Volume 11, Issue 4 (December 2024)

J. Food Qual. Hazards Control 2024, 11(4): 223-231 |

Back to browse issues page

Ethics code: No

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Benchabane G, Benchabane A, Benslimane A, Lamamra K, Yagoub M, Mahbubul I et al . Rheological Quality Control Tests of Commercial Strawberry Stirred Yogurt: Pseudo-chewing Process. J. Food Qual. Hazards Control 2024; 11 (4) :223-231

URL: http://jfqhc.ssu.ac.ir/article-1-1246-en.html

URL: http://jfqhc.ssu.ac.ir/article-1-1246-en.html

G. Benchabane

, A. Benchabane

, A. Benchabane

, A. Benslimane *

, A. Benslimane *

, K. Lamamra

, K. Lamamra

, M. Yagoub

, M. Yagoub

, I.M. Mahbubul

, I.M. Mahbubul

, K. Bekkour

, K. Bekkour

, A. Benchabane

, A. Benchabane

, A. Benslimane *

, A. Benslimane *

, K. Lamamra

, K. Lamamra

, M. Yagoub

, M. Yagoub

, I.M. Mahbubul

, I.M. Mahbubul

, K. Bekkour

, K. Bekkour

Laboratoire de Mécanique, Matériaux et Energétique (L2ME), Université de Bejaia, Targa Ouzemmour, 06000 Bejaïa, Algeria , abdelhakim.benslimane@univ-bejaia.dz

Full-Text [PDF 494 kb]

(445 Downloads)

| Abstract (HTML) (1163 Views)

Full-Text: (235 Views)

Rheological Quality Control Tests of Commercial Strawberry Stirred Yogurt: Pseudo-chewing Process

G. Benchabane 1, A. Benchabane 1, A. Benslimane 2[*]*, K. Lamamra 3, M. Yagoub 4,

I.M. Mahbubul 5, K. Bekkour 6

1. Laboratoire de Génie Energétique et Matériaux, LGEM, Université de Biskra, B.P. 145, 07000 Biskra, Algeria.

2. Laboratoire de Mécanique, Matériaux et Energétique (L2ME), Université de Bejaia, Targa Ouzemmour, 06000 Bejaïa, Algeria.

3. Plateau Technique d'Analyse Physico-Chimiques -Biskra-CRAPC, El Hadjeb, Biskra, Algeria.

4. Hydraulic Development and Environment Laboratory, University of Biskra, 07000, Biskra, Algeria.

5. Institute of Energy Engineering, Dhaka University of Engineering & Technology, Gazipur 1707, Bangladesh.

6. ICube Mechanical Department, CNRS/University of Strasbourg, 67000 Strasbourg, France.

HIGHLIGHTS

To cite: Benchabane G., Benchabane A., Benslimane A., Lamamra K., Yagoub M., Mahbubul I.M., Bekkour K. (2024). Rheological quality control tests of commercial strawberry stirred yogurt: pseudo-chewing process. Journal of Food Quality and Hazards Control. 11: 223-231.

Introduction

G. Benchabane 1, A. Benchabane 1, A. Benslimane 2[*]*, K. Lamamra 3, M. Yagoub 4,

I.M. Mahbubul 5, K. Bekkour 6

1. Laboratoire de Génie Energétique et Matériaux, LGEM, Université de Biskra, B.P. 145, 07000 Biskra, Algeria.

2. Laboratoire de Mécanique, Matériaux et Energétique (L2ME), Université de Bejaia, Targa Ouzemmour, 06000 Bejaïa, Algeria.

3. Plateau Technique d'Analyse Physico-Chimiques -Biskra-CRAPC, El Hadjeb, Biskra, Algeria.

4. Hydraulic Development and Environment Laboratory, University of Biskra, 07000, Biskra, Algeria.

5. Institute of Energy Engineering, Dhaka University of Engineering & Technology, Gazipur 1707, Bangladesh.

6. ICube Mechanical Department, CNRS/University of Strasbourg, 67000 Strasbourg, France.

- Stirred yogurt showed a shear-thinning flow behavior with viscoelastic and thixotropic proprieties.

- An experimental procedure was developed that described rheological quality control tests of commercial strawberry stirred yogurt.

- Proposed procedures successfully simulate pseudo-chewing by offering rheological characteristics of yogurt during oral mastication.

| Article type Original article |

ABSTRACT

Background: The rheological behavior of yogurt plays a crucial role in determining the quality of the product. This study aimed to develop a rheological quality control test replicating pseudo-chewing using experimental rheological protocols.

Methods: The strawberry stirred yogurt sample was produced, in a 90 g pot, and commercialized in April 2023 by SOUMMAM dairy products, Bejaia, Akbou, Algeria. Rheological properties of a 0.6 ml yogurt sample were evaluated for each test measurement using a rheometer with a cone/plate geometry at a constant temperature of 25±0.1 °C. The shear flow experimental protocol involved three steps: a shear rate ramp, followed by a plateau at the maximum shear rate for 15 min, and afterward the ramp was reversed to measure the downward flow curve. The viscoelastic properties were evaluated by two experimental protocols in the Linear Viscoelastic Region. These properties were studied under oscillatory frequencies (0.1-100 Hz) with and without pre-shearing at 400 1/s for 15 min to simulate the pseudo-chewing process. All experimental data were analyzed and fitted using MS Excel and MS Excel Solver.

Results: The stirred yogurt samples showed a non-Newtonian viscoelastic flow behavior with thixotropy. Both upward and downward shear rate flow curves of the sample exhibited shear-thinning behavior described by the Herschel-Bulkley model with high regression coefficient of R2=0.98 and 0.99, respectively. Dynamic measurements showed that pseudo-chewing causes considerable changes in rheological parameters such as complex modulus, complex viscosity, and loss tangent. The pre-shearing altered complex modulus and complex viscosity, corresponding to an alteration in the yogurt’s firmness and flow properties.

Conclusions: The rheological procedures suggested in the present study can be used as rheological quality control tests of commercial strawberry stirred yogurt. This procedure can successfully simulate pseudo-chewing by offering information on the flow and viscoelastic characteristics of yogurt in the mouth during mastication.© 2024, Shahid Sadoughi University of Medical Sciences. This is an open access article under the Creative Commons Attribution 4.0 International License. |

|

| Keywords Rheology Quality Control Yogurt Mastication |

|

| Article history Received: 16 Jul 2024 Revised: 10 Oct 2024 Accept: 03 Dec 2024 |

|

Introduction

The planning and implementation of flow operations, quality assurance, stability during storage, and processing, texture prediction, and understanding microstructural changes in food products all depend on their rheological characteristics (Diamante and Umemoto, 2015; Flores-Jiménez et al., 2023; Heldman et al., 2006). Generally, milk-based products exhibit viscoelastic characteristics as well as time-dependent and shear-thinning flow behaviors. However, these food items are produced with diverse compositions implying evident variations in their rheological characteristics (Aguilar-Raymundo and Vélez-Ruiz, 2018; Szwajgier and Gustaw, 2015; Zarzycki et al., 2019). Among these milk-based products, stirred yogurt has been widely reported in the literature, particularly regarding its rheological properties (Guénard-Lampron et al., 2019, 2020; Ouyang et al., 2024).

Yogurt is a healthy dairy product that is extensively manufactured through a standard process as a liquid/semi-solid food. The inclusion of starter cultures causes a number of biological modifications in the dairy products; converting them into various intermediate products before achieving the required three-dimensional consistency or texture (Ahmed et al., 2023). Given their strong correlation with desired qualities, including flowability, firmness, and smoothness, the internal structure and rheological properties of yogurt are critical when evaluating the quality of the final product (Atik et al., 2024). The rheological properties of yogurt are mainly affected by solids, protein, fat content, temperatures during heat treatment of milk and fermentation, homogenization pressure, etc. (Mathias et al., 2011).

Generally, the rheological properties of liquid and semi-solid foods may influence oral processing behavior (Aguayo-Mendoza et al., 2019). Research has shown that these properties impact the complex dynamic process of mastication (Chen and Lolivret, 2011), which is essential for both food intake and sensory perception, ultimately influencing consumer acceptance. In addition to shear flow measurements, oscillatory shear tests are widely employed to assess the viscoelastic characteristics of food systems (Ahmed, 2018; Melito et al., 2012; Toker et al., 2013). These tests involve subjecting samples to frequency/stress sweep, allowing for the characterization of both elastic (storage modulus, G') and viscous (loss modulus, G'') components of the material’s response to deformation.

Despite extensive investigations into the influence of rheological properties on oral processing behavior, there is a notable gap in research regarding how the rheological properties of food are affected by the process of chewing. To address this gap, this study employs experimental protocols designed to simulate the process of chewing (mastication), mirroring the sequential phases involved in human food manipulation within the mouth. These protocols allow us to replicate the dynamic nature of the chewing process, without taking into account the effect of saliva, from the initiation of forces upon the food to the gradual breakdown of food particles and eventual cessation of chewing motion. These sequential phases are replicated in this experimental setup to investigate how the rheological properties of a commercial strawberry stirred yogurt are influenced by the pseudo-chewing process. This method provides more information about how yogurt behaves in situations that closely resemble oral processing, which could assist in product development and advance our knowledge of how people perceive food texture.

