., Selomulya C., Chen X.D., Huang S., Ruan X., Zhou Q., Sun W. (2013). Effects of spray drying and freeze drying on the properties of protein isolate from rice dreg protein. Food and Bioprocess Technology. 6: 1759-1769. [DOI: 10.1007/s11947-012-0844-3]

AOAC International. (2005). Official methods of analysis. 18th Edition. AOAC International. Gaithersburg, Maryland, USA. URL: https://www.researchgate.net/publication/292783651_AOAC_2005. Accessed 12 September 2024.

Babaei Rad S., Mumivand H., Mollaei S., Khadivi A. (2025). Effect of drying methods on phenolic compounds and antioxidant activity of Capparis spinosa L. fruits. BMC Plant Biology. 25: 133. [DOI: 10.1186/s12870-025-06110-y]

Begum R., Yusof Y.A., Aziz M.G., Uddin M.B. (2017). Structural and functional properties of pectin extracted from jackfruit (Artocarpus heterophyllus) waste: effects of drying. International Journal of Food Properties. 20: S190-S201. [DOI: 10.1080/10942912.2017.1295054]

Bhusari S.N., Muzaffar K., Kumar P. (2014). Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technology. 266: 354-364. [DOI: 10.1016/j.powtec.2014.06.038]

Buchanan D., Martindale W., Romeih E., Hebishy E. (2023). Recent advances in whey processing and valorisation: technological and environmental perspectives. International Journal of Dairy Technology. 76: 291-312. [DOI: 10.1111/1471-0307.12935]

Caliskan G., Dirim S.N. (2016). The effect of different drying processes and the amounts of maltodextrin addition on the powder properties of sumac extract powders. Powder Technology. 287: 308-314. [DOI: 10.1016/j.powtec.2015.10.019]

Chegini G., HamidiSepehr A., Dizaji M.F., Mirnezami S.V. (2014). Study of physical and chemical properties of spray drying whey powder. International Journal of Recycling of Organic Waste in Agriculture. 3: 62. [DOI: 10.1007/s40093-014-0062-2]

Codex Alimentarius Commission. (1995). Standard for whey powders: CXS 289-1995. URL: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/fr/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B289-1995%252FCXS_289e.pdf. Accessed 25 October 2024.

Coşkun N., Sarıtaş S., Jaouhari Y., Bordiga M., Karav S. (2024). The impact of freeze drying on bioactivity and physical properties of food products. Applied Sciences. 14: 9183. [DOI: 10.3390/app14209183]

Culver C.A., Wrolstad R.E. (2008). Color Quality of Fresh and Processed Foods. 983. American Chemical Society. Washington, DC. [DOI: 10.1021/bk-2008-0983]

Deshmukh N., Rao P.S., Sharma H., Sathish Kumar M.H., Laxmana Naik N., Manoj Kumar C.T. (2024). Waste to nutrition: The evolution of whey, a byproduct to galactooligosaccharides production. Food Chemistry Advances. 4: 100642. [DOI: 10.1016/j.focha.2024.100642]

Deshwal G.K., Singh A.K., Kumar D., Sharma H. (2020). Effect of spray and freeze drying on physico-chemical, functional, moisture sorption and morphological characteristics of camel milk powder. LWT. 134: 110117. [DOI: 10.1016/ j.lwt.2020.110117]

Ermis E., Güner K.Ö., Yilmaz M.T. (2018). Characterization of hazelnut milk powders: a comparison of spray-drying and freeze-drying. International Journal of Food Engineering. 14: 20180085. [DOI: 10.1515/ijfe-2018-0085]

Fadila A.N., Begum R., Hasan R., Haque A., Shuchy S.I., Aziz M.G. (2025). Evaluation of flowability and compressibility characteristics of composite moringa (Moringa oleifera) leaf and jackfruit (Artocarpus heterophyllus) bulb powder granules and tablets. Journal of Food Processing and Preservation. 2025. [DOI: 10.1155/jfpp/7701693]

FAO and WHO. (1999). Standard for milk powders and cream powder. Codex Alimentarius Standard, No. CXS 207-1999. Codex Alimentarius Commission. Rome. URL: https://www. fao.org/fao-who-codexalimentarius/sh-proxy/ua/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B207-1999%252FCXS_207e.pdf. Accessed 23 October 2024.

Franceschinis L., Salvatori D.M., Sosa N., Schebor C. (2014). Physical and functional properties of blackberry freeze- and spray-dried powders. Drying Technology. 32: 197-207. [DOI: 10.1080/07373937.2013.814664]

Gaspar F., Vicente J., Neves F., Authelin J.-R. (2014). Spray drying: scale-up and manufacturing. In: Shah N., Sandhu H., Choi D., Chokshi H., Malick A. (editors). Amorphous solid dispersions. Advances in Delivery Science and Technology. Springer. New York, NY. pp: 261-302. [DOI: 10.1007/978-1-4939-1598-9_8]

Goff H.D., Hynes E.H., Perotti M.C., Kelly P.M., Hogan S.A. (2022). Significance of lactose in dairy products. In: McSweeney P.L.H., O'Mahony J.A., Kelly A.L. (editors). Advanced dairy chemistry. Springer. Cham. pp: 39-104. [DOI: 10.1007/978-3-030-92585-7_3]

Güzeler N., Kalender M., Say D. (2017). Some properties of freeze-drying whey powders. Annals of the University of Craiova - Agriculture, Montanology, Cadastre Series. XLVII. 2017: 141-146.

Jyothi G.S., Manjunath R., Suresha K.B., Ambika D.S. (2022). Production of spray dried jackfruit powder from enzymatic liquefied juice. The Pharma Innovation Journal. 11: 1626-1633.

Koç B., Sakin-Yılmazer M., Kaymak-Ertekin F., Balkır P. (2014). Physical properties of yoghurt powder produced by spray drying. Journal of Food Science and Technology. 51: 1377-1383. [DOI: 10.1007/s13197-012-0653-8]

Kucharska-Guzik A., Guzik Ł., Charzyńska A., Michalska-Ciechanowska A. (2025). Influence of freeze drying and spray drying on the physical and chemical properties of powders from Cistus creticus L. extract. Foods. 14: 849. [DOI: 10.3390/foods14050849]

Kumar N., Vandana, Hati S. (2016). The four Fs for whey utilization. Beverage and Food World. 43: 28-31.

Mavropoulou I.P., Kosikowski F.V. (1973). Composition, solubility, and stability of whey powders. Journal of Dairy Science. 56: 1128-1134. [DOI: 10.3168/jds.S0022-0302(73)85321-4]

Nurhad B., Andoyo R., Mahani, Indiarto R. (2012). Study the properties of honey powder produced from spray drying and vacuum drying method. International Food Research Journal. 19: 907-912.

Oliveira S.M., Brandão T.R.S., Silva C.L.M. (2016). Influence of drying processes and pretreatments on nutritional and bioactive characteristics of dried vegetables: a review. Food Engineering Reviews. 8: 134-163. [DOI: 10.1007/s12393-015-9124-0]

Olvera-Rosales L.B., Cruz-Guerrero A.E., García-Garibay J.M., Gómez-Ruíz L.C., Contreras-López E., Guzmán-Rodríguez F., González-Olivares L.G. (2022). Bioactive peptides of whey: Obtaining, activity, mechanism of action, and further applications. Critical Reviews in Food Science and Nutrition. 63: 10351-10381. [DOI: 10.1080/10408398.2022.2079113]