Materials and methods

Studied material

The present investigation was carried out at the Technical Platform of Physico-Chemical Analysis (TPPCA) at the University pole El-Hadjeb Biskra, Algeria. Commercial strawberry stirred yogurt, in a 90 g pot; was produced and marketed in April 2023 by SOUMMAM dairy products, Bejaia, Akbou, Algeria. The main composition of this yogurt includes whole milk, reconstituted whole milk, sugar, food additives identified by the International Numbering System (1,442 thickener: Good Manufacturing Practice (GMP); 129 colorants: 0.54 mg), strawberry flavor, and Lactobacillus yeasts. Additionally, the average nutritional values per 100 g of the strawberry-stirred yogurt sample were provided by the producer as shown in Table 1.

Table 1: Average nutritional values of the commercial strawberry stirred yogurt given by the producer

Rheological measurements

All the rheological measurements were performed using a controlled stress rheometer (Discovery HR 20, TA instruments, France). The rheometer is equipped with a cone and plate geometry (diameter 40 mm; angle 2°), and a stainless steel Peltier plate at a controlled temperature of 25±0.1 °C. The yogurt samples were used in their commercial form. A total of 0.6 ml of yogurt sample was used for each test measurement. The rheological properties of yogurt were studied under large (model parameters and thixotropy) and small (storage G′, loss G″ modulus, and complex viscosity) deformations. All experimental data were analyzed and fitted using MS Excel and MS Excel Solver.

To avoid any alteration to the solution structure, the sample was meticulously placed on the rheometer’s measurement plate, and the upper plate was then progressively lowered into the correct position. When the samples are positioned within the measurement geometry, their structural condition is influenced by their history of shear deformation and can appear to be ambiguous. To prevent any memory influence and to ensure measurement reproducibility, the samples must be in the same initial state, often known as the ‘reference state’.

Shear flow measurements (Protocol F)

Protocol F is accomplished in four experimental steps:

Step 1: first, the sample was positioned under the measurement geometry before applying a pre-shear rate of 10 s at 10 1/s. The aim of this step is to improve the reliability of experimental results by limiting possible memory effects of the sample. To promote restoration of its initial structure, the sample underwent a five min resting period post-pre-shearing, thus minimizing the influence of any transient effects and ensuring a more accurate representation during subsequent measurements.

Step 2: the typical experimental procedure involved three sequential steps, starting with 15 min of applied shear rate ramp from 1/105 to 400 1/s. This linearly increasing ramp of shear rate allowed forming the ascending part (upward) of the flow curve.

Step 3: in this step, the system reached a plateau known as the peak hold phase. During the peak hold phase, the samples were maintained at the maximum shear rate for 15 min. This step enabled observation of material behavior under sustained shear rate conditions.

Step 4: in this phase, the rheometer reversed the ramp, with the applied shear rate linearly decreasing from 400 to 1/105 1/s to measure the downward flow curve. This step completed the comprehensive characterization of the material rheological behavior under decreasing shear rates.

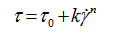

Both upward and downward rheogrammes are fitted by a Herschel-Bulkley rheological model using MS Excel Solver. The Herschel-Bulkley model is expressed in equation 1 (Vukić et al., 2018):

(1)

(1)

Where is the shear stress (Pa); 0 is the yield stress (Pa); γ ̇ is the shear rate (1/s); k is the consistency coefficient (Pa.sn), and n is the flow behavior index signifying the extent of deviation from Newtonian behavior. The Herschel-Bulkley model was selected due to its ease of use and capacity to measure yield stress. In addition, this model is recognized as one among several models available in the literature, commonly used to describe the rheological flow curves of various food products (Martínez-Padilla, 2024). For example, it has been used to model experimental rheological flow curves of chocolate (Kouřilová et al., 2022) and yogurt during production (Mullineux and Simmons, 2007, 2008).

Dynamic rheological measurements

Dynamic oscillatory measurements were used to determine the viscoelastic properties of stirred yogurt in the linear viscoelastic region in a pre-yield state. The dynamic tests were carried out before and after shearing the sample at a shear rate of 400 1/s for 15 min to study the effect of the pseudo-chewing process on yogurt in the mouth. For the oscillatory mode, two protocols were considered:

-Protocol D1

The sample was first loaded into the measuring device, and then the protocol D1 was executed in four steps:

Step 1: the sample was pre-sheared for 10 s at an imposed shear rate of 10 1/s to control the memory effect. Subsequently, the sample was rested for five min before starting the experiment to establish thermal equilibrium and relieve additional stresses caused by the loading.

Step 2: since the rheometer used in this study is an imposed stress rheometer, the controlled shear stress approach was selected as a mode of operation for presetting the deflection. A stress sweep test was performed at an angular frequency of 10 rad/s; the stress was varied from 0.01 to 100 Pa in order to determine the linear viscoelastic region.

-Protocol D2

Step 1: to eliminate any potential internal tensions in the sample prior to measurement, it was pre-sheared for 10 s at an imposed shear rate of 10 1/s, followed by five min of rest.

Step 2: as in protocol D1, the shear stress approach was selected for presetting the deflection. The frequency sweep test was performed using a shear stress amplitude of 0.2 Pa, within the linear viscoelastic region, obtained using protocol D1. These dynamic oscillatory tests were performed, with a frequency range of 0.1 to 100 Hz, to evaluate storage (G′), loss (G″), complex modulus (G*), and mixed dynamic viscosity (η*).

Step 3: shearing sample at a shear rate of 400 1/s for 15 min.

Step 4: this step is similar to step (2), launched after shearing the sample, i.e., after the simulated pseudo-chewing process.

Results and discussions

Shear flow analysis

The experimental protocol F employed in this study serves to simulate the process of chewing (mastication), without taking into account the effect of saliva, akin to how humans manipulate food within their mouths. In the act of pseudo-chewing, individuals initiate the process by exerting forces on the food as they begin to consume it. These initial forces are gradually increased to break down the food particles, mimicking the early stages of mastication. Subsequently, a plateau phase is reached during which the applied forces are sustained to thoroughly grind and process the food. Finally, the forces are gradually reduced and eventually ceased, representing the termination of the pseudo-chewing motion. These sequential phases were replicated within the experimental setup with the aim of capturing the dynamic nature of the pseudo-chewing process. This approach allows us to investigate how the rheological properties of yogurt are influenced by pseudo-chewing. Understanding these interactions can offer valuable insights into yogurt’s behavior under conditions that closely mimic oral processing, potentially informing product formulation and enhancing our understanding of food texture perception.

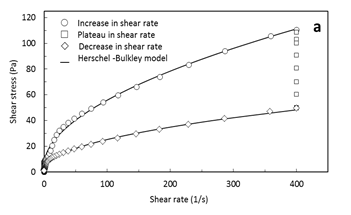

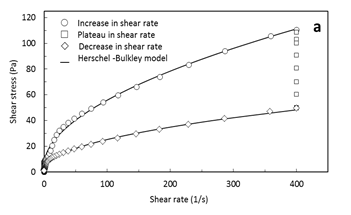

In this study, the rheological behavior of the material was examined by applying Protocol F, where shear stress and apparent viscosity were plotted as functions of the applied shear rate. The exploration of thixotropic properties was conducted by analyzing the hysteresis loop areas generated during a three-step experiment encompassing the upward curve, plateau, and downward curve phases. The flow curves of strawberry stirred yogurt, i.e., shear stress () as a function of shear rate (γ ̇), studied at 25±0.1 °C, are presented in Figure 1 as open points. The examined yogurt rheological flow curves displayed a clear yield stress and a hysteresis loop. The area between the curves measures the extent and time-dependent nature of thixotropy in the sample. The calculated thixotropy index of stirred yogurt is 48% (Figure 1), indicating the energy needed to break the reversible microstructure of the tested material. This result is similar to the findings obtained by Vukić et al. (2018) who reported a coefficient of thixotropic breakdown of 66% for the yogurt sample. Thus, the flow curves in Figure 1 lead to conclude that strawberry stirred yogurt is a yield stress non-Newtonian fluid with shear-thinning and thixotropic time-dependent flow characteristics.

Both upward and downward shear stress curves in Figure 1 are well described by Herschel-Bulkley rheological law with R2>0.98, presented by solid lines. The Herschel-Bulkley model shown in equation 1, and the values of its parameters were calculated (Vukić et al., 2018).

.PNG)

Figure 1: Flow behavior curves of strawberry stirred yogurt according to the protocol F; (a): linear plot; (b): logarithmic plot

Table 2 presents the values of the rheological parameters obtained from fitting the Herschel-Bulkley model. As shown in Table 2, the flow index value (n) of the yogurt, obtained from fitting the Herschel-Bulkley model, ranged from 0 to 1, indicating that the rheological behavior of the strawberry stirred yogurt sample is shear-thinning (n<1), thereby affirming its non-Newtonian and shear-thinning nature. The yield stress, defined as the lowest stress value necessary to cause the material to flow (De Souza Mendes and Thompson, 2012), was identified as the starting point of the flow curves. The yield stress difference between increasing and decreasing ramps for yogurt, as shown in Table 2, is attributed to structural breakdown induced by the applied shear rate during the experimental test. Since yogurt exhibits pseudoplastic and thixotropic rheological properties, applying shear rate leads to breakdown of its internal structure, which can be restructured by allowing the fluid to rest. Consequently, the yield stress encountered during the increasing ramp of 5 Pa is higher than that obtained during the decreasing ramp of 1 Pa. After pre-shearing the sample, a decrease in the consistency coefficient of yogurt was observed, which is a consequence of structural breakdown during the shearing process. Similar flow behavior has been reported by other researchers for yogurt (Gilbert and Turgeon 2021; Javanmard et al., 2018; Najgebauer-Lejko et al., 2020).

Table 2: The Herschel-Bulkley parameters of strawberry stirred yogurt sample

A product is subjected to a variety of shear rates throughout industrial activities, and to properly design the equipment for these procedures, it is crucial to understand how the viscosity changes with shear rates (Álvarez et al., 2006). In other words, viscosity is one of the key quality parameters affecting sensory characteristics of fermented dairy products (Vukić et al., 2018).

It is critical to characterize the time-dependent rheological properties of food systems to build connections between flow and structure, and to link physical characteristics with sensory assessment. The viscosity of stirred yogurt as a function of shear rate is presented in Figure 2. The experimental results are also presented in Figure 1. As the shear rate increases, the viscosity decreases, which can be explained by the material structure reorganizing at a greater shear rate. Initially, as the shear rate increases, viscosity decreases, indicating the pseudoplastic behavior of the material. Notably, viscosity decreases even during the plateau phase when the shear rate remains unchanged. This phenomenon suggests ongoing structural breakdown within the yogurt, which contributes to diminishing viscosity. The decreasing viscosity of yogurt may be attributed to the continuous structural breakdown. This behavior is attributed to the thixotropic nature of yogurt, wherein the internal structure undergoes reformation following shear-induced breakdown. Moreover, viscosity exhibits greater values (0.85 Pa.s at shear rate of 50 1/s) during the shear rate ascending ramp as opposed to the lowering ramp (0.37 Pa.s at shear rate of 50 1/s). This disparity underscores the impact of shear history on yogurt rheology, with the structured sample exhibiting greater resistance to flow than to the destructured sample.

In the medical field, the International Dysphagia Diet Standardization Initiative (IDDSI) framework includes specific terms for food liquids that correlate them with viscosity ranges measured at 25 °C and a shear rate of 50 1/s. This mean value corresponds to the shear rate in the oral cavity. The classifications are as follows: Thin liquids with viscosities ranging from 1/103 to 0.05 Pa.s, nectar-like liquids ranging from 0.05 to 0.35 Pa.s, honey-like liquids ranging from 0.35 to 1.75 Pa.s, and spoon-thick liquids with viscosities greater than 1.75 Pa.s (National Dysphagia Diet Task Force and American Dietetic Association, 2002; Poursani and Razavi, 2023). In this study, viscosities measured at a shear rate of 50 1/s are 0.85 and 0.37 Pa.s during increasing and decreasing ramps, respectively. Therefore, the viscosities, ranging between 0.35 and 1.75 Pa.s, can classify the studied strawberry stirred yogurt as a honey-like semisolid food. This result confirms findings by Vukić et al. (2018), who reported apparent yogurt viscosities between 0.41 and 0.60 Pa.s; thus the product was also classified as honey-like.

Figure 2: Variation of viscosity as a function of shear rate for strawberry stirred yogurt according to protocol F

Dynamic rheological analysis

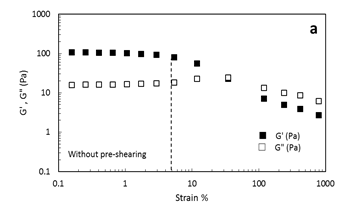

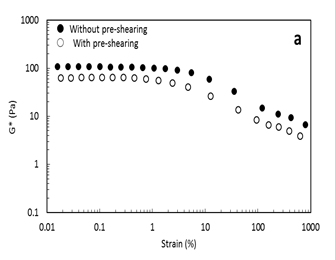

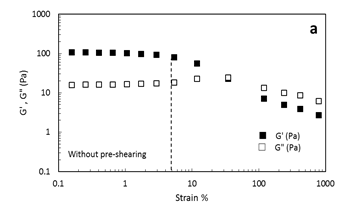

In viscoelasticity measurements, it is crucial to operate within the linear viscoelastic region to study the material in a structured state close to its resting state. The material is thus easily deformed, while its internal structure remains intact, with the applied stresses sufficiently low to prevent the rupture of inter-particle bonds. To ensure this, preliminary tests are necessary to define the ranges of applied stresses and the corresponding deformations for given stresses. Figure 3 illustrates measurements used to determine the linear viscoelastic region of the sample according to protocol D1. Stress sweeps are performed, between 0.01 and 100 Pa, while fixing the frequency at 1.6 Hz, and the resulting deformations are measured. This allows for establishing the linear viscoelastic region, or the stress range for which G' and G'' respond linearly.

Figures 3a and b illustrate the evolution of storage modulus (G') and loss modulus (G''), as functions of oscillation strain, respectively without and with pre-shearing of the sample to simulate the pseudo-chewing process. The values of these different parameters are higher without pre-shearing the sample. The strain at which the sample transitions from elastic to viscous behavior is also higher without pre-shearing compared to when no pre-shear is applied. This difference can be attributed to breakdown of the structured nature of the sample induced by shearing. When pre-shear is applied, the internal structure of the sample is disrupted, making it more susceptible to transitioning into the viscous domain under lower stress levels. Consequently, less force is required to induce transition into the viscous domain.

Moreover, the plateaus in storage modulus G' and loss modulus G'' are observed in Figures 3a and b with G' value higher than G''. These observations indicate typical behavior of viscoelastic materials such as gels and dispersions (Eroglu et al., 2016; Zarzycki et al., 2019). However, transition to the viscous domain occurs at these same levels of oscillation strain of one and five percent. A loss of linearity in moduli G' and G'' is observed, followed by a crossover, where storage modulus G' values become lower than loss modulus G''.

.PNG)

Figure 3: Oscillation strain limit of the linear viscoelastic region of strawberry stirred yogurt using the protocol D1 with an angular frequency of 10 rad/s (~1.6 Hz); variation of G' and G''as functions of oscillation strain; (a): without, and (b): with pre-shearing

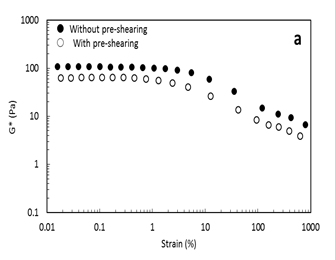

Figure 4a and b show the evolution of complex modulus (G*) and complex viscosity (η*) as functions of strain without and with pre-shearing of the sample, respectively, according to the protocol D1. The values of complex modulus and complex viscosity are lower for the sample that underwent pre-shear test compared to the non pre-sheared sample.

.PNG)

Figure 4: Evolution of (a): complex modulus (G*), and (b): complex viscosity (η*) as functions of strain without and with pre-shearing of strawberry stirred yogurt (using the protocol D1 with an angular frequency of 10 rad/s (~1.6 Hz))

The viscoelastic characteristics of the studied stirred yogurt were determined using the frequency sweep technique. The experimental data obtained are presented as the evolution of storage modulus (G′), loss modulus (G″), complex modulus (G*), complex viscosity (η*), and loss tangent (tan δ) as functions of frequency. In a standard oscillatory experimental test, referred to as a frequency sweep, the stirred yogurt samples were exposed to an increasing frequency range from 0.1 to 100 Hz while the shear stress amplitude was maintained at 0.2 Pa.

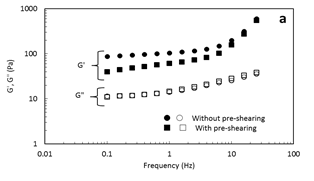

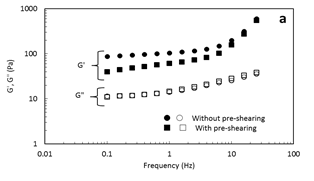

All samples exhibited frequency-dependent behavior, with both storage modulus (G') and loss modulus (G'') increasing as the frequency increased (Figure 5a). This frequency-dependent response is characteristic of viscoelastic materials (Vukić et al., 2018), where the material’s ability to store and dissipate energy varies with the rate at which it is subjected to oscillatory forces. The frequency dependence observed in both storage modulus (G') and loss modulus (G'') of the samples signifies their classification as physical gels. Physical gels typically exhibit pronounced frequency dependence. This frequency dependence suggests that the yogurt samples possess a network structure capable of storing and dissipating energy typical of physical gels. G' was larger than G'' at all investigated frequencies, suggesting that the stirred yogurt is a solid viscoelastic material.

The characterization of the samples as physical gels, based on the frequency dependence of their storage and loss moduli, is further supported by loss tangent analysis. The loss tangent serves as a widely recognized metric for elucidating the viscoelastic behavior of materials, providing insight into their inherent viscous or elastic properties. A loss tangent greater than one indicates liquid viscoelastic behavior, where the sample exhibits more viscous characteristics. Conversely, a loss tangent lower than one suggests solid viscoelastic behavior, indicative of more elastic properties. Figure 5b shows the evolution of loss tangent as a function of frequency. The loss tangent of the studied samples of stirred yogurt was lower than one at all investigated frequencies, indicating their solid viscoelastic behavior and confirming the results shown in Figure 5a.

To explore the pseudo-chewing process, two samples were examined: one underwent pre-shearing, whereas the other did not. As anticipated, storage modulus (G') and loss modulus (G'') magnitudes as a function of frequency for the pre-sheared sample were lower than those for the sample without pre-shear (Figure 5a). This reduction in modulus magnitudes suggests that pre-shearing resulted in internal structural breakdown within the sample, leading to decreased resistance to deformation. However, the magnitude of loss tangent for the pre-sheared sample was higher than that for the sample without pre-shear (Figure 5b).

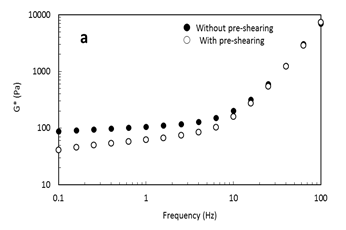

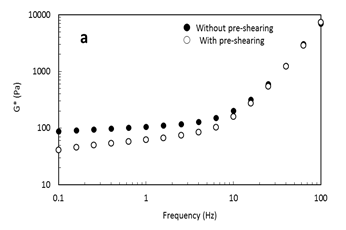

Figures 6a and b depict the evolution of G* (complex modulus) and η* (complex viscosity) as functions of frequency. It is evident that as frequency increases, G* also increases, indicating a frequency-dependent behavior (Figure 6a). This observation aligns with previous findings regarding the frequency dependence of G' and G'' (Figure 5a), suggesting that G* exhibits similar behavior. However, the same figure shows that applying pre-shear to a sample of stirred yogurt results in a decrease in G*, indicating a reduction in the material's overall firmness.

Notably, Figure 6b shows that the complex viscosity (η*) decreases as frequency increases. This phenomenon signifies that the material exhibits less resistance to flow at higher frequencies. Furthermore, the viscosity of the sample subjected to pre-shear is lower than that of the sample which is not subjected to pre-shear. This indicates that pre-shearing induces a reduction in viscosity due to internal structural breakdown within the sample.

.PNG)

Figure 5: Frequency sweep of strawberry stirred yogurt sample without and with pre-shearing according to the protocol D2; (a): storage and loss moduli (G' and G''); (b): loss tangent (tan δ)

.PNG)

Figure 6: The viscoelastic proprieties of strawberry stirred yogurt (frequency sweep) without and with pre-shearing according to the protocol D2; a: complex modulus (G*); b: complex viscosity (η*)

Conclusion

This study investigated the impact of the chewing process, without taking into account the effect of saliva, on the rheological properties of stirred commercial yogurt. By utilizing both steady and dynamic tests, the mechanical behavior of yogurt samples under pseudo-chewing was analyzed. The flow curves analysis revealed non-Newtonian shear-thinning behavior and time-dependent (thixotropic) properties of the stirred yogurt, while dynamic test demonstrated its viscoelastic properties.

Simulating the pseudo-chewing process through the chosen experimental protocols uncovered a notable decrease in viscosity, attributed to the destruction of internal structure of the yogurt. The findings indicate significant alterations in rheological parameters such as complex modulus (G*), complex viscosity (η*), and loss tangent (tan δ) in response to the pseudo-chewing process. Notably, pre-shearing induced changes in G* and η*, indicating modifications in the firmness and flow characteristics of the yogurt that affect its sensory properties. These findings contribute to improved product formulation and texture optimization by enhancing our understanding of the mechanical responses of yogurt during the pseudo-chewing process. This knowledge can assist producers in modifying their products to make them safer, easier to swallow, and more palatable. Furthermore, expanding the study to include a broader range of yogurt formulations and other food products would help generalize these findings.

Author contributions

A.B. and K.B. designed the study; G.B., A.B., K.L., and M.Y. conducted the experimental work; G.B., A.B., A.B., K.L., M.Y., I.M.M., and K.B. analyzed the data; A.B. and A.B. wrote, reviewed, and edited the manuscript. A.B. supervised the research. All authors read and approved the final manuscript.

Conflicts of Interest

The authors declare that there is no conflict of interest.

Acknowledgements

The authors wish to thank the director of the Plateau Technique d'Analyse Physico-Chimiques (Biskra-CRAPC), Professor Abderrezak Debilou, for his active support.

Funding

This study is a part of PRFU project A11N01UN070120220002 registered in the Directorate General of Scientific Research and Technological Development (DGRSDT) of the Algerian Ministry of Higher Education and Scientific Research. This research did not receive any specific grant from funding agencies.

Ethical consideration

Not applicable.

References

Aguayo-Mendoza M.G., Ketel E.C., Van Der Linden E., Forde C.G., Piqueras-Fiszman B., Stieger M. (2019). Oral processing behavior of drinkable, spoonable and chewable foods is primarily determined by rheological and mechanical food properties. Food Quality and Preference. 71: 87-95. [DOI: 10.1016/j.foodqual.2018.06.006]

Aguilar-Raymundo V.G., Vélez-Ruiz J.F. (2018). Physicochemical and rheological properties of a dairy dessert, enriched with chickpea flour. Foods. 7: 25. [DOI: 10.3390/foods7020025]

Ahmed J. (2018). Advances in rheological measurements of food products. Current Opinion in Food Science. 23: 127-132. [DOI: 10.1016/j.cofs.2018.10.007]

Ahmed J., Barua S., Roy S. (2023). Rheology and microstructure of yogurt. In: Ahmed J., Basu S. (Editors). Advances in food rheology and its applications. Woodhead Publishing, Sawston, Cambridge. pp: 335-363. [DOI: 10.1016/B978-0-12-823983-4.00020-0]

Álvarez E., Cancela M.A., Maceiras R. (2006). Effect of temperature on rheological properties of different jams. International Journal of Food Properties. 9: 135-146. [DOI: 10.1080/10942910500473996]

Atik D.S., Öztürk H.İ., Akın N. (2024). Perspectives on the yogurt rheology. International Journal of Biological Macromolecules. 263: 130428. [DOI: 10.1016/j.ijbiomac.2024.130428]

Chen J., Lolivret L. (2011). The determining role of bolus rheology in triggering a swallowing. Food Hydrocolloids. 25: 325-332. [DOI: 10.1016/j.foodhyd.2010.06.010]

De Souza Mendes P.R., Thompson R.L. (2012). A critical overview of elasto-viscoplastic thixotropic modeling. Journal of Non-Newtonian Fluid Mechanics. 187-188: 8-15. [DOI: 10.1016/j.jnnfm.2012.08.006]

Diamante L., Umemoto M. (2015). Rheological properties of fruits and vegetables: a review. International Journal of Food Properties. 18: 1191-1210. [DOI: 10.1080/10942912.2014.898653]

Eroglu A., Bayrambaş K., Eroglu Z., Toker O.S., Yilmaz M.T., Karaman S., Dogan M. (2016). Steady, dynamic, creep/recovery, and textural properties of yoghurt/molasses blends: temperature sweep tests and applicability of Cox–Merz rule. Food Science and Technology International. 22: 31-46. [DOI: 10.1177/1082013214566478]

Flores-Jiménez N.T., Ulloa J.A., Urías-Silvas J.E., Hidalgo-Millán A. (2023). Modification of rheological properties of animal and vegetable proteins treated with high-intensity ultrasound: a review. Food Frontiers. 4 : 700-720. [DOI: 10.1002/fft2.220]

Gilbert A., Turgeon S.L. (2021). Studying stirred yogurt microstructure and its correlation to physical properties: a review. Food Hydrocolloids. 121: 106970. [DOI: 10.1016/ j.foodhyd.2021.106970]

Guénard-Lampron V., St-Gelais D., Villeneuve S., Turgeon S.L. (2019). Individual and sequential effects of stirring, smoothing, and cooling on the rheological properties of nonfat yogurts stirred with a technical scale unit. Journal of Dairy Science. 102: 190-201. [DOI: 10.3168/jds.2018-14565]

Guénard-Lampron V., Villeneuve S., St-Gelais D., Turgeon S.L. (2020). Relationship between smoothing temperature, storage time, syneresis and rheological properties of stirred yogurt. International Dairy Journal. 109: 104742. [DOI: 10.1016/j.idairyj.2020.104742]

Heldman D.R., Lund D.B., Sabliov C. (2006). Rheological properties of foods. In: Dogan H., Kokini J.L. (Editors). Handbook of food engineering. CRC Press, Boca Raton, Florida. pp: 13-136. [DOI: 10.1201/9781420014372]

Javanmard M., Wong E., Howes T., Stokes J.R. (2018). Application of the thixotropic elasto-viscoplastic model as a structure probing technique for acid milk gel suspensions. Journal of Food Engineering. 222: 250-257. [DOI: 10.1016/j.jfoodeng.2017.11.031]

Kouřilová V., Dufková R., Hřivna L., Kumbár V. (2022). Use of rheological plastic models to describe the flow behaviour of unconventional chocolate masses. Czech Journal of Food Sciences. 40: 305-312. [DOI: 10.17221/57/2022-CJFS]

Martínez-Padilla L.P. (2024). Rheology of liquid foods under shear flow conditions: recently used models. Journal of Texture Studies. 55: e12802. [DOI: 10.1111/jtxs.12802]

Mathias T.R.D.S., De Carvalho Junior I.C., De Carvalho C.W.P., Sérvulo E.F.C. (2011). Rheological characterization of coffee-flavored yogurt with different types of thickener. Alimentos e Nutrição. 22: 521-529.

Melito H.S., Daubert C.R., Foegeding E.A. (2012). Creep and large-amplitude oscillatory shear behavior of whey protein isolate/κ-carrageenan gels. Applied Rheology. 22: 63691. [DOI: 10.3933/applrheol-22-63691]

Mullineux G., Simmons M.J.H. (2007). Effects of processing on shear rate of yoghurt, Journal of Food Engineering. 79: 850–-857. [DOI: 10.1016/j.jfoodeng.2006.03.005]

Mullineux G., Simmons M.J.H. (2008). Influence of rheological model on the processing of yoghurt. Journal of Food Engineering. 84: 250-257. [DOI: 10.1016/j. jfoodeng. 2007.05.015]

Najgebauer-Lejko D., Witek M., Żmudziński D., Ptaszek A. (2020). Changes in the viscosity, textural properties, and water status in yogurt gel upon supplementation with green and Pu-erh teas. Journal of Dairy Science. 103: 11039-11049. [DOI: 10.3168/jds.2020-19032]

National Dysphagia Diet Task Force, American Dietetic Association. (2002). National dysphagia diet: standardization for optimal care. 1st edition. American Dietetic Association, Chicago.

Ouyang K., Xie H., Wu K., Xiong H., Zhao Q. (2024). Improving fermented milk products using pH-responsive whey protein fibrils: a case study on stirred yogurt. Food Bioscience. 104507. [DOI: 10.1016/j.fbio.2024.104507]

Poursani P., Razavi S.M.A. (2023). Thickened fluids classification based on the rheological and tribological characteristics. Applied Rheology. 33: 20230102. [DOI: 10.1515/arh-2023-0102]

Szwajgier D., Gustaw W. (2015). The addition of malt to milk-based desserts: influence on rheological properties and phenolic acid content. LWT-Food Science and Technology. 62: 400-407. [DOI: 10.1016/j.lwt.2015.01.028]

Toker O.S., Karaman S., Yuksel F., Dogan M., Kayacier A., Yilmaz M.T. (2013). Temperature dependency of steady, dynamic, and creep-recovery rheological properties of ice cream mix. Food and Bioprocess Technology. 6: 2974-2985. [DOI: 10.1007/s11947-012-1005-4]

Vukić D.V., Vukić V.R., Milanović S.D., Ilicić M.D., Kanurić K.G. (2018). Modeling of rheological characteristics of the fermented dairy products obtained by novel and traditional starter cultures. Journal of Food Science and Technology. 55: 2180-2188. [DOI: 10.1007%2Fs13197-018-3135-9]

Zarzycki P., Ciołkowska A.E., Jabłońska-Ryś E., Gustaw W. (2019). Rheological properties of milk-based desserts with the addition of oat gum and κ-carrageenan. Journal of Food Science and Technology. 56: 5107-5115. [DOI: 10.1007/s13197-019-03983-4]

Yogurt is a healthy dairy product that is extensively manufactured through a standard process as a liquid/semi-solid food. The inclusion of starter cultures causes a number of biological modifications in the dairy products; converting them into various intermediate products before achieving the required three-dimensional consistency or texture (Ahmed et al., 2023). Given their strong correlation with desired qualities, including flowability, firmness, and smoothness, the internal structure and rheological properties of yogurt are critical when evaluating the quality of the final product (Atik et al., 2024). The rheological properties of yogurt are mainly affected by solids, protein, fat content, temperatures during heat treatment of milk and fermentation, homogenization pressure, etc. (Mathias et al., 2011).

Generally, the rheological properties of liquid and semi-solid foods may influence oral processing behavior (Aguayo-Mendoza et al., 2019). Research has shown that these properties impact the complex dynamic process of mastication (Chen and Lolivret, 2011), which is essential for both food intake and sensory perception, ultimately influencing consumer acceptance. In addition to shear flow measurements, oscillatory shear tests are widely employed to assess the viscoelastic characteristics of food systems (Ahmed, 2018; Melito et al., 2012; Toker et al., 2013). These tests involve subjecting samples to frequency/stress sweep, allowing for the characterization of both elastic (storage modulus, G') and viscous (loss modulus, G'') components of the material’s response to deformation.

Despite extensive investigations into the influence of rheological properties on oral processing behavior, there is a notable gap in research regarding how the rheological properties of food are affected by the process of chewing. To address this gap, this study employs experimental protocols designed to simulate the process of chewing (mastication), mirroring the sequential phases involved in human food manipulation within the mouth. These protocols allow us to replicate the dynamic nature of the chewing process, without taking into account the effect of saliva, from the initiation of forces upon the food to the gradual breakdown of food particles and eventual cessation of chewing motion. These sequential phases are replicated in this experimental setup to investigate how the rheological properties of a commercial strawberry stirred yogurt are influenced by the pseudo-chewing process. This method provides more information about how yogurt behaves in situations that closely resemble oral processing, which could assist in product development and advance our knowledge of how people perceive food texture.

Materials and methods

Studied material

The present investigation was carried out at the Technical Platform of Physico-Chemical Analysis (TPPCA) at the University pole El-Hadjeb Biskra, Algeria. Commercial strawberry stirred yogurt, in a 90 g pot; was produced and marketed in April 2023 by SOUMMAM dairy products, Bejaia, Akbou, Algeria. The main composition of this yogurt includes whole milk, reconstituted whole milk, sugar, food additives identified by the International Numbering System (1,442 thickener: Good Manufacturing Practice (GMP); 129 colorants: 0.54 mg), strawberry flavor, and Lactobacillus yeasts. Additionally, the average nutritional values per 100 g of the strawberry-stirred yogurt sample were provided by the producer as shown in Table 1.

Table 1: Average nutritional values of the commercial strawberry stirred yogurt given by the producer

| Average nutritional values | Per 100 g |

| Energy (kJ/kcal) | (390.00/92.50) |

| Fats (g) | 2.50 |

| Saturated fats (g) | 1.63 |

| Carbohydrate (g) | 14.70 |

| Sugars (g) | 11.50 |

| Proteins (g) | 2.80 |

| Salt (g) | 0.09 |

| Calcium (Ca) (mg) | 110.00 |

Rheological measurements

All the rheological measurements were performed using a controlled stress rheometer (Discovery HR 20, TA instruments, France). The rheometer is equipped with a cone and plate geometry (diameter 40 mm; angle 2°), and a stainless steel Peltier plate at a controlled temperature of 25±0.1 °C. The yogurt samples were used in their commercial form. A total of 0.6 ml of yogurt sample was used for each test measurement. The rheological properties of yogurt were studied under large (model parameters and thixotropy) and small (storage G′, loss G″ modulus, and complex viscosity) deformations. All experimental data were analyzed and fitted using MS Excel and MS Excel Solver.

To avoid any alteration to the solution structure, the sample was meticulously placed on the rheometer’s measurement plate, and the upper plate was then progressively lowered into the correct position. When the samples are positioned within the measurement geometry, their structural condition is influenced by their history of shear deformation and can appear to be ambiguous. To prevent any memory influence and to ensure measurement reproducibility, the samples must be in the same initial state, often known as the ‘reference state’.

Shear flow measurements (Protocol F)

Protocol F is accomplished in four experimental steps:

Step 1: first, the sample was positioned under the measurement geometry before applying a pre-shear rate of 10 s at 10 1/s. The aim of this step is to improve the reliability of experimental results by limiting possible memory effects of the sample. To promote restoration of its initial structure, the sample underwent a five min resting period post-pre-shearing, thus minimizing the influence of any transient effects and ensuring a more accurate representation during subsequent measurements.

Step 2: the typical experimental procedure involved three sequential steps, starting with 15 min of applied shear rate ramp from 1/105 to 400 1/s. This linearly increasing ramp of shear rate allowed forming the ascending part (upward) of the flow curve.

Step 3: in this step, the system reached a plateau known as the peak hold phase. During the peak hold phase, the samples were maintained at the maximum shear rate for 15 min. This step enabled observation of material behavior under sustained shear rate conditions.

Step 4: in this phase, the rheometer reversed the ramp, with the applied shear rate linearly decreasing from 400 to 1/105 1/s to measure the downward flow curve. This step completed the comprehensive characterization of the material rheological behavior under decreasing shear rates.

Both upward and downward rheogrammes are fitted by a Herschel-Bulkley rheological model using MS Excel Solver. The Herschel-Bulkley model is expressed in equation 1 (Vukić et al., 2018):

(1)

(1)Where is the shear stress (Pa); 0 is the yield stress (Pa); γ ̇ is the shear rate (1/s); k is the consistency coefficient (Pa.sn), and n is the flow behavior index signifying the extent of deviation from Newtonian behavior. The Herschel-Bulkley model was selected due to its ease of use and capacity to measure yield stress. In addition, this model is recognized as one among several models available in the literature, commonly used to describe the rheological flow curves of various food products (Martínez-Padilla, 2024). For example, it has been used to model experimental rheological flow curves of chocolate (Kouřilová et al., 2022) and yogurt during production (Mullineux and Simmons, 2007, 2008).

Dynamic rheological measurements

Dynamic oscillatory measurements were used to determine the viscoelastic properties of stirred yogurt in the linear viscoelastic region in a pre-yield state. The dynamic tests were carried out before and after shearing the sample at a shear rate of 400 1/s for 15 min to study the effect of the pseudo-chewing process on yogurt in the mouth. For the oscillatory mode, two protocols were considered:

-Protocol D1

The sample was first loaded into the measuring device, and then the protocol D1 was executed in four steps:

Step 1: the sample was pre-sheared for 10 s at an imposed shear rate of 10 1/s to control the memory effect. Subsequently, the sample was rested for five min before starting the experiment to establish thermal equilibrium and relieve additional stresses caused by the loading.

Step 2: since the rheometer used in this study is an imposed stress rheometer, the controlled shear stress approach was selected as a mode of operation for presetting the deflection. A stress sweep test was performed at an angular frequency of 10 rad/s; the stress was varied from 0.01 to 100 Pa in order to determine the linear viscoelastic region.

Step 3: the sample was sheared for 15 min at a shear rate of 400 1/s. The purpose of the shearing is to simulate the pseudo-chewing process.

Step 4: similar to step (2), the stress sweep test was performed under the same conditions, i.e., an angular frequency of 10 rad/s and the stress was varied from 0.01 to 100 Pa. This step was performed in order to determine the linear viscoelastic region after shearing the sample, i.e., after the simulated pseudo-chewing process.-Protocol D2

Step 1: to eliminate any potential internal tensions in the sample prior to measurement, it was pre-sheared for 10 s at an imposed shear rate of 10 1/s, followed by five min of rest.

Step 2: as in protocol D1, the shear stress approach was selected for presetting the deflection. The frequency sweep test was performed using a shear stress amplitude of 0.2 Pa, within the linear viscoelastic region, obtained using protocol D1. These dynamic oscillatory tests were performed, with a frequency range of 0.1 to 100 Hz, to evaluate storage (G′), loss (G″), complex modulus (G*), and mixed dynamic viscosity (η*).

Step 3: shearing sample at a shear rate of 400 1/s for 15 min.

Step 4: this step is similar to step (2), launched after shearing the sample, i.e., after the simulated pseudo-chewing process.

Results and discussions

Shear flow analysis

The experimental protocol F employed in this study serves to simulate the process of chewing (mastication), without taking into account the effect of saliva, akin to how humans manipulate food within their mouths. In the act of pseudo-chewing, individuals initiate the process by exerting forces on the food as they begin to consume it. These initial forces are gradually increased to break down the food particles, mimicking the early stages of mastication. Subsequently, a plateau phase is reached during which the applied forces are sustained to thoroughly grind and process the food. Finally, the forces are gradually reduced and eventually ceased, representing the termination of the pseudo-chewing motion. These sequential phases were replicated within the experimental setup with the aim of capturing the dynamic nature of the pseudo-chewing process. This approach allows us to investigate how the rheological properties of yogurt are influenced by pseudo-chewing. Understanding these interactions can offer valuable insights into yogurt’s behavior under conditions that closely mimic oral processing, potentially informing product formulation and enhancing our understanding of food texture perception.

In this study, the rheological behavior of the material was examined by applying Protocol F, where shear stress and apparent viscosity were plotted as functions of the applied shear rate. The exploration of thixotropic properties was conducted by analyzing the hysteresis loop areas generated during a three-step experiment encompassing the upward curve, plateau, and downward curve phases. The flow curves of strawberry stirred yogurt, i.e., shear stress () as a function of shear rate (γ ̇), studied at 25±0.1 °C, are presented in Figure 1 as open points. The examined yogurt rheological flow curves displayed a clear yield stress and a hysteresis loop. The area between the curves measures the extent and time-dependent nature of thixotropy in the sample. The calculated thixotropy index of stirred yogurt is 48% (Figure 1), indicating the energy needed to break the reversible microstructure of the tested material. This result is similar to the findings obtained by Vukić et al. (2018) who reported a coefficient of thixotropic breakdown of 66% for the yogurt sample. Thus, the flow curves in Figure 1 lead to conclude that strawberry stirred yogurt is a yield stress non-Newtonian fluid with shear-thinning and thixotropic time-dependent flow characteristics.

Both upward and downward shear stress curves in Figure 1 are well described by Herschel-Bulkley rheological law with R2>0.98, presented by solid lines. The Herschel-Bulkley model shown in equation 1, and the values of its parameters were calculated (Vukić et al., 2018).

.PNG)

Figure 1: Flow behavior curves of strawberry stirred yogurt according to the protocol F; (a): linear plot; (b): logarithmic plot

Table 2 presents the values of the rheological parameters obtained from fitting the Herschel-Bulkley model. As shown in Table 2, the flow index value (n) of the yogurt, obtained from fitting the Herschel-Bulkley model, ranged from 0 to 1, indicating that the rheological behavior of the strawberry stirred yogurt sample is shear-thinning (n<1), thereby affirming its non-Newtonian and shear-thinning nature. The yield stress, defined as the lowest stress value necessary to cause the material to flow (De Souza Mendes and Thompson, 2012), was identified as the starting point of the flow curves. The yield stress difference between increasing and decreasing ramps for yogurt, as shown in Table 2, is attributed to structural breakdown induced by the applied shear rate during the experimental test. Since yogurt exhibits pseudoplastic and thixotropic rheological properties, applying shear rate leads to breakdown of its internal structure, which can be restructured by allowing the fluid to rest. Consequently, the yield stress encountered during the increasing ramp of 5 Pa is higher than that obtained during the decreasing ramp of 1 Pa. After pre-shearing the sample, a decrease in the consistency coefficient of yogurt was observed, which is a consequence of structural breakdown during the shearing process. Similar flow behavior has been reported by other researchers for yogurt (Gilbert and Turgeon 2021; Javanmard et al., 2018; Najgebauer-Lejko et al., 2020).

Table 2: The Herschel-Bulkley parameters of strawberry stirred yogurt sample

| T0 (Pa) | k (Pa.s) | n | R2 | |

| Increasing shear rate (Upward-curve) | 6 | 4.15 | 0.54 | 0.98 |

| Decreasing shear rate (Downward-curve) |

1 | 2.61 | 0.48 | 0.99 |

A product is subjected to a variety of shear rates throughout industrial activities, and to properly design the equipment for these procedures, it is crucial to understand how the viscosity changes with shear rates (Álvarez et al., 2006). In other words, viscosity is one of the key quality parameters affecting sensory characteristics of fermented dairy products (Vukić et al., 2018).

It is critical to characterize the time-dependent rheological properties of food systems to build connections between flow and structure, and to link physical characteristics with sensory assessment. The viscosity of stirred yogurt as a function of shear rate is presented in Figure 2. The experimental results are also presented in Figure 1. As the shear rate increases, the viscosity decreases, which can be explained by the material structure reorganizing at a greater shear rate. Initially, as the shear rate increases, viscosity decreases, indicating the pseudoplastic behavior of the material. Notably, viscosity decreases even during the plateau phase when the shear rate remains unchanged. This phenomenon suggests ongoing structural breakdown within the yogurt, which contributes to diminishing viscosity. The decreasing viscosity of yogurt may be attributed to the continuous structural breakdown. This behavior is attributed to the thixotropic nature of yogurt, wherein the internal structure undergoes reformation following shear-induced breakdown. Moreover, viscosity exhibits greater values (0.85 Pa.s at shear rate of 50 1/s) during the shear rate ascending ramp as opposed to the lowering ramp (0.37 Pa.s at shear rate of 50 1/s). This disparity underscores the impact of shear history on yogurt rheology, with the structured sample exhibiting greater resistance to flow than to the destructured sample.

In the medical field, the International Dysphagia Diet Standardization Initiative (IDDSI) framework includes specific terms for food liquids that correlate them with viscosity ranges measured at 25 °C and a shear rate of 50 1/s. This mean value corresponds to the shear rate in the oral cavity. The classifications are as follows: Thin liquids with viscosities ranging from 1/103 to 0.05 Pa.s, nectar-like liquids ranging from 0.05 to 0.35 Pa.s, honey-like liquids ranging from 0.35 to 1.75 Pa.s, and spoon-thick liquids with viscosities greater than 1.75 Pa.s (National Dysphagia Diet Task Force and American Dietetic Association, 2002; Poursani and Razavi, 2023). In this study, viscosities measured at a shear rate of 50 1/s are 0.85 and 0.37 Pa.s during increasing and decreasing ramps, respectively. Therefore, the viscosities, ranging between 0.35 and 1.75 Pa.s, can classify the studied strawberry stirred yogurt as a honey-like semisolid food. This result confirms findings by Vukić et al. (2018), who reported apparent yogurt viscosities between 0.41 and 0.60 Pa.s; thus the product was also classified as honey-like.

Figure 2: Variation of viscosity as a function of shear rate for strawberry stirred yogurt according to protocol F

Dynamic rheological analysis

In viscoelasticity measurements, it is crucial to operate within the linear viscoelastic region to study the material in a structured state close to its resting state. The material is thus easily deformed, while its internal structure remains intact, with the applied stresses sufficiently low to prevent the rupture of inter-particle bonds. To ensure this, preliminary tests are necessary to define the ranges of applied stresses and the corresponding deformations for given stresses. Figure 3 illustrates measurements used to determine the linear viscoelastic region of the sample according to protocol D1. Stress sweeps are performed, between 0.01 and 100 Pa, while fixing the frequency at 1.6 Hz, and the resulting deformations are measured. This allows for establishing the linear viscoelastic region, or the stress range for which G' and G'' respond linearly.

Figures 3a and b illustrate the evolution of storage modulus (G') and loss modulus (G''), as functions of oscillation strain, respectively without and with pre-shearing of the sample to simulate the pseudo-chewing process. The values of these different parameters are higher without pre-shearing the sample. The strain at which the sample transitions from elastic to viscous behavior is also higher without pre-shearing compared to when no pre-shear is applied. This difference can be attributed to breakdown of the structured nature of the sample induced by shearing. When pre-shear is applied, the internal structure of the sample is disrupted, making it more susceptible to transitioning into the viscous domain under lower stress levels. Consequently, less force is required to induce transition into the viscous domain.

Moreover, the plateaus in storage modulus G' and loss modulus G'' are observed in Figures 3a and b with G' value higher than G''. These observations indicate typical behavior of viscoelastic materials such as gels and dispersions (Eroglu et al., 2016; Zarzycki et al., 2019). However, transition to the viscous domain occurs at these same levels of oscillation strain of one and five percent. A loss of linearity in moduli G' and G'' is observed, followed by a crossover, where storage modulus G' values become lower than loss modulus G''.

.PNG)

Figure 3: Oscillation strain limit of the linear viscoelastic region of strawberry stirred yogurt using the protocol D1 with an angular frequency of 10 rad/s (~1.6 Hz); variation of G' and G''as functions of oscillation strain; (a): without, and (b): with pre-shearing

Figure 4a and b show the evolution of complex modulus (G*) and complex viscosity (η*) as functions of strain without and with pre-shearing of the sample, respectively, according to the protocol D1. The values of complex modulus and complex viscosity are lower for the sample that underwent pre-shear test compared to the non pre-sheared sample.

.PNG)

Figure 4: Evolution of (a): complex modulus (G*), and (b): complex viscosity (η*) as functions of strain without and with pre-shearing of strawberry stirred yogurt (using the protocol D1 with an angular frequency of 10 rad/s (~1.6 Hz))

The viscoelastic characteristics of the studied stirred yogurt were determined using the frequency sweep technique. The experimental data obtained are presented as the evolution of storage modulus (G′), loss modulus (G″), complex modulus (G*), complex viscosity (η*), and loss tangent (tan δ) as functions of frequency. In a standard oscillatory experimental test, referred to as a frequency sweep, the stirred yogurt samples were exposed to an increasing frequency range from 0.1 to 100 Hz while the shear stress amplitude was maintained at 0.2 Pa.

All samples exhibited frequency-dependent behavior, with both storage modulus (G') and loss modulus (G'') increasing as the frequency increased (Figure 5a). This frequency-dependent response is characteristic of viscoelastic materials (Vukić et al., 2018), where the material’s ability to store and dissipate energy varies with the rate at which it is subjected to oscillatory forces. The frequency dependence observed in both storage modulus (G') and loss modulus (G'') of the samples signifies their classification as physical gels. Physical gels typically exhibit pronounced frequency dependence. This frequency dependence suggests that the yogurt samples possess a network structure capable of storing and dissipating energy typical of physical gels. G' was larger than G'' at all investigated frequencies, suggesting that the stirred yogurt is a solid viscoelastic material.

The characterization of the samples as physical gels, based on the frequency dependence of their storage and loss moduli, is further supported by loss tangent analysis. The loss tangent serves as a widely recognized metric for elucidating the viscoelastic behavior of materials, providing insight into their inherent viscous or elastic properties. A loss tangent greater than one indicates liquid viscoelastic behavior, where the sample exhibits more viscous characteristics. Conversely, a loss tangent lower than one suggests solid viscoelastic behavior, indicative of more elastic properties. Figure 5b shows the evolution of loss tangent as a function of frequency. The loss tangent of the studied samples of stirred yogurt was lower than one at all investigated frequencies, indicating their solid viscoelastic behavior and confirming the results shown in Figure 5a.

To explore the pseudo-chewing process, two samples were examined: one underwent pre-shearing, whereas the other did not. As anticipated, storage modulus (G') and loss modulus (G'') magnitudes as a function of frequency for the pre-sheared sample were lower than those for the sample without pre-shear (Figure 5a). This reduction in modulus magnitudes suggests that pre-shearing resulted in internal structural breakdown within the sample, leading to decreased resistance to deformation. However, the magnitude of loss tangent for the pre-sheared sample was higher than that for the sample without pre-shear (Figure 5b).

Figures 6a and b depict the evolution of G* (complex modulus) and η* (complex viscosity) as functions of frequency. It is evident that as frequency increases, G* also increases, indicating a frequency-dependent behavior (Figure 6a). This observation aligns with previous findings regarding the frequency dependence of G' and G'' (Figure 5a), suggesting that G* exhibits similar behavior. However, the same figure shows that applying pre-shear to a sample of stirred yogurt results in a decrease in G*, indicating a reduction in the material's overall firmness.

Notably, Figure 6b shows that the complex viscosity (η*) decreases as frequency increases. This phenomenon signifies that the material exhibits less resistance to flow at higher frequencies. Furthermore, the viscosity of the sample subjected to pre-shear is lower than that of the sample which is not subjected to pre-shear. This indicates that pre-shearing induces a reduction in viscosity due to internal structural breakdown within the sample.

.PNG)

Figure 5: Frequency sweep of strawberry stirred yogurt sample without and with pre-shearing according to the protocol D2; (a): storage and loss moduli (G' and G''); (b): loss tangent (tan δ)

.PNG)

Figure 6: The viscoelastic proprieties of strawberry stirred yogurt (frequency sweep) without and with pre-shearing according to the protocol D2; a: complex modulus (G*); b: complex viscosity (η*)

Conclusion

This study investigated the impact of the chewing process, without taking into account the effect of saliva, on the rheological properties of stirred commercial yogurt. By utilizing both steady and dynamic tests, the mechanical behavior of yogurt samples under pseudo-chewing was analyzed. The flow curves analysis revealed non-Newtonian shear-thinning behavior and time-dependent (thixotropic) properties of the stirred yogurt, while dynamic test demonstrated its viscoelastic properties.

Simulating the pseudo-chewing process through the chosen experimental protocols uncovered a notable decrease in viscosity, attributed to the destruction of internal structure of the yogurt. The findings indicate significant alterations in rheological parameters such as complex modulus (G*), complex viscosity (η*), and loss tangent (tan δ) in response to the pseudo-chewing process. Notably, pre-shearing induced changes in G* and η*, indicating modifications in the firmness and flow characteristics of the yogurt that affect its sensory properties. These findings contribute to improved product formulation and texture optimization by enhancing our understanding of the mechanical responses of yogurt during the pseudo-chewing process. This knowledge can assist producers in modifying their products to make them safer, easier to swallow, and more palatable. Furthermore, expanding the study to include a broader range of yogurt formulations and other food products would help generalize these findings.

Author contributions

A.B. and K.B. designed the study; G.B., A.B., K.L., and M.Y. conducted the experimental work; G.B., A.B., A.B., K.L., M.Y., I.M.M., and K.B. analyzed the data; A.B. and A.B. wrote, reviewed, and edited the manuscript. A.B. supervised the research. All authors read and approved the final manuscript.

Conflicts of Interest

The authors declare that there is no conflict of interest.

Acknowledgements

The authors wish to thank the director of the Plateau Technique d'Analyse Physico-Chimiques (Biskra-CRAPC), Professor Abderrezak Debilou, for his active support.

Funding

This study is a part of PRFU project A11N01UN070120220002 registered in the Directorate General of Scientific Research and Technological Development (DGRSDT) of the Algerian Ministry of Higher Education and Scientific Research. This research did not receive any specific grant from funding agencies.

Ethical consideration

Not applicable.

References

Aguayo-Mendoza M.G., Ketel E.C., Van Der Linden E., Forde C.G., Piqueras-Fiszman B., Stieger M. (2019). Oral processing behavior of drinkable, spoonable and chewable foods is primarily determined by rheological and mechanical food properties. Food Quality and Preference. 71: 87-95. [DOI: 10.1016/j.foodqual.2018.06.006]

Aguilar-Raymundo V.G., Vélez-Ruiz J.F. (2018). Physicochemical and rheological properties of a dairy dessert, enriched with chickpea flour. Foods. 7: 25. [DOI: 10.3390/foods7020025]

Ahmed J. (2018). Advances in rheological measurements of food products. Current Opinion in Food Science. 23: 127-132. [DOI: 10.1016/j.cofs.2018.10.007]

Ahmed J., Barua S., Roy S. (2023). Rheology and microstructure of yogurt. In: Ahmed J., Basu S. (Editors). Advances in food rheology and its applications. Woodhead Publishing, Sawston, Cambridge. pp: 335-363. [DOI: 10.1016/B978-0-12-823983-4.00020-0]

Álvarez E., Cancela M.A., Maceiras R. (2006). Effect of temperature on rheological properties of different jams. International Journal of Food Properties. 9: 135-146. [DOI: 10.1080/10942910500473996]

Atik D.S., Öztürk H.İ., Akın N. (2024). Perspectives on the yogurt rheology. International Journal of Biological Macromolecules. 263: 130428. [DOI: 10.1016/j.ijbiomac.2024.130428]

Chen J., Lolivret L. (2011). The determining role of bolus rheology in triggering a swallowing. Food Hydrocolloids. 25: 325-332. [DOI: 10.1016/j.foodhyd.2010.06.010]

De Souza Mendes P.R., Thompson R.L. (2012). A critical overview of elasto-viscoplastic thixotropic modeling. Journal of Non-Newtonian Fluid Mechanics. 187-188: 8-15. [DOI: 10.1016/j.jnnfm.2012.08.006]

Diamante L., Umemoto M. (2015). Rheological properties of fruits and vegetables: a review. International Journal of Food Properties. 18: 1191-1210. [DOI: 10.1080/10942912.2014.898653]

Eroglu A., Bayrambaş K., Eroglu Z., Toker O.S., Yilmaz M.T., Karaman S., Dogan M. (2016). Steady, dynamic, creep/recovery, and textural properties of yoghurt/molasses blends: temperature sweep tests and applicability of Cox–Merz rule. Food Science and Technology International. 22: 31-46. [DOI: 10.1177/1082013214566478]

Flores-Jiménez N.T., Ulloa J.A., Urías-Silvas J.E., Hidalgo-Millán A. (2023). Modification of rheological properties of animal and vegetable proteins treated with high-intensity ultrasound: a review. Food Frontiers. 4 : 700-720. [DOI: 10.1002/fft2.220]

Gilbert A., Turgeon S.L. (2021). Studying stirred yogurt microstructure and its correlation to physical properties: a review. Food Hydrocolloids. 121: 106970. [DOI: 10.1016/ j.foodhyd.2021.106970]

Guénard-Lampron V., St-Gelais D., Villeneuve S., Turgeon S.L. (2019). Individual and sequential effects of stirring, smoothing, and cooling on the rheological properties of nonfat yogurts stirred with a technical scale unit. Journal of Dairy Science. 102: 190-201. [DOI: 10.3168/jds.2018-14565]

Guénard-Lampron V., Villeneuve S., St-Gelais D., Turgeon S.L. (2020). Relationship between smoothing temperature, storage time, syneresis and rheological properties of stirred yogurt. International Dairy Journal. 109: 104742. [DOI: 10.1016/j.idairyj.2020.104742]

Heldman D.R., Lund D.B., Sabliov C. (2006). Rheological properties of foods. In: Dogan H., Kokini J.L. (Editors). Handbook of food engineering. CRC Press, Boca Raton, Florida. pp: 13-136. [DOI: 10.1201/9781420014372]

Javanmard M., Wong E., Howes T., Stokes J.R. (2018). Application of the thixotropic elasto-viscoplastic model as a structure probing technique for acid milk gel suspensions. Journal of Food Engineering. 222: 250-257. [DOI: 10.1016/j.jfoodeng.2017.11.031]

Kouřilová V., Dufková R., Hřivna L., Kumbár V. (2022). Use of rheological plastic models to describe the flow behaviour of unconventional chocolate masses. Czech Journal of Food Sciences. 40: 305-312. [DOI: 10.17221/57/2022-CJFS]

Martínez-Padilla L.P. (2024). Rheology of liquid foods under shear flow conditions: recently used models. Journal of Texture Studies. 55: e12802. [DOI: 10.1111/jtxs.12802]

Mathias T.R.D.S., De Carvalho Junior I.C., De Carvalho C.W.P., Sérvulo E.F.C. (2011). Rheological characterization of coffee-flavored yogurt with different types of thickener. Alimentos e Nutrição. 22: 521-529.

Melito H.S., Daubert C.R., Foegeding E.A. (2012). Creep and large-amplitude oscillatory shear behavior of whey protein isolate/κ-carrageenan gels. Applied Rheology. 22: 63691. [DOI: 10.3933/applrheol-22-63691]

Mullineux G., Simmons M.J.H. (2007). Effects of processing on shear rate of yoghurt, Journal of Food Engineering. 79: 850–-857. [DOI: 10.1016/j.jfoodeng.2006.03.005]

Mullineux G., Simmons M.J.H. (2008). Influence of rheological model on the processing of yoghurt. Journal of Food Engineering. 84: 250-257. [DOI: 10.1016/j. jfoodeng. 2007.05.015]

Najgebauer-Lejko D., Witek M., Żmudziński D., Ptaszek A. (2020). Changes in the viscosity, textural properties, and water status in yogurt gel upon supplementation with green and Pu-erh teas. Journal of Dairy Science. 103: 11039-11049. [DOI: 10.3168/jds.2020-19032]

National Dysphagia Diet Task Force, American Dietetic Association. (2002). National dysphagia diet: standardization for optimal care. 1st edition. American Dietetic Association, Chicago.

Ouyang K., Xie H., Wu K., Xiong H., Zhao Q. (2024). Improving fermented milk products using pH-responsive whey protein fibrils: a case study on stirred yogurt. Food Bioscience. 104507. [DOI: 10.1016/j.fbio.2024.104507]

Poursani P., Razavi S.M.A. (2023). Thickened fluids classification based on the rheological and tribological characteristics. Applied Rheology. 33: 20230102. [DOI: 10.1515/arh-2023-0102]

Szwajgier D., Gustaw W. (2015). The addition of malt to milk-based desserts: influence on rheological properties and phenolic acid content. LWT-Food Science and Technology. 62: 400-407. [DOI: 10.1016/j.lwt.2015.01.028]

Toker O.S., Karaman S., Yuksel F., Dogan M., Kayacier A., Yilmaz M.T. (2013). Temperature dependency of steady, dynamic, and creep-recovery rheological properties of ice cream mix. Food and Bioprocess Technology. 6: 2974-2985. [DOI: 10.1007/s11947-012-1005-4]

Vukić D.V., Vukić V.R., Milanović S.D., Ilicić M.D., Kanurić K.G. (2018). Modeling of rheological characteristics of the fermented dairy products obtained by novel and traditional starter cultures. Journal of Food Science and Technology. 55: 2180-2188. [DOI: 10.1007%2Fs13197-018-3135-9]

Zarzycki P., Ciołkowska A.E., Jabłońska-Ryś E., Gustaw W. (2019). Rheological properties of milk-based desserts with the addition of oat gum and κ-carrageenan. Journal of Food Science and Technology. 56: 5107-5115. [DOI: 10.1007/s13197-019-03983-4]

* Corresponding author (A. Benslimane)

* E-mail: abdelhakim.benslimane@univ-bejaia.dz

ORCID ID: https://orcid.org/0000-0002-6554-6309

* E-mail: abdelhakim.benslimane@univ-bejaia.dz

ORCID ID: https://orcid.org/0000-0002-6554-6309

Type of Study: Original article |

Subject:

Special

Received: 24/07/16 | Accepted: 24/12/03 | Published: 24/12/30

Received: 24/07/16 | Accepted: 24/12/03 | Published: 24/12/30

References

1. Aguayo-Mendoza M.G., Ketel E.C., Van Der Linden E., Forde C.G., Piqueras-Fiszman B., Stieger M. (2019). Oral processing behavior of drinkable, spoonable and chewable foods is primarily determined by rheological and mechanical food properties. Food Quality and Preference. 71: 87-95. [DOI: 10.1016/j.foodqual.2018.06.006] [DOI:10.1016/j.foodqual.2018.06.006]

2. Aguilar-Raymundo V.G., Vélez-Ruiz J.F. (2018). Physicochemical and rheological properties of a dairy dessert, enriched with chickpea flour. Foods. 7: 25. [DOI: 10.3390/foods7020025] [DOI:10.3390/foods7020025] [PMID] [PMCID]

3. Ahmed J. (2018). Advances in rheological measurements of food products. Current Opinion in Food Science. 23: 127-132. [DOI: 10.1016/j.cofs.2018.10.007] [DOI:10.1016/j.cofs.2018.10.007]

4. Ahmed J., Barua S., Roy S. (2023). Rheology and microstructure of yogurt. In: Ahmed J., Basu S. (Editors). Advances in food rheology and its applications. Woodhead Publishing, Sawston, Cambridge. pp: 335-363. [DOI: 10.1016/B978-0-12-823983-4.00020-0] [DOI:10.1016/B978-0-12-823983-4.00020-0]

5. Álvarez E., Cancela M.A., Maceiras R. (2006). Effect of temperature on rheological properties of different jams. International Journal of Food Properties. 9: 135-146. [DOI: 10.1080/10942910500473996] [DOI:10.1080/10942910500473996]

6. Atik D.S., Öztürk H.İ., Akın N. (2024). Perspectives on the yogurt rheology. International Journal of Biological Macromolecules. 263: 130428. [DOI: 10.1016/j.ijbiomac.2024.130428] [DOI:10.1016/j.ijbiomac.2024.130428] [PMID]

7. Chen J., Lolivret L. (2011). The determining role of bolus rheology in triggering a swallowing. Food Hydrocolloids. 25: 325-332. [DOI: 10.1016/j.foodhyd.2010.06.010] [DOI:10.1016/j.foodhyd.2010.06.010]

8. De Souza Mendes P.R., Thompson R.L. (2012). A critical overview of elasto-viscoplastic thixotropic modeling. Journal of Non-Newtonian Fluid Mechanics. 187-188: 8-15. [DOI: 10.1016/j.jnnfm.2012.08.006] [DOI:10.1016/j.jnnfm.2012.08.006]

9. Diamante L., Umemoto M. (2015). Rheological properties of fruits and vegetables: a review. International Journal of Food Properties. 18: 1191-1210. [DOI: 10.1080/10942912.2014.898653] [DOI:10.1080/10942912.2014.898653]

10. Eroglu A., Bayrambaş K., Eroglu Z., Toker O.S., Yilmaz M.T., Karaman S., Dogan M. (2016). Steady, dynamic, creep/recovery, and textural properties of yoghurt/molasses blends: temperature sweep tests and applicability of Cox-Merz rule. Food Science and Technology International. 22: 31-46. [DOI: 10.1177/1082013214566478] [DOI:10.1177/1082013214566478] [PMID]

11. Flores-Jiménez N.T., Ulloa J.A., Urías-Silvas J.E., Hidalgo-Millán A. (2023). Modification of rheological properties of animal and vegetable proteins treated with high-intensity ultrasound: a review. Food Frontiers. 4 : 700-720. [DOI: 10.1002/fft2.220] [DOI:10.1002/fft2.220]

12. Gilbert A., Turgeon S.L. (2021). Studying stirred yogurt microstructure and its correlation to physical properties: a review. Food Hydrocolloids. 121: 106970. [DOI: 10.1016/ j.foodhyd.2021.106970] [DOI:10.1016/j.foodhyd.2021.106970]

13. Guénard-Lampron V., St-Gelais D., Villeneuve S., Turgeon S.L. (2019). Individual and sequential effects of stirring, smoothing, and cooling on the rheological properties of nonfat yogurts stirred with a technical scale unit. Journal of Dairy Science. 102: 190-201. [DOI: 10.3168/jds.2018-14565] [DOI:10.3168/jds.2018-14565] [PMID]